Suzhou Xunshi New Material Co., Ltd |

|

Verified Suppliers

|

|

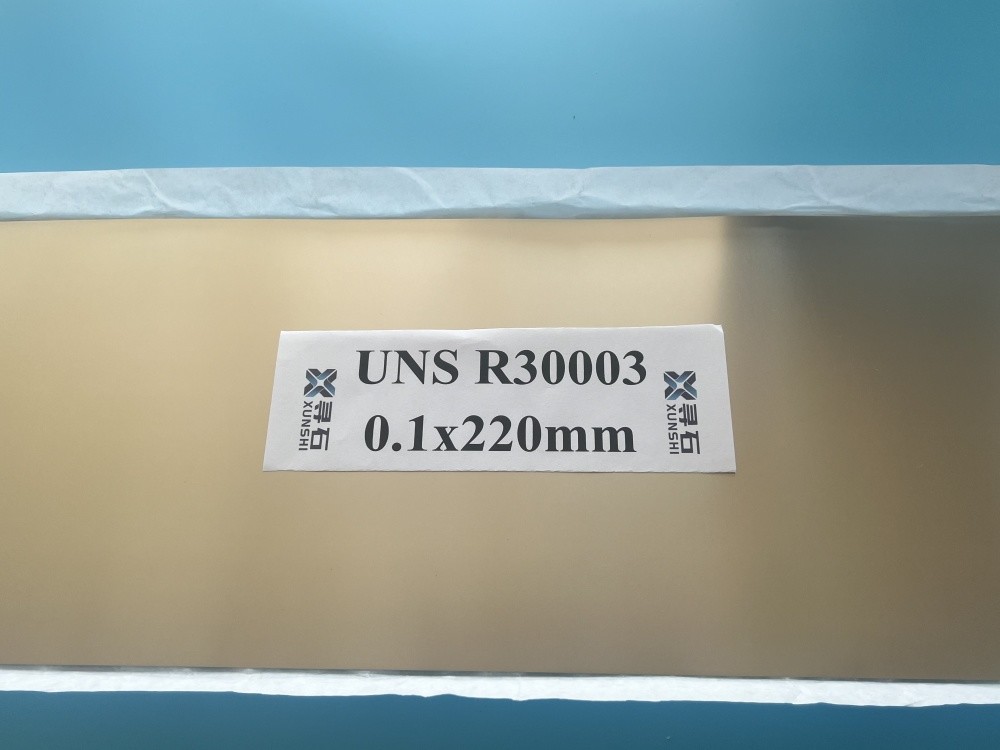

New Arrival: Super-thin R30003/R30008 Cold Rolled Foil for sensor and damper, minimum thickness 0.01mm

R30003/R30008 is is an austenitic alloy strengthened by cold work and capable of additional hardening by aging at a moderate temperature (around 500°C). In the fully hardened condition, its elastic modulus is around 210 000 MPa, with UTS levels up to 2500 MPa on cold rolled strip. In addition to its very high yield strength, PHYNOX offers a range of physical, chemical and technological properties that make it appropriate for a wide variety of applications.

Xunshi is glad to announce that we could offer cold rolled R30003 foil of thickness down to 0.01mm and width 70mm. The foil could be used in application like sensor and damper.

Phynox cold rolled strip is one of our main products and we have rich experience in the area. Our Phynox(2.4711) products are widely used in surgical implant industry, mobile phone, diaphragm valve, oil field monitor, spring seal, spring energized seal, Variseal and spring.

Size of R30003/R30008 cold rolled strip/foil available

Chemical composition(weight, %) ASTM F1058

| Grade | C | Mn | Si | P | S | Co | Cr | Ni | Mo | Be | Fe |

| R30003 | 0.15 max | 1.5-2.5 | 1.2 max | 0.015 max | 0.015 max | 39.0-41.0 | 19.0-21.0 | 14.0-16.0 | 6.0-8.0 | 0.10 max | Rem |

| R30008 | 0.15 max | 1.0-2.0 | 1.2 max | 0.015 max | 0.015 max | 39.0-42.0 | 18.5-21.5 | 15.0-18.0 | 6.5-7.5 | 0.001 max | REm |

Applications

Features

Forms of supply

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.