Anping County Chant Wire Mesh Manufacturing Co.,Ltd |

|

Verified Suppliers

|

|

Product details:

| Product name | stainless steel wire mesh, steel wire mesh,woven wire mesh,wire screen,wire cloth |

| Stainless steel grade | 201 202 304 304L 316 316L or others |

| Special Material | copper,nickel,titanium,inconel,Monel, Hastelloy etc |

| Wire diameter | 0.018mm to 6.5 mm or customized |

| Pore hole size | 0.001mm to 20 mm |

| Mesh size | 0.3 mesh to 3500 mesh |

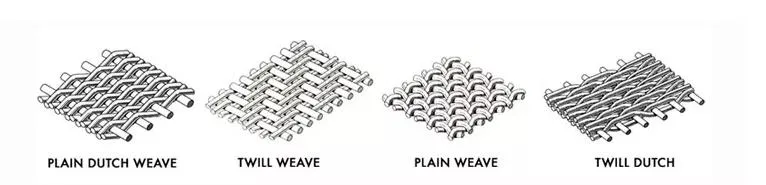

| Weave type | Plain Weave,Twill Weave,Dutch or 'Hollander' Weave,Plain Dutch Weave Twill Dutch Weave,Reverse Dutch Weave,Multiplex Weave. |

| Roll width | 0.3 to 10 meters |

| Roll length | 30 meters or customized |

| Processing services | Cutting/bending/welding and other services |

| Specification list of Stainless Steel Wire Mesh / Woven Wire Cloth | |||||||

| Meshes Per Linear Inch | Diameter of Wire | Width of Opening | Open Area, % | ||||

| Inches | mm | Inches | mm | ||||

| 1 | 0.135 | 3.5 | 0.865 | 21.97 | 74.8 | ||

| 1 | 0.120 | 3.0 | 0.880 | 22.35 | 77.4 | ||

| 1 | 0.105 | 2.5 | 0.895 | 22.73 | 80.1 | ||

| 1 | 0.080 | 2.0 | 0.920 | 23.36 | 84.6 | ||

| 3/4" | 0.120 | 3.0 | 0.630 | 16.00 | 70.5 | ||

| 3/4" | 0.080 | 2.0 | 0.670 | 17.01 | 79.8 | ||

| 2 x 2 | 0.120 | 3.0 | 0.380 | 9.65 | 57.8 | ||

| 2 x 2 | 0.105 | 2.5 | 0.395 | 10.03 | 62.4 | ||

| 2 x 2 | 0.080 | 2.0 | 0.420 | 10.66 | 70.6 | ||

| 2 x 2 | 0.063 | 1.6 | 0.437 | 11.10 | 76.4 | ||

| 2 x 2 | 0.047 | 1.2 | 0.453 | 11.50 | 82.1 | ||

| 3 x 3 | 0.080 | 2.0 | 0.253 | 6.42 | 57.6 | ||

| 3 x 3 | 0.063 | 1.6 | 0.270 | 6.85 | 65.6 | ||

| 3 x 3 | 0.047 | 1.2 | 0.286 | 7.26 | 73.6 | ||

| 4 x 4 | 0.080 | 2.0 | 0.170 | 4.31 | 46.2 | ||

| 4 x 4 | 0.063 | 1.6 | 0.187 | 4.75 | 56.0 | ||

| 4 x 4 | 0.047 | 1.2 | 0.203 | 5.15 | 65.9 | ||

| 5 x 5 | 0.047 | 1.2 | 0.153 | 3.88 | 58.5 | ||

| 5 x 5 | 0.041 | 1.0 | 0.159 | 4.01 | 63.2 | ||

| 6 x 6 | 0.063 | 1.6 | 0.104 | 2.64 | 38.9 | ||

| 6 x 6 | 0.047 | 1.2 | 0.120 | 3.04 | 51.8 | ||

| 6 x 6 | 0.035 | 0.9 | 0.132 | 3.35 | 62.7 | ||

| 8 x 8 | 0.063 | 1.6 | 0.062 | 1.57 | 24.6 | ||

| 8 x 8 | 0.047 | 1.2 | 0.078 | 1.98 | 38.9 | ||

| 8 x 8 | 0.035 | 0.9 | 0.090 | 2.28 | 51.8 | ||

| 8 x 8 | 0.032 | 0.8 | 0.093 | 2.36 | 55.4 | ||

| 8 x 8 | 0.028 | 0.7 | 0.097 | 2.46 | 60.2 | ||

| 10 x 10 | 0.047 | 1.2 | 0.053 | 1.34 | 28.1 | ||

| 10 x 10 | 0.035 | 0.9 | 0.065 | 1.65 | 42.3 | ||

| 10 x 10 | 0.032 | 0.8 | 0.068 | 1.27 | 46.2 | ||

| 10 x 10 | 0.025 | 0.63 | 0.075 | 1.90 | 56.3 | ||

| 12 x 12 | 0.041 | 1.0 | 0.042 | 1.06 | 25.4 | ||

| 12 x 12 | 0.035 | 0.9 | 0.048 | 1.22 | 33.2 | ||

| 12 x 12 | 0.032 | 0.8 | 0.051 | 1.29 | 37.5 | ||

| 12 x 12 | 0.028 | 0.7 | 0.055 | 1.39 | 43.6 | ||

| 12 x 12 | 0.023 | 0.58 | 0.060 | 1.52 | 51.8 | ||

| 14 x 14 | 0.032 | 0.8 | 0.039 | 1.52 | 29.8 | ||

| 14 x 14 | 0.025 | 0.63 | 0.046 | 0.99 | 41.5 | ||

| 14 x 14 | 0.020 | 0.5 | 0.051 | 1.30 | 51.0 | ||

| Please consult us for details about other sizes | |||||||

Weave Types

Anping Chant Metal Mesh Co.,Ltd. can provide many different weaves to meet different application needs.the weave styles mainly depend on the mesh and wire diameter specifications of the woven mesh. Below are the show of some common styles we weave here.

Mesh, Mesh Count, and Micron Size

Mesh Count and Micron Size are some of the important terms in the wire mesh industry.

The Mesh count is calculated by the number of the holes in an inch of mesh, so the smaller is the woven holes the bigger is the number of holes.The Micron Size refers to the size of the holes measured in microns. (The term micron is actually a commonly used shorthand for micrometer. )

In order to make it easier for people to understand the number of the holes of the wire mesh, these two specifications are usually used together. This is the key component of specifying the wire mesh. The Mesh Count determines the filtering performance and function of the wire mesh.

Micron Size = size of mesh hole. (larger the micron size, larger the mesh hole)

More intuitive expression:

Mesh Count = number of mesh hole. (larger the mesh count, the smaller the mesh hole)

Uses:

1. It is used for screening and filtering in acid and alkali environment, used as mud net in petroleum industry, chemical fiber industry, screen and electroplating. ...

2 Used in mining, petroleum, chemical industry, food, medicine, machinery manufacturing and other industries. ...

3. It can be used for screening and filtering in acid and alkali environment. It can be used as mud net in petroleum industry, screen in chemical fiber industry and acid washing net in electroplating industry. Our factory can design and manufacture various types of products according to users' needs. ...

Classification of stainless steel wire mesh products:

1. Plain stainless steel mesh:

The most common weaving method is widely used in industrial production and civil life, and its main feature is that the warp and weft diameters have the same density.

2. Stainless steel square mesh

Material: galvanized iron wire, stainless steel wire, copper wire, aluminum wire, etc. Features: Precise structure, uniform mesh, good corrosion resistance, firmness and durability. Widely used in industry and construction, screening sand, filtering liquid and gas. It can also be used for safety protection of mechanical accessories, etc., and it can also be used to make walls and ceilings instead of wooden strips.

3. Stainless steel dutch weave wire mesh

Material: stainless steel wire, low carbon steel wire, nickel wire, copper wire, polyester wire, etc. Weaving: plain weave, twill weave, bamboo weave and contrast weave. Features: Good filtering accuracy and high load strength of contrast net. Uses: It is used in aerospace, petroleum, chemical industry, scientific research and transportation industries, and can also be used to make lunch box nets, coal washing nets, etc.

Product features

1.Good acid resistance, alkali resistance and corrosion resistance;

2.High strength, strong tensile strength, toughness and wear resistance, durable;

3.Resistant to high temperature oxidation, the nominal temperature of 304 stainless steel screen is 800 degrees Celsius, and the nominal temperature of 310S stainless steel screen can reach 1150 degrees Celsius;

4.Processing at room temperature, that is, easy plastic processing, makes the use possibility of stainless steel screen diversified;

5.High smoothness, no surface treatment, convenient and simple maintenance.