Chuzhou HH Non Woven Technology CO.,LTD |

|

Verified Suppliers

|

|

reliable electroststacic electrect water electret treatment Meltblown fabric production line

HHM 1600 Meltblown

| Effective Width | 1600mm |

| Weight Range | 15-300 g / ㎡ |

| Out put day | 2-3 ton |

| Machine speed | 10-70 m/ min |

| Transformer | ≈600 KVA |

| Power consumption | 3000º - 3500º / ton |

| Machine Size | 18 *10 *10 M |

Technical Parameters

| Model | HHM-1.6m | HHM-2.4M | HHM-3.2M |

| Effective Width | 1.6 M | 2.4 M | 3.2 M |

| Weight Range | 18-300 G/㎡ | 18-300 G/㎡ | 18-300 G/㎡ |

| Out put day | 2-3 Ton | 3-4 Ton | 4.5-5 Ton |

| Machine Speed | ≦70 m/min | ≦70 m/min | ≦70 m/min |

| Power Consumption | 3000º-3500º/Ton | 3000º-3500º/Ton | 3000º-3500º/Ton |

| Machine Size(L*W*H) | 18M*10M*10M | 18M*11M*10M | 18M*13M*10M |

Meltblown Making Machine Series

| Model | Product Width (mm) | GSM Range ( g / ㎡ ) | Capacity (kg /day ) | Melt blown (BFE&PFE) |

| HHM- 1600 | 1600 | 15 - 300 | 200 - 300 | BFE 99+ PFE 95+ |

| HHM - 2400 | 2400 | 300 - 400 | ||

| HHM - 3200 | 3200 | 450 - 500 |

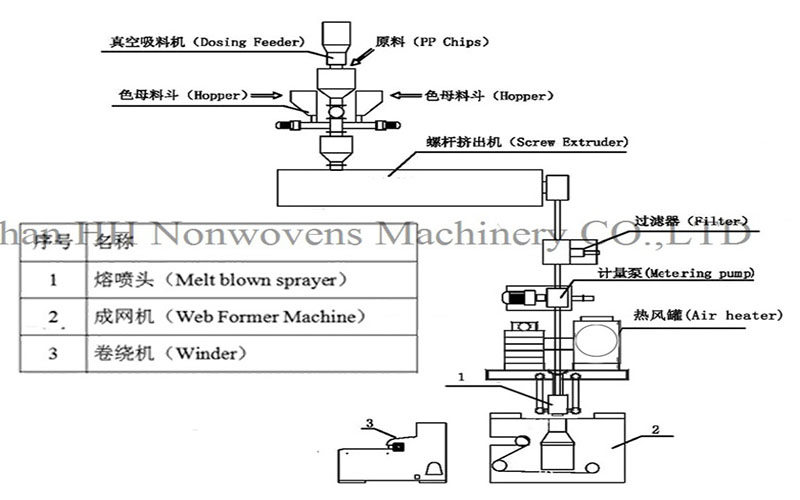

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

Meltblown non-woven fabric production line components:

Screw extruder---->filter---->metering pump---->heating system---->melt blown box (Kasen)---->netting machine---- >Rewind

High precisely CNC center

Exhibition Show

Packing & shipping

Electrical parts small parts each numbered put in carton or wooden box , large scale machine will nude wrarping with PE film fixed in container keep cargo safe .

Our Service

1.Pre-sale Service

Employees have a special sense of responsibility and excellent

teamwork spirit, so the machine adopts unique and outstanding

components, which meet the highest standards of the nonwoven

industry.

With the support of modern technology, to provide all customers

with the best solution machinery Claim.

2.After-sales Service

Our customer service can answer inquiries.

We only believe that: the best machine with innovative ideas and

high-quality after-sales service: "will meet your special

requirements."