Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

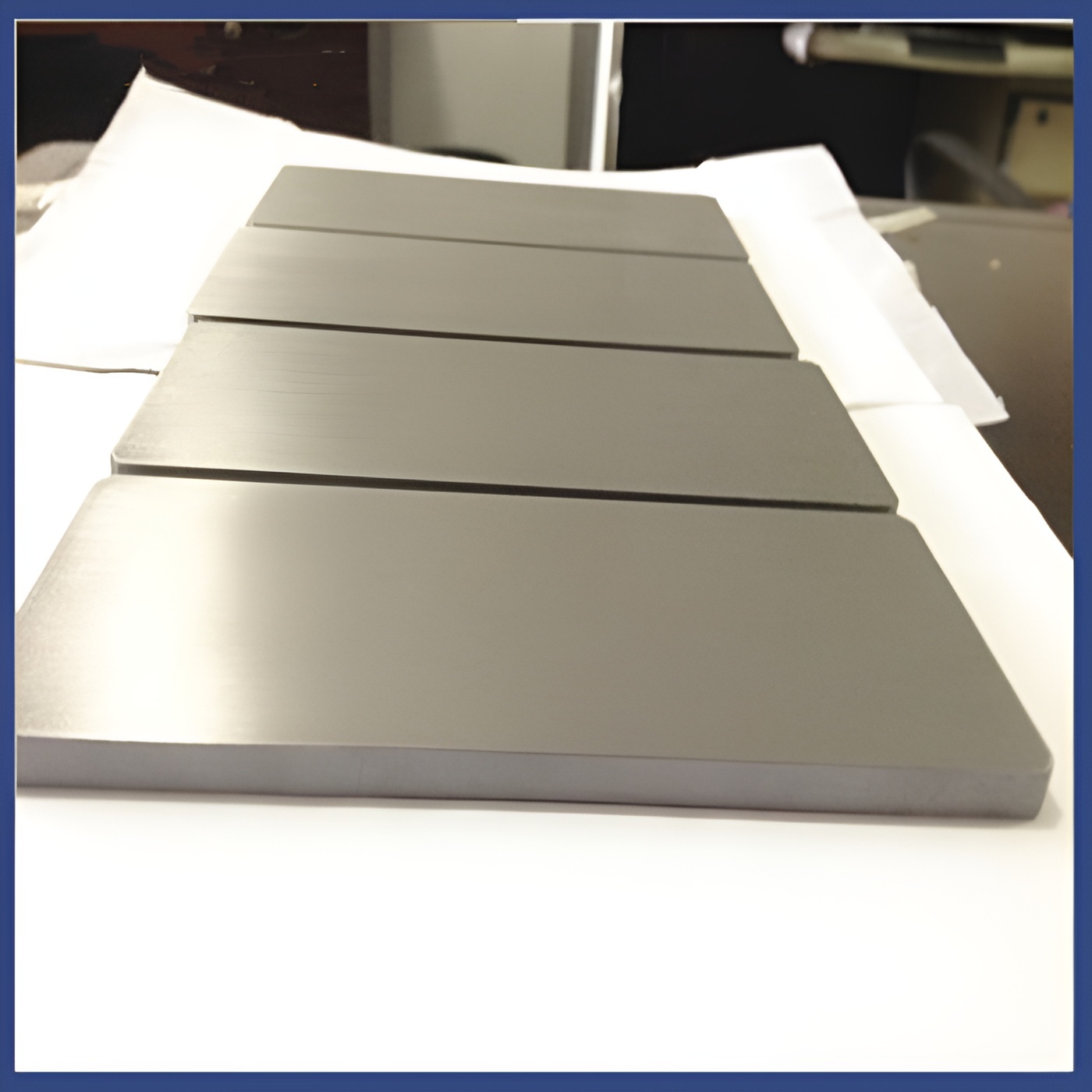

TZM Alloy Plate Prepared By Powder Metallurgy

1. Description Of TZM Alloy Plate Prepared By Powder Metallurgy:

The best molybdenum alloy is TZM. This alloy contains not less than 99.2% molybdenum, up to 99.5%, 0.50% titanium, 0.08% zirconium and Mo-Hf-C alloys strengthened by hafnium carbide particle precipitation. At temperatures above 1300°C, TZM is twice as strong as pure molybdenum. The recrystallization temperature of TZM is about 250'C higher than that of molybdenum, and it has better welding performance.

The surface of the titanium zirconium molybdenum plate (TZM plate) is dark brown, and after chemical cleaning, it is silver-gray metallic luster. According to the width and thickness provided by the user, our company can produce TZM boards with smooth and flat surface, no defects such as heavy skin, delamination, cracks, cracked edges, and inclusion of impurities. Mainly used for molybdenum furnace parts, electric vacuum devices, thermal insulation bottles, etc.

2. Size Of TZM Alloy Plate Prepared By Powder Metallurgy:

Common some size of TZM alloy plate:

| Thickness | < 0.15 mm | 0.20 mm | 0.25-0.4 mm | 0.5-2.0 mm | 2.5-3.5 mm |

| Max. Size | 150x1000 mm | 500x1500 mm | 610x3000 mm | 610x1500 mm | 500x1000 mm |

Other size can be processed as per customer's request.

3. Production Of TZM Alloy Plate Prepared By Powder Metallurgy:

1). Mix 0.45% Ti, 0.08% Zr, 0.01% C and graphite powder with Mo for 6 hours.

2). The mixed powder is pressed and formed under the pressure of

150MPa by cold isostatic pressing.

3). Under the protection of hydrogen, place the pressed slab in a

sintering furnace at 2100°C for 4 hours, and then sinter into a TZM

alloy slab.

4). The slab with a thickness of 30mm is hot rolled at 1350°C, so

that the thickness of the slab becomes 4.5mm, and the deformation

amount is 83%. Then at 700~750℃, the slab is rolled to 1.2mm, and

its total deformation is 95%.

5). Anneal at 900℃ to relieve stress, then longitudinally roll to

0.7mm at 600~700℃.

6). After annealing at 850°C to eliminate stress, longitudinal cold

rolling is performed at 200~300°C to obtain a 0.5mm alloy plate, in

which the total deformation is 98%.

4. Chemical Of TZM Alloy Plate Prepared By Powder Metallurgy:

| Quantitative analysis | |||||||||||||||||||

| Element | Si | Mn | Ni | Cu | V | Zr | O | P | Fe | Mg | |||||||||

| Concentration(%) | 0.002 | 0.0009 | 0.0008 | 0.0018 | 0.013 | 0.086 | 0.32 | 0.001 | 0.0011 | 0.0015 | |||||||||

| Element | Al | Ti | Ca | C | N | ||||||||||||||

| Concentration(%) | 0.001 | 0.5 | <0.001 | 0.012 | 0.0022 | ||||||||||||||

| Purity(Metallic Base) Mo≥99.06%(TZM) | |||||||||||||||||||

Related Products:

Mo plate Mo electrode Mo crucible Mo boat

Do you want to know more about our products?