Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

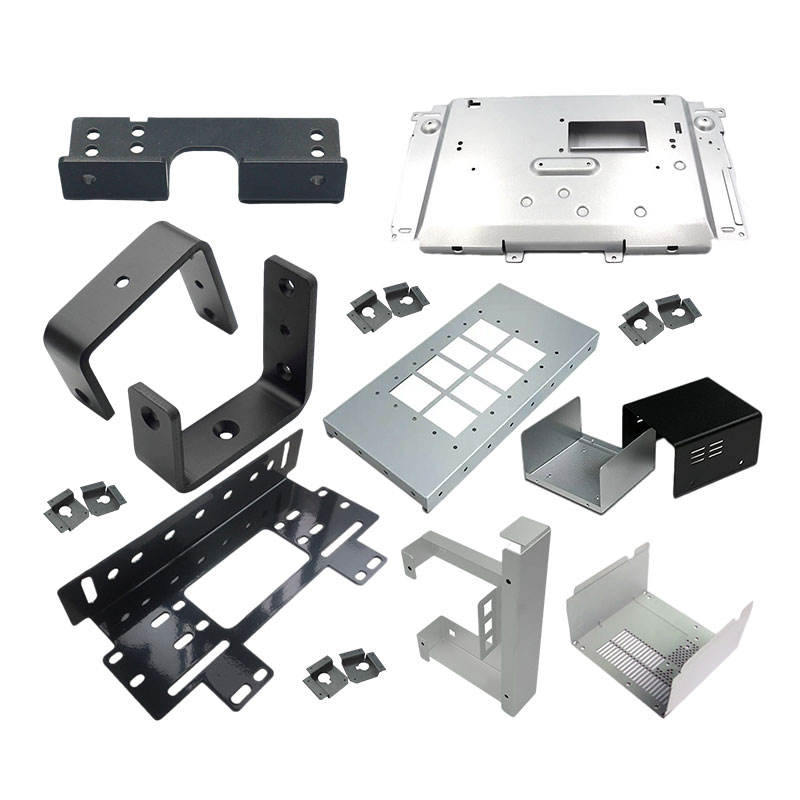

Metal Machining CNC Express Shipping for Fast and Accurate Machining Mechanical parts processing

Our Mechanical Parts Processing product is a premium offering in the domain of precision manufacturing, catering to a diverse array of industries including Appliance, Auto, Building, and Capital equipment among others. With a focus on delivering high-quality components, we utilize state-of-the-art CNC Machining technology to ensure that each part meets the stringent requirements of our clients. The incorporation of CNC technology not only enhances the precision of the mechanical parts but also significantly reduces production time, enabling us to offer a competitive edge in both quality and efficiency.

The surface of each component undergoes a meticulous Anodizing treatment, which provides a durable and corrosion-resistant finish. This surface treatment is crucial for parts that are exposed to harsh environments or are required to have a high degree of wear resistance. The anodized layer not only enhances the aesthetic appeal of the parts but also extends their service life, ensuring long-term performance and reliability.

Our processing capabilities are versatile and can accommodate a wide range of materials. This versatility, combined with our CNC Machining expertise, allows us to produce complex geometries and high-precision parts with exceptional accuracy and repeatability. The precision of CNC Machining ensures that every part conforms to the exact specifications provided by our clients, which is vital for the seamless integration of our components into their final products.

Understanding the urgency of production demands, we are committed to providing a swift Lead Time of 7-15 Days. Our efficient production processes and meticulous planning enable us to deliver your orders within this timeframe, ensuring that your project timelines are met without compromising on quality. Whether it is a prototype or a full-scale production run, we are equipped to handle your requirements with the utmost efficiency.

We recognize that every project is unique, and as such, we offer OEM/ODM services to cater to the specific needs of our clients. Our team of skilled engineers works closely with customers to tailor solutions that meet their unique specifications and design requirements. By offering customizable options, we provide our clients with the flexibility to innovate and create products that stand out in their respective markets.

When it comes to shipping, we offer a variety of methods to suit the needs of our clients. Whether it is Express shipping for urgent requirements, Air freight for a balance between speed and cost, or Sea freight for large volume orders, we have the capabilities to ensure that your parts arrive safely and on time. Our logistics team is experienced in managing the complexities of global shipping and works diligently to provide the most efficient and cost-effective transportation solutions.

In conclusion, our Mechanical Parts Processing product, with its emphasis on CNC Machining, superior Anodizing surface treatment, and rapid turnaround times, is an ideal choice for industries looking for high-quality mechanical components. We are dedicated to exceeding the expectations of our clients in the Appliance, Auto, Building, and Capital equipment sectors, among others. Our commitment to OEM/ODM flexibility, combined with our strategic shipping options, makes us a reliable partner for all your mechanical part needs.

| Technical Parameter | Specification |

|---|---|

| Application | Industrial Machinery, Appliance, Auto, Building, Capital equipment, etc. |

| Size | Customized |

| Sample | Available Upon Request |

| Material | Metal |

| Surface Treatment | Anodizing |

| OEM/ODM | Available |

| Processing Type | CNC Machining |

| Tolerance | ±0.01mm |

| Shipping Method | Express, Air, Sea |

| Lead Time | 7-15 Days |

| Manufacturing Location | China Fujian |

Mechanical parts processing products, especially those crafted through CNC machining, are integral components in various industrial machinery applications. These products, originating from China, boast high-quality manufacturing, as evidenced by their ISO certification. They are indispensable in scenarios where precision and customization are paramount, with a remarkable tolerance of ±0.01mm, ensuring that each piece meets stringent specifications.

The application occasions for these CNC machining products are diverse, extending across multiple sectors of the industry. Given their certification and precision, they are often employed in the aerospace, automotive, and medical equipment industries, where the margin for error is minimal, and the demand for reliability and performance is at its peak. Manufacturers and engineers rely on these components for their projects, knowing that each part is produced with meticulous attention to detail, ensuring that every dimension is accurate to the design.

The minimum order quantity for these parts is set at 100, making them accessible for both small-scale operations and large industrial endeavors. They come in neutral packaging, which provides a layer of protection during transportation while maintaining a professional appearance. The delivery time is set at 30 days, which is a reasonable timeframe for customized CNC machining products. The payment terms are straightforward, with TT (Telegraphic Transfer) being the accepted method, ensuring a secure transaction.

Companies can rest assured about the supply availability, as there is a capacity to produce over 10,000 pieces every 7 days. This means that even for large orders, the wait time remains minimal, and the supply chain is not hindered. The surface treatment of these parts includes anodizing, which not only provides a sleek, aesthetic finish but also enhances corrosion resistance, making the products suitable for harsh environments and extending their operational life.

While these mechanical parts processing products come in a standard size, customization is a key attribute, enabling them to fit into complex assemblies and unique industrial machinery designs. Samples are available upon request, allowing potential buyers to assess the quality and compatibility of the parts before committing to a full order. This level of customer service is indicative of the supplier's confidence in their product and their commitment to customer satisfaction.

The versatility of these CNC machining parts makes them ideal for a wide range of applications. They are not just another component; they are the embodiment of precision engineering and manufacturing excellence. With their robustness, precision, and customizable features, these mechanical parts processing products stand as a testament to the capabilities of modern CNC machining technologies.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs per week

Lead Time: 7-15 Days

Surface Treatment: Anodizing

OEM/ODM: Available

Sample: Available Upon Request

Application: Industrial Machinery

Product Customization Services: We offer comprehensive machining cnc services to cater to the unique needs of our clients. With our advanced Cnc Machining technology, we ensure precision in Mechanical parts processing . Our team is dedicated to providing tailor-made solutions that meet and exceed expectations.

Our Product Technical Support and Services for Mechanical Parts Processing provides comprehensive assistance to ensure the smooth operation and maintenance of your products. Our team of experienced engineers is dedicated to offering expert advice, troubleshooting, and problem-solving solutions for any technical issues you may encounter with your mechanical parts processing equipment.

We offer a range of services including:

Technical guidance for installation, setup, and configuration of equipment to get your operations up and running quickly and efficiently.

Operational support to help optimize the performance of your machinery, including advice on best practices and maintenance routines.

Troubleshooting assistance to diagnose and resolve unexpected technical problems, minimizing downtime and productivity loss.

Upgrade and retrofit services to ensure your equipment stays up-to-date with the latest technological advancements and regulatory standards.

Preventive maintenance programs designed to extend the lifespan of your mechanical parts processing equipment and avoid costly repairs or replacements.

Our goal is to provide you with the support needed to maintain high-quality production standards and operational efficiency. Please refer to your product documentation for specific instructions or contact our technical support team for personalized assistance.

For our mechanical parts processing products, we ensure that each item is securely packaged to prevent any damage during transit. Our packaging process involves multiple steps to ensure the utmost protection of the products. Each mechanical part is first wrapped in a protective layer to prevent scratches or surface damage. After the initial wrapping, the parts are encased in cushioning materials, such as foam or bubble wrap, to absorb any impact during shipping.

The cushioned parts are then carefully placed into sturdy, corrugated boxes that are sized appropriately to prevent excessive movement. We use packing fillers to fill any voids within the box, ensuring that the parts remain immobile while in transit. The exterior of the box is sealed with heavy-duty packing tape to maintain the integrity of the package. For particularly delicate or high-value parts, we may use wooden crates or custom packaging solutions to provide additional security.

Once the packaging is complete, we label each package with the necessary shipping information, including handling instructions and any cautionary markings required for mechanical components. Our shipping department then selects the most reliable carrier service based on the destination, size, and weight of the package, to ensure timely and safe delivery. We provide tracking information to our customers so they can monitor the shipment's progress until it reaches its final destination.

Q1: What is the place of origin for your mechanical parts processing products?

A1: All of our mechanical parts processing products originate from China, ensuring quality and reliability with a focus on local manufacturing expertise.

Q2: Do your mechanical parts processing products come with any certification?

A2: Yes, our products come with ISO certification, which means they meet international standards for quality and safety.

Q3: What is the minimum order quantity for these products?

A3: The minimum order quantity for our mechanical parts processing products is 100 units, allowing us to serve both small and large-scale industrial needs.

Q4: How are the products packaged?

A4: Our products are packaged using Neutral Packing to ensure they are protected during shipping and handling, while also being ready for branding by distributors or end users.

Q5: What is the standard delivery time for an order?

A5: The standard delivery time for an order is approximately 30 days, which ensures we have adequate time to process, manufacture, and quality check all items before shipment.

Q6: What are the accepted payment terms for purchasing these products?

A6: We accept payment via TT (Telegraphic Transfer), which is a secure and efficient way to handle transactions for our customers.

Q7: What is your supply ability for these mechanical parts?

A7: We have a supply ability of over 10,000 pieces per week, ensuring that we can meet the demands of our customers and the market.