Chuzhou HH Non Woven Technology CO.,LTD |

|

Verified Suppliers

|

low investment smmss smms sms ss sss for medical sanitary napkins diapers Meltblown Fabric Production Line

Product category:

1)SMMS Composite medical Non-Woven Fabric

2)SMS Composite nonwoven fabric

3)SS Spunbonded nonwoven fabric

4)S Spunbonded nonwoven fabric

5) M Melt blown nonwoven fabric

Basic gram weight:SMS:9-100g/㎡ SMS:9-100g/㎡ S:10-150g/㎡

Effective Width | Weight Range | Output per day | Machine speed | Tranformer | Power consumption | Machine Size | |

1.6M | 9-100G/M2 | 7-12Ton | ≦450m/min | ≈1500KVA | 1700º-1900º/Ton | 55M*20M*12M | |

HHM-2.4SMMS | 2.4M | 9-100G/M2 | 10-18Ton | ≦450m/min | ≈1600KVA | 1700º-1900º/Ton | 55M*23M*12M |

HHM-3.2SMMS | 3.2M | 9-100G/M2 | 14-24Ton | ≦450m/min | ≈2200KVA | 1700º-1900º/Ton | 55M*25M*12M |

HHM-4.0SMMS | 4.0M | 9-100G/M2 | 17-30Ton | ≦450m/min | ≈2500KVA | 1700º-1900º/Ton | 55M*28M*12M |

HHM-4.8SMMS | 4.8M | 9-100G/M2 | 23-36Ton | ≦450m/min | ≈200+630KVA | 1700º-1900º/Ton | 55M*31M*12M |

HHM-SSMMS Five-Beam spunmelt nonwoven fabric making machine/line | |||||

Effective Width(mm) | Raw Materials | GSM Range (g/sq.m) | Max.Speed (Tons/year) | Annual Capacity (Tons/year) | Daily Capacity (Tons/Day) |

2400 |

Polypropylene(PP) | 9-80 | 600 | 8400 | 23 |

3200 | 11400 | 31 | |||

4200 | 14600 | 40 | |||

The whole line can CUSOMIZED as your needs . | |||||

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

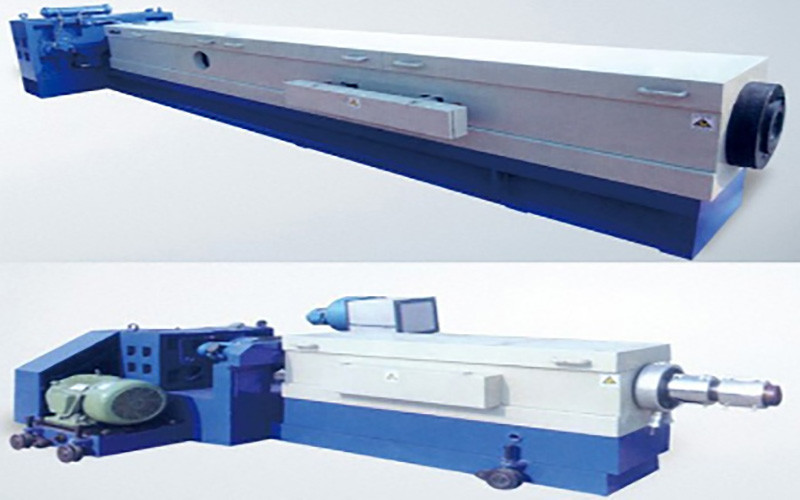

key component

Name:Main Extruder

Brand:HHM

Original:China

Diameter:Φ135mm for 1.6m,Φ170mm for 3.2m,

Max speed: 75r/min for 1.6m , 85r/min for 3.2m

Motor:90kw for 1.6m , 132kw for 3.2m

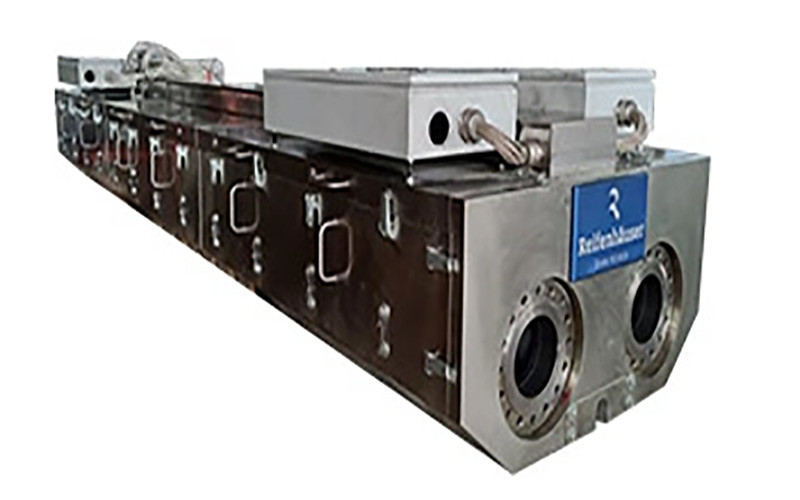

Name:Filter

Brand:HHM

Original: China

Type: Hydraulic or Candle filter

Filter precision: 45μm~60μm

Fitration area: 2.5 m2for 1.6m,3.5 m2 for 3.2m

Heat source : heat-transfer oil , circular heating

Name: Spinning Box

Orifice number:11019 for 1.6m , 17651 for 3.2m

Orifice diameter:Φ0.45mm

L/D=4:1

Max temperature:300℃

Fuction : for spining the PP flament.

Name:Metering Pump

Brand:HHM

Original:China

Supply volume:200cc for 1.6m, 200ccx2 for 3.2m

Rotate speed:5~35r/min

Max Pressure:35MPa

Temperature:≤330℃

Fuction: meter PP melt liquid

working process

Machine image

Packing and deliever

Machine Nude packing , wooden case is optional , case packing , electric parts carton box or wooden case packaged , other machines nue packaging wrapping with PE film keep cargo safe.

Our service

1. We provide pre-sales, sales and after sales service, especially

one year of free maintenance warranty.

2. If there are problems with the machine parts, customer can take

pictures and send to us by email to explain the situation, we will

help to solve

it on line or by email as soon as possible.

3. If there are big problems of the machine caused by wrong

operation, we will arrange professional engineer to solve the

problem in customer's

factory, but all the cost including visa, air fare and

accommodations must be paid by customer.