Jiangyin Dingbo Technology CO., Ltd. |

|

Touch Screen PLC Control Rack Upright Roll Forming Machine For Hydraulic Station Power 5.5kw With Thickness 0.8-2.0mm

Main features

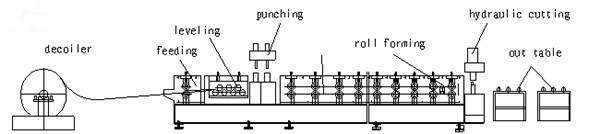

This shelf rack roll forming machine is consisted with auto-de-coiler, guide frame, lever/feeding section, continuous bottom hole punching section, forming section, positioning and cutting section, collection table and electrical control system etc.All kinds of roll forming machine can customized, so just send your profile drawing to me.

Working flow

Technical parameters

| No. | Main parameter of rack upright roll forming machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | As customer need |

| 3 | Thickness of the plate | 0.8-2.0mm |

| 4 | De-coiler | Manual one, can load 5 tons raw material |

| 5 | Rollers for forming | 18 rows |

| 6 | Diameter of the roller | 52mm |

| 7 | Rolling material | Carbon Steel 45# |

| 8 | Main motor power | 4kw |

| 9 | Productivity | 10-15m/min |

| 10 | Cutting method | Hydraulic mould cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kw |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | PLC control , Siemens |

| 15 | Side panel of machine | 14mm |

| 16 | Main structure of the machine | 300 H steel |

| 17 | Dimensions | 7.5*1.0*1.5m |

| 18 | Voltage | 380V 50Hz 3phases(changeable as needs) |

Machine components

| No. | Name | Unit | Qty |

| 1 | Manual decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1 |

Machine pics

Profile drawing

Production process

Main features

a.The structure is simple and the appearance of the machine is

beautiful because we adopt the shape-steel structure and process as

a whole after welding. it has the ability of strong loading and

stable operation when running the machine.

b.All the components of machine are from brand-famous enterprise so

that they ensure the machine normal function very effectively.

c.We adopt the automatic length-fixed forming and cutting to

guarantee the length to be precise and the finished product clear

without deforming .

d.It is very easy to install the equipment and suitable for

producing in the factory.

e. The machine has features of low noise and high efficiency.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to

produce.

2.Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine overseas to customers’ workshop

if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in hurry, we can

make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and

profile drawing you provide. Our engineers can offer the best

professional solution to our worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7.How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi Dong station),

half an hour.

8.What's the warranty period?

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipments at the Buyer’s

Installation site.

9.Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246