Eternal Bliss Alloy Casting & Forging Co.,LTD. |

|

Quality Level: As per National Standard & International Standards.

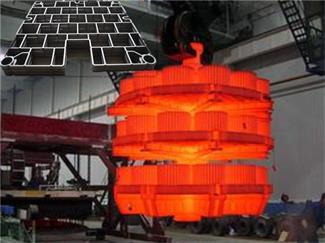

1. We can make High Temperature Material Trays Fixture with Lost Wax Process & EPC process & Sand

Cast Process.

2. We can supply finished High Temperature Material Trays Fixture with heat-treatment and machining process.

3. We can produce heat steel castings as per GB/T 20878,DIN 17440,DIN 17224, AISI,ASTM,JIS SUH35,NF A35-

572/584,BS970,BS1449,ISO 683/13.

Production Process:Lost Wax Process & EPC process & Sand Process, including machining process.

Material Grade:

Composition (%) | C | Si | Mn | Cr | Ni | S | P |

1.4823 GX40CrNiSi27-4 | 0.35~0.50 | 1.0~2.5 | ≦1.50 | 25.0-28.0 | 3.5-5.5 | ≦0.03 | ≦ 0.035 |

1.4825 GX25CrNiSi18-9 | 0.15-0.30 | 1.0~2.5 | ≦1.50 | 17.0-19.0 | 8.0-10.0 | ≦0.03 | ≦ 0.035 |

1.4826 GX40CrNiSi22-9 | 0.30-0.50 | 1.0~2.5 | ≦1.50 | 21.0-23.0 | 9.0-11.0 | ≦0.03 | ≦ 0.035 |

1.4832 GX25CrNiSi20-14 | 0.15-0.30 | 1.0~2.5 | ≦1.50 | 19.0-21.0 | 13.0-15.0 | ≦0.03 | ≦ 0.035 |

1.4837 GX40CrNiSi25-12 | 0.30-0.50 | 1.0~2.5 | ≦1.50 | 24.0-26.0 | 11.0-14.0 | ≦0.03 | ≦ 0.035 |

1.4848 GX40CrNiSi25-20 | 0.30-0.50 | 1.0~2.5 | ≦1.50 | 24.0-26.0 | 19.0-21.0 | ≦0.03 | ≦ 0.035 |

1.4865 GX40CrNiSi38-18 | 0.30-0.50 | 1.0~2.5 | ≦1.50 | 17.0-19.0 | 36.0-39.0 | ≦0.03 | ≦ 0.035 |

1.4857 GX40CrNiSi35-25 | 0.30-0.50 | 1.0~2.5 | ≦1.50 | 24.0-26.0 | 34.0-36.0 | ≦0.03 | ≦ 0.035 |

1.4855 GX30CrNiSiNb24-24 | 0.30-0.40 | 0.5-2.0 | ≦1.50 | 23.0-25.0 | 23.0-25.0 | ≦0.03 | ≦ 0.035 |

1.4849 GX40CrNiSiNb38-18 | 0.30-0.50 | 1.0~2.5 | ≦1.50 | 17.0-19.0 | 36.0-39.0 | ≦0.03 | ≦ 0.035 |

1.4852 GX40CrNiSiNb35-25 | 0.35-0.45 | 1.0~2.5 | ≦1.50 | 24.0-26.0 | 33.0-35.0 | ≦0.03 | ≦ 0.035 |

| G-CoCr28 | 0.10-0.20 | 1.0~2.5 | ≦1.50 | 27.0-30.0 | - | ≦0.03 | ≦ 0.035 |

| G-CoCr28W | 0.35-0.50 | 0.5-2.0 | ≦1.50 | 27.0-30.0 | 47.0-50.0 | ≦0.03 | ≦ 0.035 |

Production Process

Step 1: Getting orders.

Step 2: Process design by technical department

Step 3: Purchase of raw materials and pattern making &checking

Step 4: Inspection of raw materials

Step 5: Melting by middle-frequency induction furnaces

Step 6: Ladle analysis by Spectrometer

Step 7: De-oxidization, slag-removal, tapping

Step 8: Pouring

Step 9: Openning & fettling

Step 10: Surface & dimensional check

Step 11: Heat treatment

Step 12: Inspection of physical property (UT test,MT test, hardness,impact value µstructure)

Step 13: Packing

Step 14: Shipping