Luoyang Zhongtai Industrial Co., Ltd. |

|

Verified Suppliers

|

|

Big Kiln Girth Gear Ring Mill Girth Gear And Mill Pinion Gear

1. Technical requirements of large gear ring for mill girth gear

(1) The surface pretreatment before quenching is normalized, and the hardness should be HB210~250; Mechanical properties are strength limit Rb690MPa, yield limit Rs490MPa, elongation d511%, area reduction w25%, impact toughness value Ak30J. Tooth induction hardening, hardness of HRC50~55; Effective hardening depth 3~5mm.

(2) Ultrasonic inspection shall be carried out on the whole, and the internal quality shall meet the secondary requirements stipulated in GB7233-87 standard; Gear tooth and transition fillet magnetic particle inspection, quality should meet GB/T9444-88 standard requirements.

(3) Uncast rounded corners R5~R10.

(4) Chamfering of both ends and edges along the tooth width. Big gear ring by two half gear ring connected with high strength bolts into a whole gear ring, the joint surface must be in the center of the tooth bottom.

Large Kiln / Mill Girth Gear

2. Product parameters of big ring for mill girth gear

| The big gear ring | ⑴GS42CrMo4 alloy cast steel (enterprise standard) HB 220 ~ 240 The half structure, Y type plate. (3) oblique tooth. (4) Reasonable sealing and alignment structure. | ⑴ Outside refining of molten steel furnace (argon blowing and R-H vacuum treatment). (2) The special cold mold sand hanging technology is adopted to ensure the density of casting and tooth. (3) Normalizing treatment (proprietary technology) to ensure tooth surface hardness. (4) After rough hobbing, release aging, repair the joint surface, and then fine rolling ⑸ homemade hob precision hobbing. | ⑴ Mechanical properties and chemical composition of casting blank (internal control standard). (2)The ultrasonic crack detection after rough machining. ⑶ half finishing, finishing ultrasonic inspection and magnetic particle inspection. (4) Tooth surface magnetic particle inspection, hardness inspection. ⑸ Check tolerance of tooth profile. ⑹ No-load test of general assembly before delivery, check the meshing accuracy of large and small gears. |

Large Kiln / Mill Girth Gear

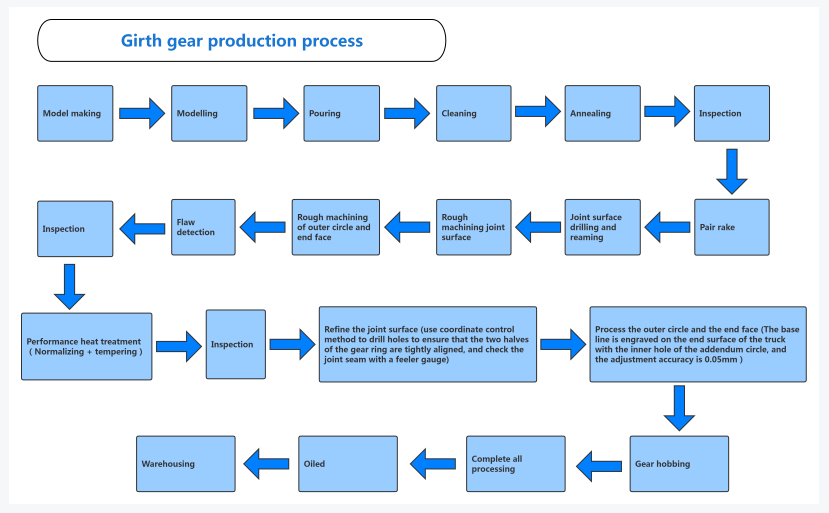

3. Manufacturing process of big tooth ring for mill girth gear

(1) Blank

The steel casting blank is provided by the heavy casting and forging Plant of CITIC Heavy Industry Machinery Co., LTD. It is implemented in accordance with gb11352-89 standard. Molding, smelting, pouring, box beating, cleaning and dressing castings according to casting process requirements; During the inspection and acceptance, the cast steel blank shall be checked according to the drawings and technical requirements, and the process shall be put down after passing the acceptance according to JB/T6402-92 standard.

(2) Rough machining

Draw lines according to the requirements of the drawings and set aside processing allowance, alignment, connection, processing inner and outer circle, milling joint surface, drilling and other processes.

(3) Agent injury

Ultrasonic inspection shall be carried out on the whole, and the internal quality shall meet the secondary requirements of GB7233-87 standard.

(4) Normalizing pretreatment

The half ring is normalized and tempered in pairs to provide good microstructure for subsequent surface quenching. And according to the requirements of the drawings to check the deformation of half gear ring after heat treatment.

Large Kiln / Mill Girth Gear

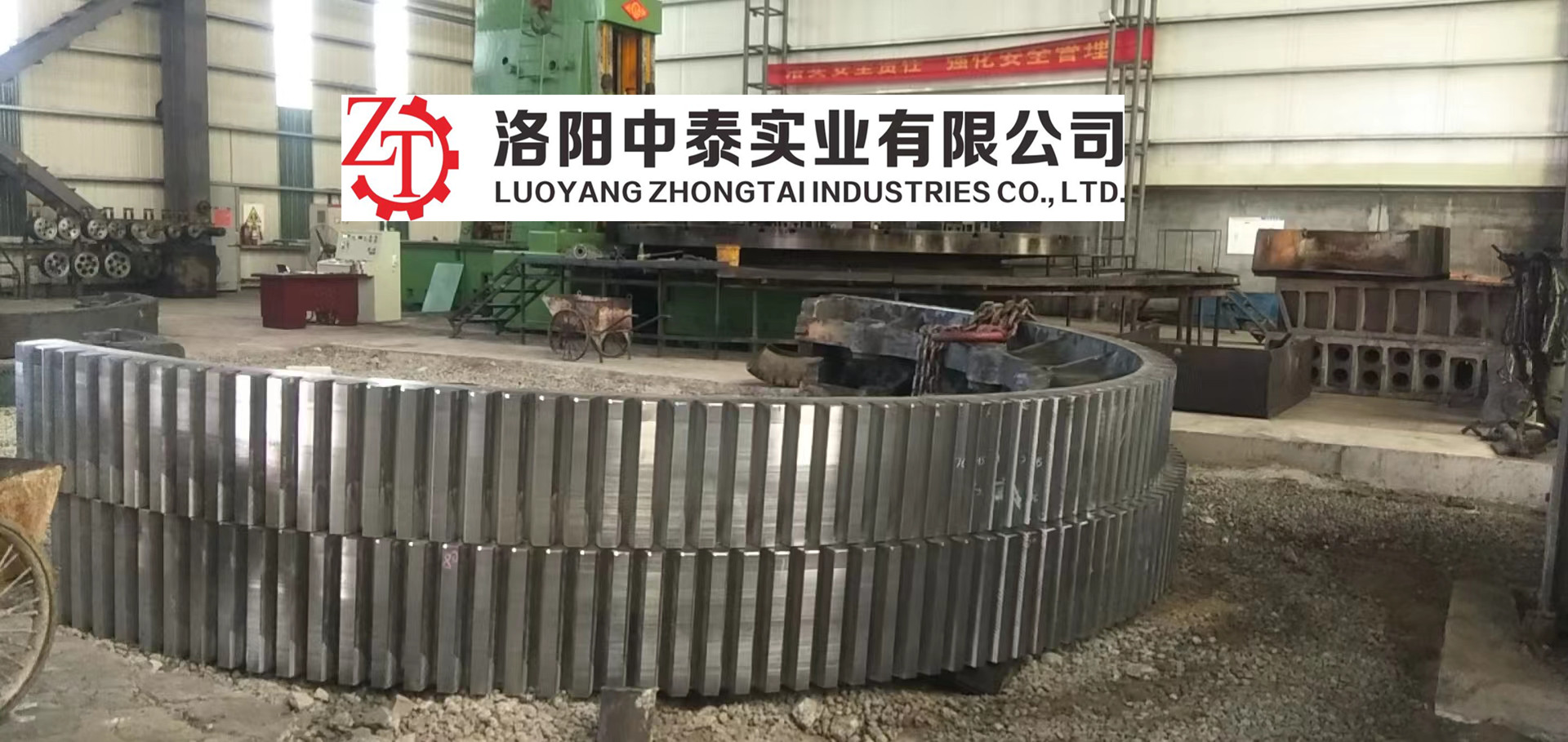

4. Case introduction of large ring gear

(1) The gear ring with the largest modulus in China -- The gear ring is manufactured by Zhongshi Heavy Machinery Co., LTD., with the diameter of the outer circle of 6.39 meters and the hobbing modulus of the gear reaching 45, which is the highest in China.

China's largest diameter ring gear - On August 7th, 2011, the largest diameter ring gear designed and manufactured by CITIC Heavy Industries was being finished by the Reassembly Department and was about to roll off the assembly line. The ring, which is nearly 11 meters in diameter and weighs more than 70 tons and has a level 7 precision, was made by Citic Heavy Industries for China National Gold Group Corp.

Through testing, the precision of all parameters of the gear ring meet the design and process requirements. The successful manufacture of the ring gear is another masterpiece in the process of Zhongxin Heavy Industry to build a leading domestic and internationally famous modern enterprise, which lays a solid foundation for Zhongxin Heavy Industry to manufacture a larger diameter ring gear in the next step.

Large Kiln / Mill Girth Gear