Shenzhen Johnhalm PDTec.,Ltd |

|

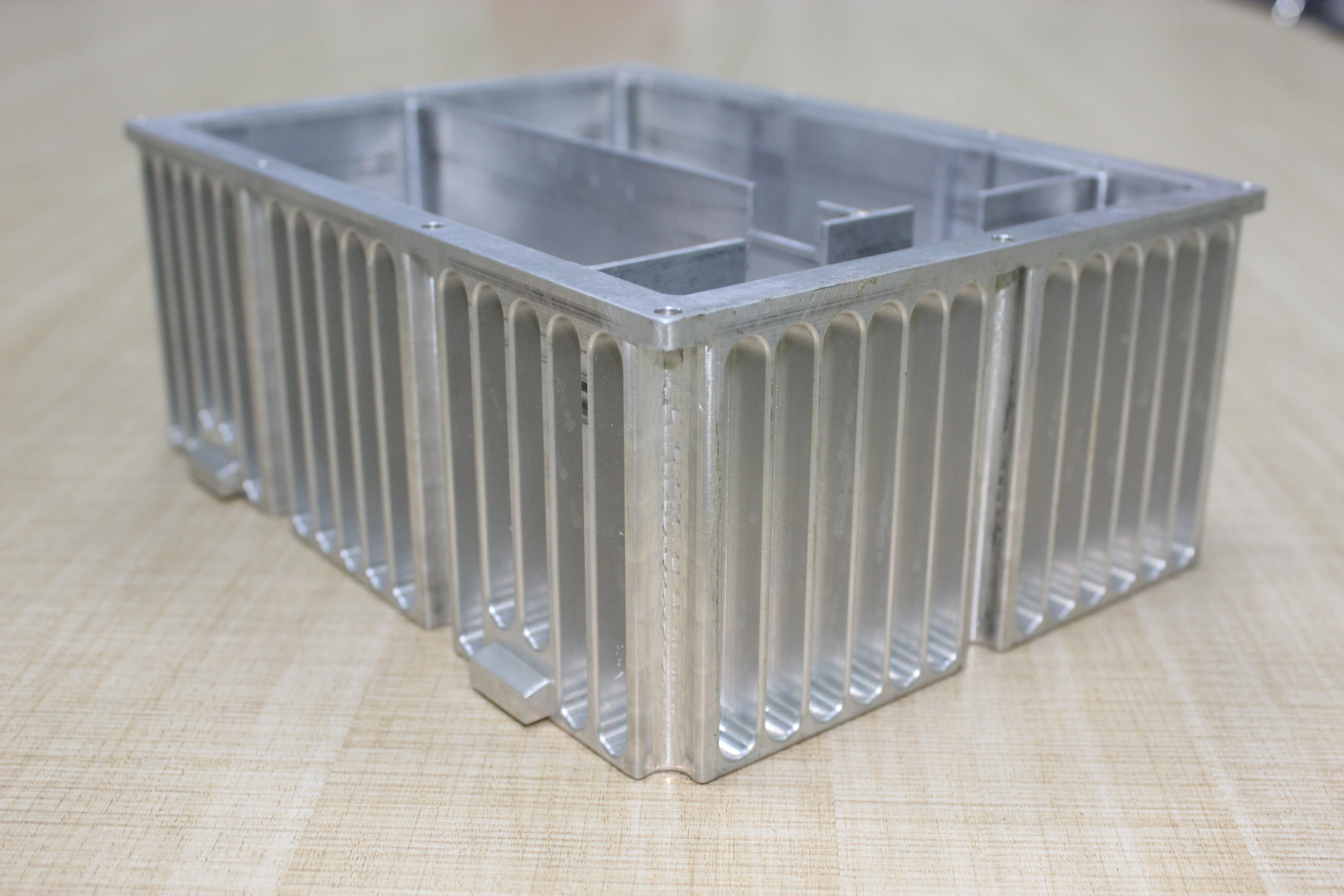

Small Batch CNC Milling Production For Car Automobile Controller Housing

Shenzhen Jiaheng Mould Manufacturer and Shenzhen Johnhalm PDTec.,ltd is a professional manufacturer extablished in 2005. We have been delicated to the mold making industry for more than 16 years. We have accumulated rich experience and build up a strong steady engineering and manufacturing team, which supports us to become a reliable supplier as well as the strategic partner of customers worldside.

| Product Description | OEM Aluminum Die Casting Par |

| Material | Aluminium: ADC-1, ADC-12, A380, DIN 1706:231, DIN 1706:260, AlSi9Cu3 ,ALSi12cu |

| Zinc alloy: Zamak2 3 4 5 7 | |

| Cartographic Software | Pro-e / Solid work / UG / Auto CAD / CATIA |

| Mold Making | Independent mold design and development capability, mold flow analysis software, slow wire cutting, EDM, drilling center, machining center, high-speed engraving machine, 200T mold closing machine, three coordinates, etc. |

| Processing Equipment | Full automatic servo die casting machine 160 ton/180 ton/280 ton/500 ton/800 ton, 2 shot blasting machines, 2 grinding machines, 3 drilling centers, 9 CNC lathes, 2 processing centers, ultrasonic cleaning line, full automatic spraying line, |

| PRODUCT PROCESS | Customer drawings or samples -- Mold fabrication -- Die casting -- Trimming -- Deburring -- Shot blasting -- Machining center (drilling center) -- Grinding -- Ultrasonic cleaning -- Surface treatment -- Assembly -- Inspection (testing) -- Packaging -- Shipment |

| Surface Treatment | The surface treatment of our products are: spray, paint, anodic oxidation, electrophoresis, plating Ni, Sn, Cu, Ag, Zi, etc. |

| Quality Inspection | X-flaw detector, spectrometer, tensile machine, salt tester, finish meter, pneumatic meter, profilometer, three coordinates, water tightness tester. |

| Appication | Security components (such as support, bottom seat, outer cover, outdoor monitoring shell, etc.) |

| Automobile parts: (such as: pressure reducing valve, globe valve, pedal body, pressure limiting valve, shock absorber bracket, radiator shell, on-board panel, etc.) | |

| Cleaning machine parts (such as: high pressure pump valve body, bracket, drive bracket, drive wheel, aluminum fasteners, etc.) | |

| LED lamp components (e.g. Lampshade, panel, housing, etc.) | |

| Electric tools and motor parts (such as motor housing, front and rear covers, etc.) | |

| Intelligent door lock (such as various handles, front decoration components, rear decoration components, lock cover) | |

| All kinds of mechanical parts (such as pump shell, Hinges, junction box, etc.), fitness equipment (such as: aluminum bracket). Electronic equipment of all kinds of radiators, all kinds of junction box. Garden machinery accessories (such as: chainsaw gearbox) and so on. |

Products Range

| Automotive | Auto interior plastic case, Auto inner parts, Bumper, Door plate, Lamp shell, Instrument panel, auto connectors , Electrical switch; Car gear, Complete sets of motorcycle parts; |

| Electronic | Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards, USB Connector, USB housing, Mobile phone plastic part, remote control, key-press; |

| Mechanical | Motor support plastic part, Pump plastic part, mower plastic parts; |

| Household | Fashion cup, Juice cup, Some small plastic parts; |

| Home appliance | TV front cover, TV rear cover, Display cover, Air-conditioner or Refrigerators plastic parts, Washing machine part; |

| Medical | Hollow fiber dialyzer, Deaf-aid parts, Medical instrument body plastic parts, Blood-pressure meter parts, Blood-pressure meter, Stapler. |

Services

1. Project Evaluation

2. Product Design

3. Electronic Design and Engineering

4. Mechanical Design and Engineering

5. Prototype Design and Engineering

6. Design for Manufacturing

7. Manufacturing Coordination

8. Mould design

9. Manufacturing

10. Second processing

11. Assembly and etc.

12. One-stop services for plastic parts.

Product

Package and Transport

FAQ

1. How can I get the quotation?

Please send us the drawing, quantity, weight and material of the

product.

2. What kind of file can you read?

PDF, IGS, DWG, STEP,etc...

3. What is your way of packing?

Normally we pack goods according to customers' requirement.

For reference: wrapping paper, carton box, wooden case, pallet.

4. When can I get the samples and your main order time?

For samples: 25-35 days after start to make mold.

For order:30 days, the accurate time depends on product.

5. What's your payment term?

1)Tooling cost 50% deposit and 50% after T1 samples approved.

2) Parts cost Net30

3) Payment Method: Wire