CHANGSHA SANCHANG PUMP CO., LTD. |

|

The DY series Multistage Ring Section Centrifugal Water Pump is a utility-grade, high-pressure, ring section pump with heavy duty, segmental ring, diffuser design. Axial thrust balance device with stacked rotor construction. Suitable for boiler feed pump and high building, long distance water transferring.

End-suction pumps can be found in virtually every industrial facility and water treatment plant in the world. In addition, they are commonly used in fire protection and HVAC systems, and as pressure-boosting pumps (booster pumps) in plumbing systems for large buildings such as big-box stores, stadiums, office buildings, and shopping malls.

Any close-coupled pump, whether of the end-suction design or not, will be designed for the impeller to mount directly onto the end of the motor shaft, and for the pump casing to bolt directly to the face of the motor.

Structure Design

Horizontal, radially split, ring section pump with radial impellers, single or double flow entry, multistage. The stages are sealed against each other by O rings or by metallic sealing faces and fastened by tie bolts.

High operating reliability

* Axial thrust balancing by balance disc.

* Adaptation of pump casing to rotor deflection line.

Ease of service

* Easy maintenance of wear parts (bearings, seal elements,

balancing devices).

* Metal-to-metal sealing of casing.

Long service life

* Avoidance of cavitation erosion inside the pump through

hydraulically optimised inlet.

* Variant straight shaft design featuring increased operation

safety.

Reduced energy costs

* No pre-warming of pump required.

* More than 100 impeller/diffuser combinations with optimum

efficiencies possible.

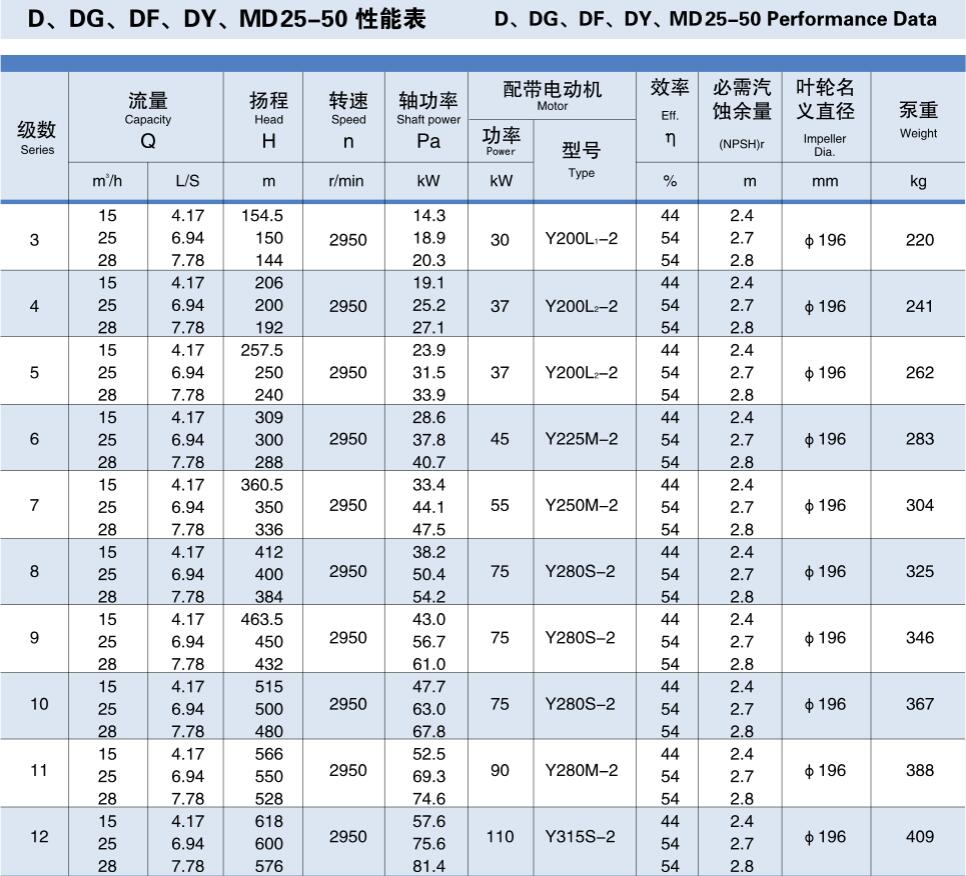

Parameters of Multistage Centrifugal Process Pump D25-50X3-12

| Flow Capacity | 15-28 m3/h | Delivery Head | 144-618 m |

| Inlet/Outlet Dia. | DN80/DN80 mm | Working Pressure | ≤ 3.45 MPa |

| Liquid Temperature | 0 - 80 ℃ | Driven By | Electric Motor / Diesel Engine |

| Seal Type | Mechanical seal / Gland packing | Liquid | Clean water or similar |

| Material of Construction | Cast Iron / Cast Steel / S.S304 / S.S316 / Duplex S.S2205 | ||

| Parts Name | Clean Water | Sewage | Hot Water | Corrosive Liquid | Oil Liquid |

| Pump Body | Cast Iron | Ductile Iron | Cast Steel/S.S304 | S.S304/S.S316/S.S2205 | S.S304/S.S316 |

| Shaft | Cast Iron | S.S420 | S.S420/42CrMo | S.S630 | S.S420/40Cr |

| Shaft Sleeve | Carbon Steel | S.S420 | S.S304 | S.S316/S.S630/S.S2205 | S.S304/S.S316 |

| Impeller | Cast Iron | Ductile Iron | Cast Steel/S.S304 | S.S304/S.S316/S.S2205 | S.S304/S.S316 |

| Wearing Ring | Cast Iron | Ductile Iron | Cast Steel/S.S304 | S.S304/S.S316/S.S2205 | S.S304/S.S316 |

| Bearing | China Make/NSK/SKF/Customized | ||||

| Seals | Mechanical Seals/Gland Packing Seals | ||||