Chuzhou HH Non Woven Technology CO.,LTD |

|

Verified Suppliers

|

antibacterial softness SMS SMMS SS SSS spunbond meltblown PP polypropylene non woven production line

Date base

| Model | Effective Width | Weight Range | Output per day | Machine speed | Tranformer | Power consumption | Machine Size |

| HHM-1.6SMS | 1.6M | 9-100G/M2 | 6-10Ton | ≦350m/min | ≈800KVA | 1300º-1600º/Ton | 45M*20M*12M |

| HHM-2.4SMMS | 2.4M | 9-100G/M2 | 10-15Ton | ≦350m/min | ≈1250KVA | 1300º-1600º/Ton | 45M*23M*12M |

| HHM-3.2SMMS | 3.2M | 9-100G/M2 | 12-20Ton | ≦350m/min | ≈1600KVA | 1300º-1600º/Ton | 45M*25M*12M |

| HHM-4.0SMMS | 4.0M | 9-100G/M2 | 15-25Ton | ≦350m/min | ≈2000KVA | 1300º-1600º/Ton | 45M*28M*12M |

| HHM-4.8SMMS | 4.8M | 9-100G/M2 | 18-30Ton | ≦350m/min | ≈1000+1250KVA | 1300º-1600º/Ton | 4 5M*31M*12M |

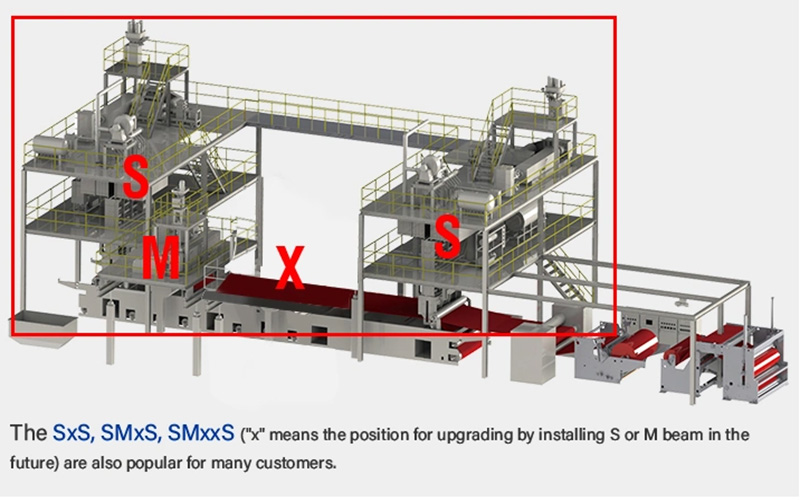

| Machine Model | Reifenhauser Reicofil 3/4,Spunbond lines, spun-melt lins S, SS,SSS, SXS,SXXS,SMMS ,SMS ,SSMMS |

| Machine Size | 18m-60m(L)*10m-31m(W)*10m-12m(H) |

| Raw Material required | PP(polypropylene),additives MFI/MFR:25-40g/10min(spunbonding process) MFI/MFR:800-2000g/10min (Melt-blowning process) |

| Effective width | 1600mm,2400mm,3200mm,4000mm,4800mm customizable width by requirements |

| Max Speed | 150m/mn-550m/min |

| Transformer&Power consumption | Transformer require:200KVA-3000KVA Power consumption :500KWH/Ton-1400KWH/Ton |

| Output per year | 1500 Tons - 10000 Tons |

| Products GSM | 8gsm-250 gsm |

| Applications of products | Industrial:Shopping bags, furniture ,agriculture ,packageing,etc Medical:Surgical gown /cap /sheet /mask ,etc Hygiene: Diapers ,sanitary ,napking , etc. |

| Spunmelt Composite Nonwovens Mainly Applications | |

| Nonwoven Medical Product | Surgical drapes ,Surgeon’s mask ,etc . |

| Nonwoven Hygiene Product | Baby and adult diapers |

| Work protection product | Protctive clothing , breathing masks |

| Nonwoven Filtration product | Protective clothing , breathing masks |

Process flow:

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

Installed power: 600KW

Web width: 3200mm

Max. winding diameter: ф1200mm

Annual output: 3000tons (50g/m2)

Single filament titer: ≤2.5 denier

Web weight: 10-200g/m2

Max. mechanical speed: 0-120m/min (Process speed:10-100m/min)

Electric consume: 700KWH(for 1ton product)

Workers and power

Number of workers: 3-4persons

External power supply: 500KVA

Water system: 0.2Mpa

Sms fabric is Durability, disposable. Insulation, not conductive. Softness, stiffness. Fineness and expansibility. Isotropy, anisotropy Filter, breathable and impervious to water. Flexibility, stiffness. Light, loose, warm. Thin as cicada wings, thick as felt. Waterproof and moisture permeable. Ironing, stitching, molding. Flame retardant, antistatic. Water permeable, waterproof, wear-resistant and fleece resistant. Wrinkle resistance, good elasticity, high moisture absorption, water repellent.

1.Parts of nonwoven fabric production line:

Meltblown Die

The die for the extrusion of the spinneret in the melted process

.Auto Winder

Machine

The main function is to wrap the hot rolled fabric into a certain volume."

Slitter&Cutter

The main function for a large package of cloth cutting according to customer specifications, to meet the customer's length, width, volume weight requirements.

Air Compressor

It is the main body in the gas source device. It is the device that converts the mechanical energy of the motor into the gas pressure energy, and it is the pressure generator of the compressed air. It is used to control instruments and automation devices.

Upper Stretching

Make the tow tensioned.

Lower Stretching

Device

Make the tow even more uniform before entering the netting machine"

Chiller/

Refrigerating

Control the pressure oil temperature of oil pressure system, stabilize oil temperature and oil pressure, prolong oil use time, improve the efficiency of mechanical lubrication and reduce wear. Freeze dry air to guarantee the quality of the product.

2.SMS Nonwovens Fabric Mainly Application :

Precisely CNC center hold machinning parts beyond customer request

Exhibition show with customer

Shipping and package

After-sales service

Installation:

The seller will send 2 or 4 engineers to install, test the production line and train customers’ workers in buyers’ factory. It will take 1 month for whole installation and training.

WE FOCUS ON MANUFACTURING OF RELIABLE NONWOVEN LINES SINCE 1990!

HH Machinery is one of the leading and competitive providers of complete nonwoven line worldwide.

We mainly manufacture spunbond nonwoven lines and spunmelt (spunbond & meltblown) lines.

The HH 1.6 SMS making line is suitable to the production of nonwoven fabric by spun-laid and hot-rolled reinforcement.With PP as its main material ; color master batch, antioxidant,fire retardant as its additives to produce nonwoven fabric with different colors and different elements to fit the needs of different usages.This machine is able to produce SMS spun-melting nonwoven fabric , SS spunbonded nonwoven fabric,S spunbonded nonwoven fabric and M melt blown nonwoven fabric

Welcome vist us

HH non-woven machinery Co., Ltd. is a professional non-woven machinery manufacturing enterprise integrating non-woven production line design, installation, commissioning, technical transformation and non-woven production. The company has a group of professional engineers and technical backbone with more than 10 years of experience, specializing in the research, design and manufacture of various specifications of polypropylene (PP) spunbond production lines, including ssmms, SMS, SSS, and SS, S.