Jiangyin Dingbo Technology CO., Ltd. |

|

Trapezoidal Roof Panel Roll Forming Machine for Color Steel or Aluminum Sheet

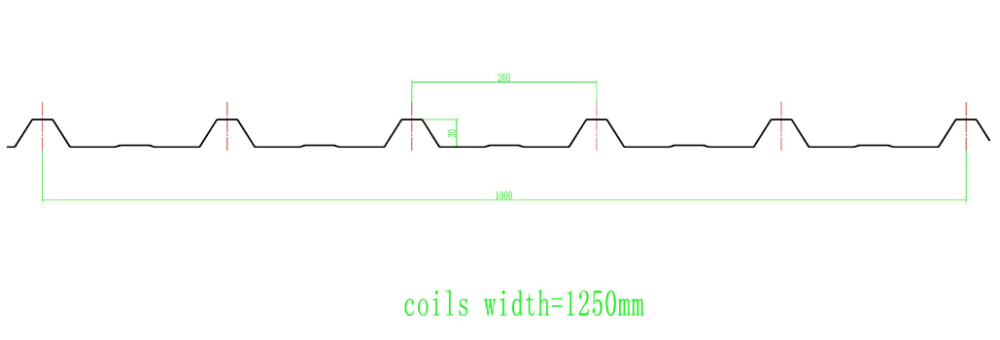

Profile Drawing

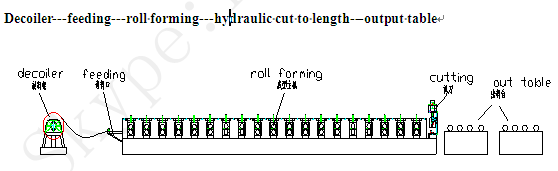

Working Flow

A.Main Data

1)Main motor power: 5.5kw

2)Drive: Chain

3)Main shaft dia: 76mm material: 45 forge steel and quenched

4)Roller material: 45# forge steel ,chrome coated 0.05mm

5)Roll station: 20 steps

6)Type of forming machine: wall panel

7)Raw material: GI steel 0.3-0.8mm

8)Width of feeding material: 1250mm

9)Working speed: 10-15m/min(Exclude cutting time)

10)Length Tolerance: ±1.5mm

11)Weight of machine: about 5ton

12)Size of machine: About 7500×1800×1500mm L x W x H

13)cof machine: yellow and blue

14)Coder: Omron, made in Japan

15)Control: PLC Panasonic, made in Japan. 380V 50HZ(Also depend on

customer requirement)

16)Computer operating panel: touching screen

17)Cutting: Hydraulic cutting

18)Auto cutting when reach the set length. Hydraulic power: 3KW

19)Blade material: Cr12,quenched 55°-58°

20)Working pressure:16mpa

B. Manual Decoiler

1)Capacity: 5ton

2)Feeding width: MAX 1250mm

3)Expanding range: 480-520mm

C. Passive Output Table

1) Valid length: MAX 4m

2) Capacity: 3ton

3) Max loading height: 100mm

4) Transport: by roller passively

Character of Main Structure:

a) The structure is simple and the appearance of the machine is

beautiful because we adopt the shape-steel structure and most of

the connectors are screw which make the machine flexible and

stronger.

b) All the components of machine are from brand-famous enterprise

so that they ensure the machine normal function very effectively.

c) We adopt the automatic length-fixed forming and cutting to

guarantee the length to be precise and the finished product clear

without deforming .

d) It is very easy to install the equipment and suitable for

producing in the factory.

e) Low noise with high efficiency.

Photos for Refer: