Shenzhen Biest Precision Technology Co., Ltd. |

|

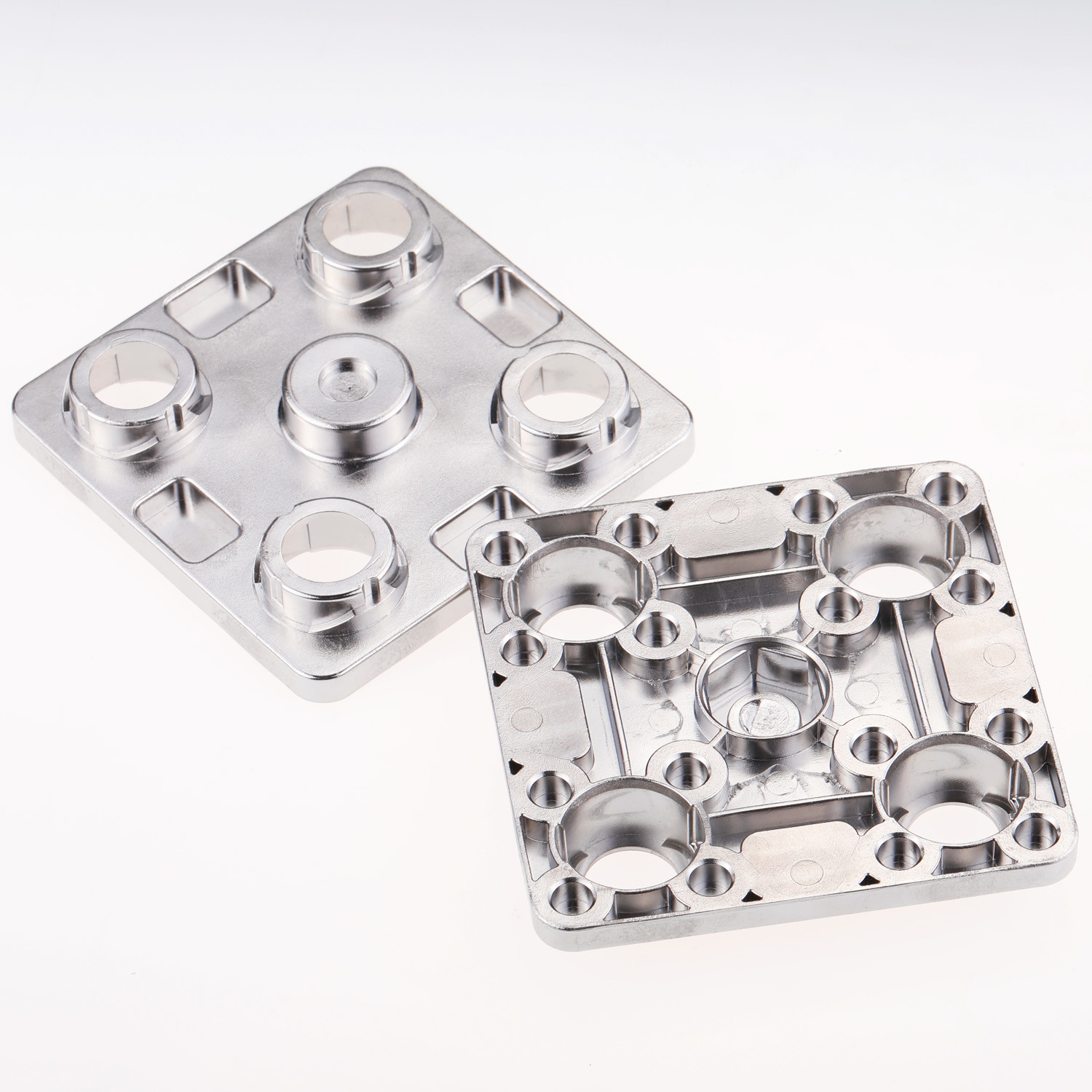

Middle Frame For Mobile Phone.

Stainless Steel material powder metallurgy metal injection molding sintered parts MIM products.

How to work with us:

1. Send us 3D drawing (STEP/IGS/SolidWorks format etc. )

2. Specify the requirements (quantity, material, and surface finish requirements etc) to us via

email.

| Manufacturing range | MIM Metal Injection Molding |

| color | could be customized |

| Applicable Material | stainless steel/titanium/brass/copper etc. |

| Our advantage | 1. Rich experience in metal injection molding field. 2. Small order accepted for the beginning 3. New material develop capability. 4. Top quality guaranteed by skilled workers, managing system and status of facilities. 5.100% quality inspection before delivery |

| Surface finsih | Natural machined color/anodized finish/ coating / Passivation / PVD finish/nickel white/brush/heat treatment/fine glass beads/grounding/tumbled finish etc. |

| Payment Terms | 50% deposit before production and 50% balance before arranging to

ship |