Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

36mm Micro Linear Stepper Motor 12V High Thrust Through Shaft Screw Motor

VSM36L-048S-0254-113.2 is a through shaft type stepping motor with

guide screw. When the rotor operates clockwise or counterclockwise,

the top of the screw rod needs to be fixed, and the guide screw

will move forward or backward.

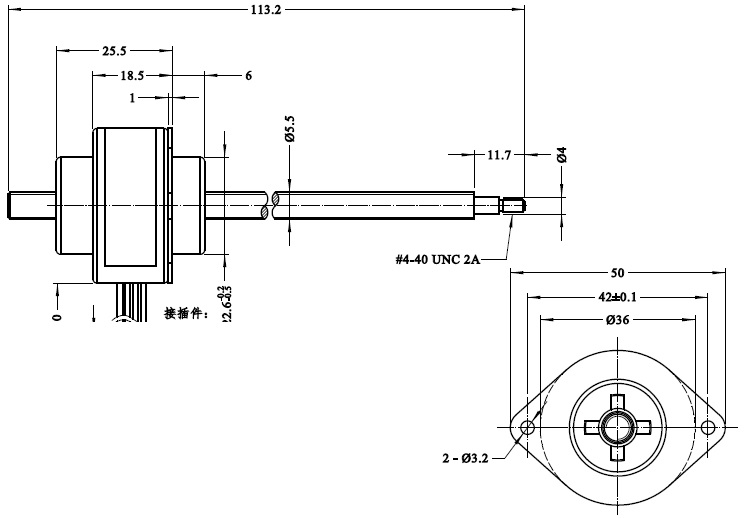

The stepping angle of the stepping motor is 7.5 degrees, and the

lead spacing is 1.22mm. When the stepper motor rotates for one

step, the lead moves 0.0254mm, and the length of the screw rod of

the motor can be customized according to customer needs

The product converts the rotation of the motor into linear motion

through the relative motion of the inner rotor and the screw. It is

mainly used in valve control, automatic buttons, medical equipment,

textile machinery, robots and other related fields.

At the same time, the external wiring can be connected or output

from the outlet box according to customer requirements

Our team has more than 10 years of experience in stepping motor

design, development and production, so we can achieve product

development and auxiliary design according to the special needs of

customers!

| PRODUCT NAME | PM36 5v Linear stepper motor |

| MODEL | VSM36L-048S-0254-113.2 |

| POWER | 5.6W |

| VOLTAGE | 5V |

| PHASE CURRENT | 560mA |

| PHASE RESISTANCE | 9(土10%) Ohm / 20C |

| PHASE INDUCTANCE | 11.5(±20%) mH I lkHz |

| STEP ANGLE | 7.5° |

| SCREW LEAD | 1.22 |

| STEP TRAVEL | 0.0254 |

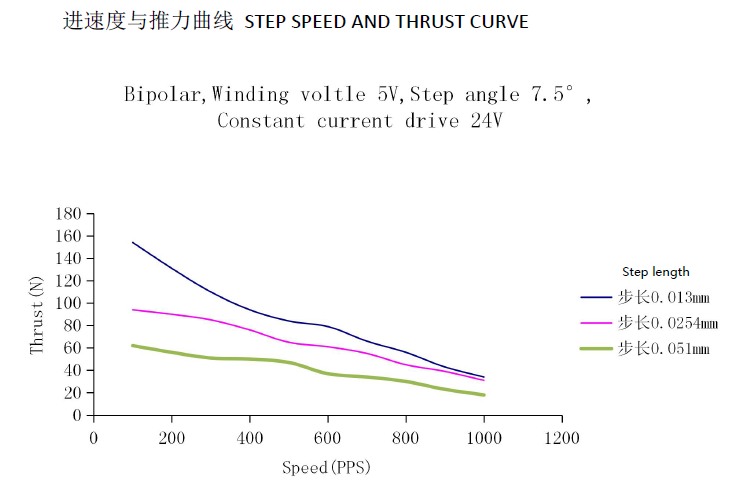

| LINEAR FORCE | 70N/300PPS |

| SCREW LENGTH | 113.2mm |

| OEM & ODM SERVICE | AVAILABLE |

The motor can customize the normal screw stroke,

Connectors and outlet boxes can be customized according to customer

requirements

The screw rod can also customize the nut

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of

customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by

express

Mass production, motors are packed in corrugated cartons with

transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets

On samples and air shipping, we use Fedex/TNT/UPS/DHL. (5~12 days for express service)

For sea shipping, we use our shipping agent, and ship from Shanghai

port. (45~70 days for sea shipping)

1.Stepper motor pulse signal deceleration:

Stepper motor rotation speed, is based on the change of the input

pulse signal to change. In theory, give the driver a pulse, the

stepper motor rotates a step angle (subdivision for a subdivision

step angle). In practice, if the pulse signal changes too quickly,

the stepper motor due to the internal damping effect of the reverse

electric potential, the magnetic response between the rotor and

stator will not follow the change in the electrical signal, will

lead to blocking and lost steps.

2.Stepper motor how to use the curve exponential control speed?

Exponential curve, in the software programming, first calculated

time constants stored in the computer memory, work pointing to the

selection. Usually, the acceleration and deceleration time to

complete the stepper motor is 300ms or more. If you use too short

acceleration and deceleration time, for the vast majority of

stepper motors, it will be difficult to achieve high-speed rotation

of stepper motors.