Luoyang Zhongtai Industrial Co., Ltd. |

|

Verified Suppliers

|

|

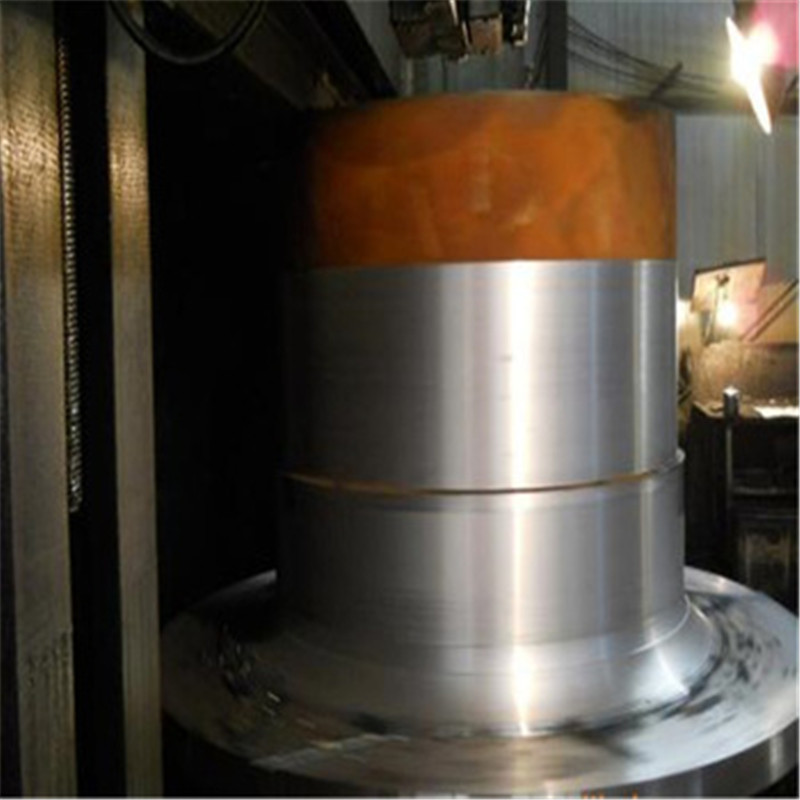

| Product name | Hollow shaft |

| Material | ZG45,ZG42CrMo,35CrMo,ect |

| Structure | Casting or forging |

| Process | Lathing, milling,grinding |

| Max.diameter | 2000mm |

| Max.length | 8000mm |

| Max.tolerance | ±0.3 |

| Type | According to drawings |

| Certification | SGS |

Ball mill Hollow shaft Advantages: 1. high quality steel 2. large R fillet 3. high strength bolts and cylinder connection 4. molten steel refining furnace (blowing argon and R-H vacuum treatment) 5. using special sand, strictly control the pouring temperature and casting speed 6. bolster bearing processing, to ensure that the coaxial degree of end mouth and roughness 7. casting rough mechanical properties and chemical composition (internal control standard) 8. ultrasonic examination after rough machining 9. ultrasonic detection and magnetic particle inspection after finishing |