Chuzhou Huihuang Nonwoven Technology Co., Ltd. |

|

Verified Suppliers

|

|

New Condition High Speed SMMS Non Woven Fabric Textile Spinning Machine Non Woven Fabric Production Line

Introduction to the composition of the meltblown production line

1. Automatic suction device: 1 set

2. Polymer extrusion and meltblown spinning system

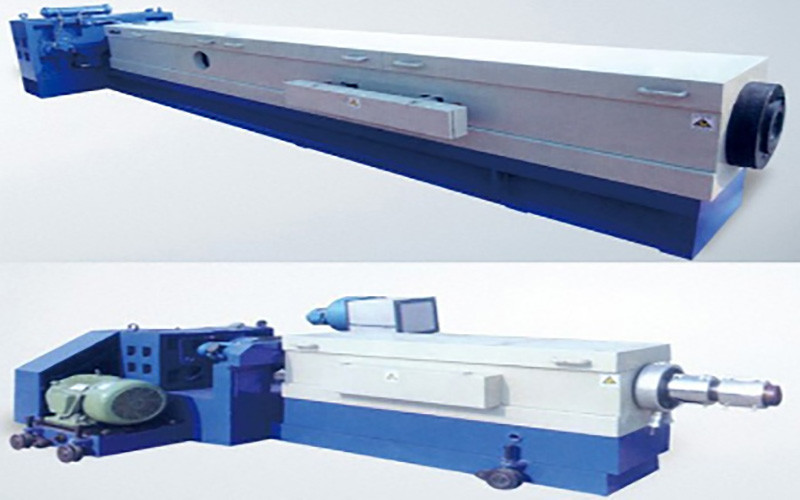

(1) Screw extruder

Model: φ135mm

Screw technical parameters:

Diameter: 90mm

Material: 38CrMoAlA

Surface treatment: nitriding polishing

(2) Filter device

Drive form: hydraulic

Structure: plate type double station hydraulic screen changer

Pressure sensor: input configuration

(3) Metering pump

Extrusion output: 50-120 kg/h

Pressure sensor: both input and output are configured

Drive power: 4.5KW

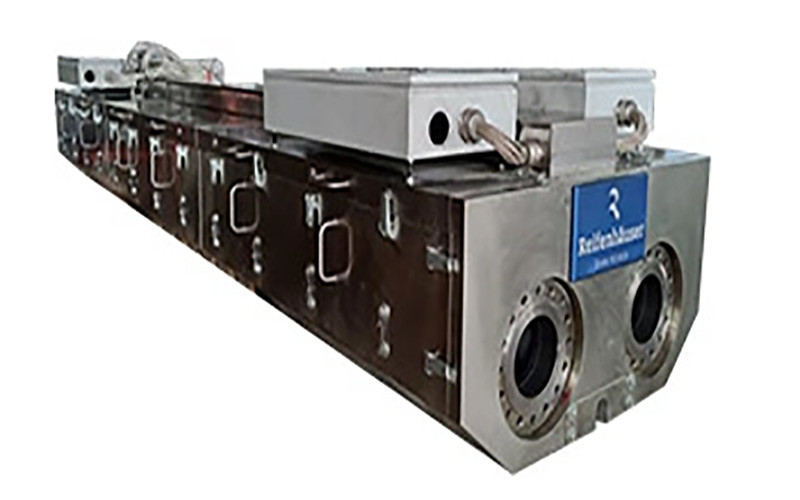

(4) Melt transportation pipeline and insulation

(5) Combination of melt blown die and spinneret

Die material: SUS630

Die size: 1600mm

Spinneret material: SUS630

Spinneret opening length: 1700mm

Spinning hole diameter: ≤0.25mm-0.35mm (customizable)

Spinning hole length-diameter ratio: 14:1

1600 SMMS Model

| Effective Width | 1600mm |

| Weight Range | 9 - 100 g / ㎡ |

| Out put daily | 7 - 12 ton |

| Machine speed | ≦ 450 m / min |

| Transformer | ≈ 1500 KVA |

| Power Consumption | 1700º - 1900 º / Ton |

| Machine Size | 55 *20 * 12 M |

| Model | Effective width | Daily capacity | Speed | Spinning system | GSM Range | Machine dimension Length*Width*Height |

| HH-1600M | 1600MM | 2000Kg | 70M/Min | Meltblown | 15-300 | 18*10*10 meter |

| HH-2400M | 2400MM | 3000Kg | 18*11*10 meter | |||

| HH-3200M | 3200MM | 4500Kg | 18*13*10 meter | |||

| HH-1600S | 1600MM | 5000Kg | 150M/Min | Spunbond (S) | 9-250 | 18*8*12 meter |

| HH-2400S | 2400MM | 7000Kg | 18*10*12 meter | |||

| HH-3200S | 3200MM | 10000Kg | 18*15*12 meter | |||

| HH-1600SS | 1600MM | 9000Kg | 350M/Min | Spunbond (SS) | 8-150 | 45*15*12 meter |

| HH-2400SS | 2400MM | 13000Kg | 45*18*12 meter | |||

| HH-3200SS | 3200MM | 16000Kg | 45*20*12 meter | |||

| HH-1600SSS | 1600MM | 12000Kg | 550M/Min | Spunbond (SSS) | 9-120 | 50*15*12 meter |

| HH-2400SSS | 2400MM | 16000Kg | 50*18*12 meter | |||

| HH-3200SSS | 3200MM | 24000Kg | 50*20*12 meter |

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

Working process

Mainly componet

| Aperture (1pc) | 90 300 kg / h |

| The screw L/D of the main extruder | 30:1 |

| The screw L/D of the ancillary extruder | 15:1 |

| Maximum temperature | 300 ℃ |

| Max. Output | 200 kg / h |

| Heating zone | 8 tod |

| Perforated length | 3,350 mm |

| HPI | 40 |

| Number of holes | 5,276 |

| 1 Set L/D | 10 |

| Capillary diameter | 0.3mm |

| Capillary length | 3,600mm |

Spinning box ,is one of most import parts of the non-woven fabric manufacturing machine. PP material through the spinning box is spun into countless strands of silk .

Advanced CNC tools

Exhibition show

Packing and delievery

FAQ

1. Q:How long will your engineer reach our factory?

A:Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc.Prepared)

2. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine installation experience.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 800CNY one day per person.

4. Q:How many days it will take for the intallation?

A: It will take around 45 days, depends on the machine type.

5. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.