Guangxi Henkry Machinery Co., Ltd |

|

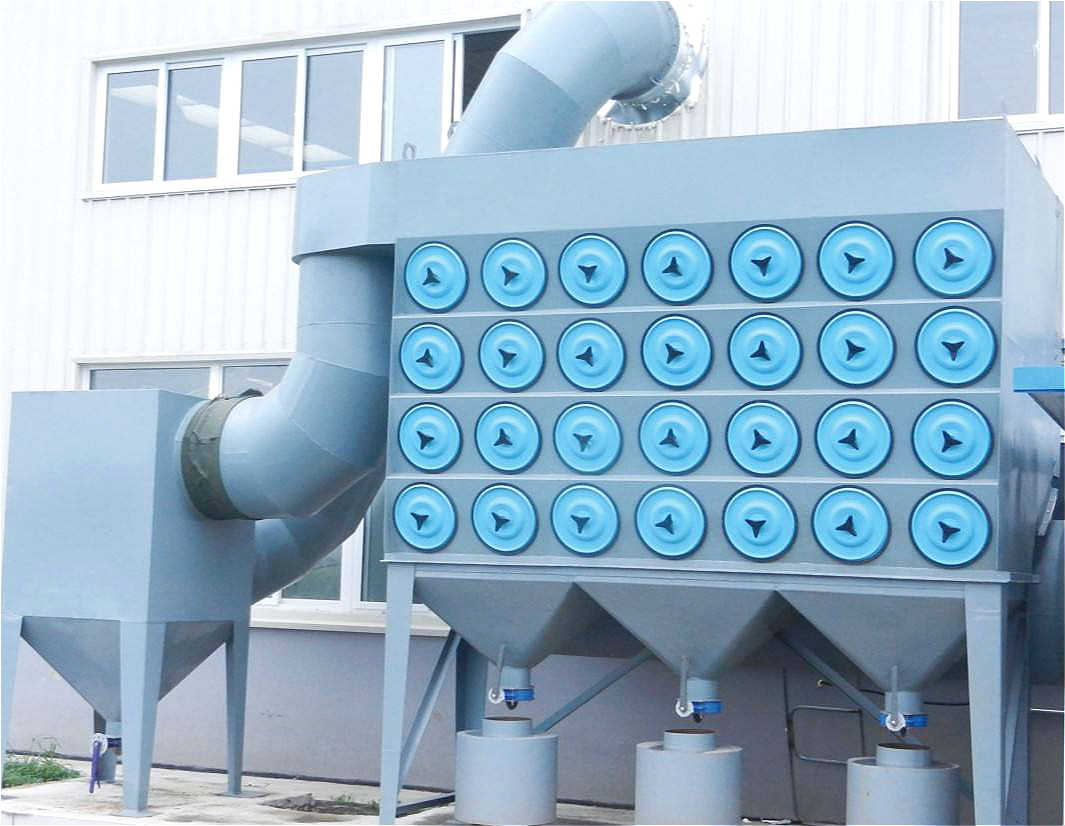

Tail-Made Filter Cartridge Dust Collector For Various Industries:

Introduction & Working Principle of Filter Cartridge Dust Collector:

The filter cartridge dust collector is operated under negative pressure. The dust-containing air enters the tank through the air inlet; Under the action of the negative pressure in the folding filter cartridge, the air enters the cylinder through the filter material outside the cylinder, and then enters the clean air chamber, and finally the clean gas is discharged from the air outlet. When the dust accumulates on the surface of the filter material, the resistance is getting larger and larger (can also be set by time), the pulse valve is opened, the compressed air is directly sprayed into the center of the filter cartridge, and the filter cartridge is sequentially pulsed to remove the dust, and the dust on the surface of the filter cartridge is purged.

Advantages of Filter Cartridge Dust Collector:

1. Excellent filter material ensures dust removal efficiency of up

to 99.99% for 1 micron.

2. It can be used as dust collector and dust removal system for

various working conditions.

3. Simple structure.

4. Small size and saving floor space.

5. Easy maintenance.

6. Long service life.

7. The unit type combined structure makes the filter area, the

treatment air volume and the external dimensions can be widely and

flexibly selected, and has strong practicability.

8. Use imported or domestic assembled filter cartridges to ensure

filtration efficiency of up to 99.99% for submicron particles

9. Using the unique sinking design principle, using gravity and

top-down airflow flow pattern, avoiding secondary pollutionto

filter material

10. The perfect combination of high efficiency filter cartridge and

sinking dust collector greatly reduces the size and footprint of

the dust collector

11. Low running resistance, low energy consumption and operating

costs. Usually the initial resistance is 25mm water column, normal

operation resistance is 50-75mm water column

12. Horizontal filter cartridge design, easy to repair and update

filter cartridges, faster, safer and greatly reduce downtime

13. Adopt advanced automatic compressed air pulse cleaning method

to make the life of the filter cartridge longer and ensure the

continuous operation of the dust collector.

Application of Filter Cartridge Dust Collector:

1. The application rate in tobacco, medicine, machinery processing,

food, metallurgy, chemical, hardware processing, building

materials, light industry, electronics, pharmaceutical and other

industries is very high.

2. Suitable for plasma, laser cutting, welding fume and other

working conditions in large steel structures, shipbuilding,

automobile manufacturing, metal processing and other industries.

3. Tungsten powder, molybdenum powder and other precious

non-ferrous metals, recycling of pharmaceutical dust.