Jiangyin Dingbo Technology CO., Ltd. |

|

380V 50Hz Glazed Tile Roll Forming Machine With Hydraulic Pressing And Cutting

Product Descriptions

Roof Panel roll forming Machine is a metal panel roll forming machine for continuous rolling and cold-forming on steel sheet. Through decoiling, continuous rolling and cold-forming, the coil sheets are automatically cut to the size and specification required. The stacking of finished panel can be also done automatically. The Joint-hidden Roofing Forming Machine adopts PLC control, AC frequency and speed adjusting technology to realize continuous work automatically. The roll former of self-locked is energy-saving and roll forming machinery according to customers' requirements.

Product Parameters

| Items | Specifications | |

| Material of coil | Materialc | color steel |

| Material Width | 1000mm | |

| Material Thickness | 0.3-0.5mm | |

| Manual Uncoiler | 5 tons | |

Forming system | Rolling Speed | 3-5m/min |

| Roller Stations | 10 Stations | |

| Roller Material | 45#steel 0.03-0.05mm chromed | |

| Shaft Material | 45#steel | |

| Shaft DIA | D70mm | |

| Main Motor Power | 5.5kw | |

| Side Plate | Wall plate | |

| Way of Drive | By chain | |

| Cutting system | Hydraulic punching and cutting Power | 3kw |

| Material of blade | Cr12Mov | |

| Tolerance | +1.5mm |

Version to design

Working Flow

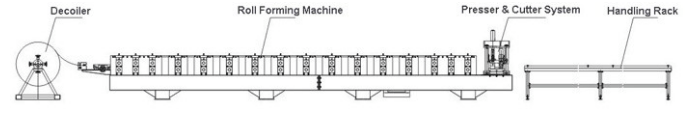

Decoiler — Guiding device — Forming system — Hydraulic Cutting— Run out table

Main Components

| No. | Name | Qty |

| 1 | Hydraulic Decoiler | 1 |

| 2 | Main roll forming machine | 1 |

| 3 | PLC Control box | 1 |

| 4 | Hydraulic station | 1 |

| 5 | Output table | 2 |

Machine Pictures

Application:

Roof Panel roll forming Machine is a metal panel roll forming machine for continuous rolling and cold-forming on steel sheet. Through decoiling, continuous rolling and cold-forming, the coil sheets are automatically cut to the size and specification required. The stacking of finished panel can be also done automatically. The Joint-hidden Roofing Forming Machine adopts PLC control, AC frequency and speed adjusting technology to realize continuous work automatically. The roll former of self-locked is energy-saving and roll forming machinery according to customers' requirements.

FAQ:

1. Q: What's the warranty period? (24hours online)

12 months warranty period, starting from the date of the successful installation and commissioning of the equipment at the Buyer’s Installation site. During which all parts damaged because of quality problem will be changed for free.

2. Q: Do you have installation and commissioning service?

A.If buyers come to our factory to inspect, the training to install and operate is provided face to face. If not, manual and video is provided to show how to install and operate.

B. If buyer need we will send technician to buyer site to do installation and commissioning and training.

C.installation and commissioning cost: One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100/per day and visa fee, air tickets fee, accommodation and food, necessary communication, etc.

(Normally ,It takes about a week to install )

3. Q: What’s your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

4. Q: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time

5. Q: You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

6. Q: Do you provide customized machine?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

7. Q: How to visit your factory?

We are in jiangyin city,belongs to Jiangsu province,

near Shanghai. If you arrive at Shanghai Airport,we can pick you up

It is 160 kilometers from Pudong Airport, about 3 hours.

It's 110 kilometers from Hongqiao airport, about 2 hours; It's 125 kilometers from downtown Shanghai about two and a half hours.

It is very convenient.Please let me know if you have booked the tickets

so that I can prepare and book a hotel for you,we will arrange for car to pick you up.

By high speed train from Shanghai to East Wuxi (Wuxi Dong station), half an hour.

8. Q: How to place order ?

Inquiry---confirm the profile drawings and technical specification and price----confirm the PI---arrange the deposit or L/C---start production-- do inspection--- Shipment

9. What are your terms of payment ?

First payment: 30 % by T/T, second payment: 70% by T/T, after the successful inspection at seller’s workshop, and before delivery.