TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

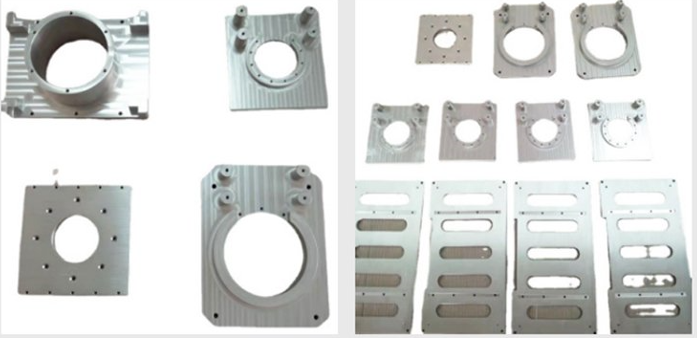

Aluminum Alloy New Energy Industry CNC Machining Parts Non-Standard Customization

What are precision machined parts?

Precision machined parts often require intricate features and require precise specifications.

These parts may include threads, holes, grooves, or tapers that must provide an exact fit with other components.

| Name | Precision CNC machining parts |

| Processing | CNC turning, CNC milling, CNC machining, Laser cutting, Grinding, EDM wire cutting,3D printing |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium: GradeF1-F5 | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| Tolerance | 0.001~0.01mm 100% QC quality inspection before delivery, can provide quality inspection form |

| Drawing Accepted | Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF, or Samples |

| Lead Time | 1-2 weeks for samples, 3-4 weeks for mass production |

| Quality Assurance | ISO9001/14000:2015 Certified.SGS |

| Payment Terms | Trade Assurance, TT/ PayPal/ WestUnion |

What Are Precision Machined Metal Parts?

Precision machined parts often require intricate features and require precise specifications.

These parts may include threads, holes, grooves, or tapers that must provide an exact fit with other components.

Precision machining is typically used to produce metal parts that require precision for the product to function properly.

For example, the components that make up an automobile engine require precise specifications for optimal performance.

There is less room for error, requiring machinists to use specialized equipment for a closer tolerance. By using computer

numerically controlled machines (CNC machines), lathes, and presses, our team manufactures a wide range of intricate

metal parts that require keen attention to detail.

The Precision Machining Process

The precision machining process often starts with an initial sketch, which is rendered using computer-aided design

(CAD) software. Engineers use CAD software such as AutoCAD to create a 3D diagram of a hand-drawn sketch.

Machinists may then enter the design into computer-aided manufacturing (CAM) programs or CNC machines. Computers

automate the removal of material to produce precise parts.

Precision machining processes allow for greater accuracy. Each cut is completed by a machine that receives instructions from

the computer software.

The machines can carry out precise cuts with limited margins of error. This results in increased repeatability. You can continue

to produce thousands of the same parts with identical specifications and tolerances down to 0.01-0.05mm.