Jiangsu Zhongtong Weiye Special Steel Co. LTD |

|

AISI 4130 35CrMo Cold Rolled Precision Steel Tube Seamless for Precision Engineering

AISI4130 and AISI4140 are all belong to "ALLOY STEEL" material,the content of Cr and Mo is much higher than Carbon Steel material.And they have perfect performance during impact.

So they have widely use in the gear for locomotive traction,turbocharger transmission gear,pressure vessel gear,rear axle,connecting rods and spring clips with heavily loaded.

Cold Rolled High Precision Seamless Steel Pipes have bright,smooth and oil-dipped surface.So it can save energy during the maching process.

35crmo Alloy Chrome Steel Pipe Tube

| Chemical Composition(%) | Mechanical Property | |||||||||

| C | Si | Mn | S | P | Cr | Ni | Cu | Mo | Yield Strength | Tensile Strength |

| ( σs ) | ( σb ) | |||||||||

| 0.32~0.40 | 0.17~0.37 | 0.40~0.60 | ≤0.035 | ≤0.035 | 0.80~1.10 | ≤0.030 | ≤0.30 | 0.15~0.25 | ≥ 835(85) (MPa) | ≥ 985(100) |

| (MPa) | ||||||||||

| End Shape | Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer's requirements | |||||||||

| Surface | Oiled, Galvanized, Phosphate etc | |||||||||

| Treatment | ||||||||||

| Technique | Cold drawn | |||||||||

| Application | 1. Automotive and mechanical pipes | |||||||||

| 2. Petroleum cracking pipes | ||||||||||

| 3. High Pressure Boiler Pipe | ||||||||||

| 4. Low and middle pressure fluid transportation pipeline | ||||||||||

| 5. Chemical fertilizer equipment pipes | ||||||||||

| 6. Heat exchanger pipes | ||||||||||

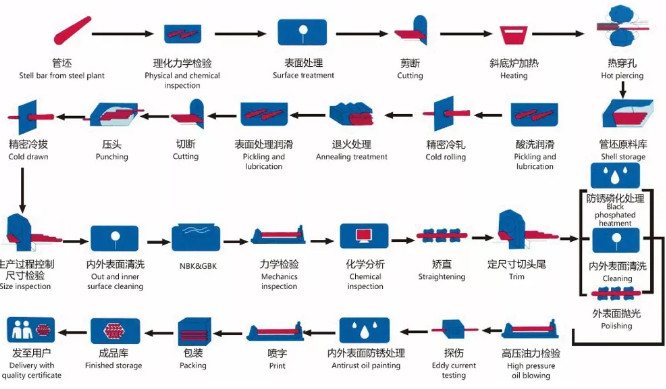

| Delivery | 1. BK (+C) | No heat treatment after last cold forming process. | ||||||||

| Conditions | 2. BKW (+LC) | After last heat treatment there is a light finishing pass (cold drawing) | ||||||||

| 3. BKS (+SR) | After the final cold forming process the tubes are stress relieve annealed. | |||||||||

| 4. GBK (+A) | After the final cold forming process the tubes are annealed in a controlled atmosphere. | |||||||||

| 5. NBK (+N) | After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere. | |||||||||

| Package | 1. Bundle Packing. | |||||||||

| 2. Plain end or vanished as per customer's request. | ||||||||||

| 3. Wrapped in waterproof paper. | ||||||||||

| 4. Sackcloth with several steel strips. | ||||||||||

| 5. Pack in heavy tri-wall boxes. | ||||||||||