Chuzhou Huihuang Nonwoven Technology Co., Ltd. |

|

Verified Suppliers

|

|

Professional SMS SMMS SXS PP spunbond Nonwoven production line for surgical gown cap shoe cover

HHM non woven technology is profession manufacture in non woven fabric making line S SS SSS SMS SMMS SXS .

| Machine Model | Reifenhauser Reicofil 3/4,Spunbond lines, spun-melt lins S, SS,SSS, SXS,SXXS,SMMS ,SMS ,SSMMS |

| Machine Size | 18m-60m(L)*10m-31m(W)*10m-12m(H) |

| Raw Material required | PP(polypropylene),additives MFI/MFR:25-40g/10min(spunbonding process) MFI/MFR:800-2000g/10min (Melt-blowning process) |

| Effective width | 1600mm,2400mm,3200mm,4000mm,4800mm customizable width by requirements |

| Max Speed | 150m/mn-550m/min |

| Transformer&Power consumption | Transformer require:200KVA-3000KVA Power consumption :500KWH/Ton-1400KWH/Ton |

| Output per year | 1500 Tons - 10000 Tons |

| Products GSM | 8gsm-250 gsm |

| Applications of products | Industrial:Shopping bags, furniture ,agriculture ,packageing,etc Medical:Surgical gown /cap /sheet /mask ,etc Hygiene: Diapers ,sanitary ,napking , etc. |

1) Parts of spunbonded nonwoven fabric production line:

Recycle extruder---->Main extruder---->Filter---->Metering pump---->Monomer suction device--->Spinning box(ENKA/KASEN spinneret)---->

Quenching air chamber---->Stretching device---->Web former---->Calender---->Winder---->Slitter

2) Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)---->Raw material----> Melting---->Filtering---->Measuring ---->Spinning---->Cooling---->Stretching---->

Web forming---->Calendering---->Winding----> Cutting---->Final product

Main parts of non woven system

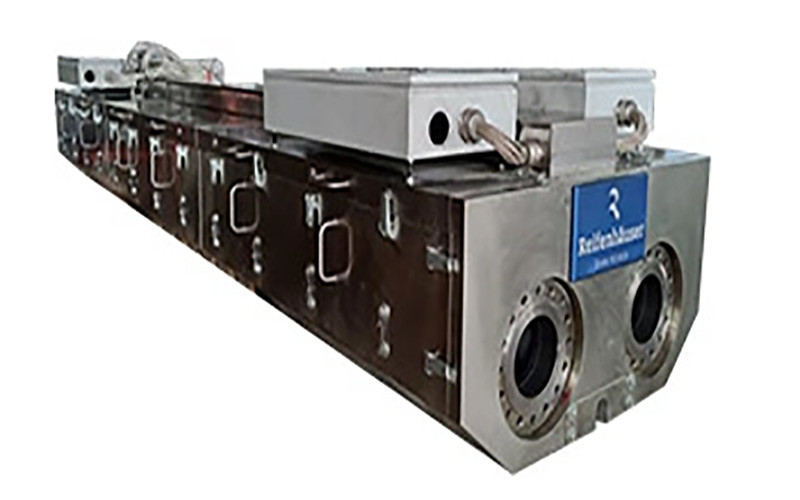

Name Melt blown spinning beam

Material : sus 630

Spinneret hole :0.32 - 0.5 mm

Fabric weight 2 -200n grams

Original :GERMANY/JAPA

Name automatic winding machine

Effective width : 1600 /2400/3200 mm

Rolling Speed : 200 - 400 M/Minute

Rolling Diameter : 2000 mm

Original : CHINA

Name : Spinneret

Spinneret width : 256 mm

Hole size : 0.45 nmm

Hole Qty : 12350 - 24500 pcs

Material : SUS 431

Original : CHINA / GERMANY

Name upper / down drafting unit

Effective Width : 1600 / 2400 / 3200 mm

Filament fineness : 1.6 - 2.4 Denier

Original : CHINA

Name :Extrusion Machine

Model : ¢130 / 150 / 170

Heating System :electricity heating

Drive Motor : Siemens

Original : CHINA

Name : Raw material dosing machine

Weight system : by weight

Hopper :4 pcs

Accuracy : 0.01 %

Feeding percentage :1 - 99 %

Original: USA / ITALY

Name : Spinning beam

Model : 1600 / 2400 / 3200 mm

Heating System : Oil / Electricity Heating

Distribution Design :big hanger type

Original : CHINA

Precisely CNC center hold machine parts beyond customoer request

Exhibition show with customer

FAQ