Guangdong Huabao Xingye Automation Technology Co., Ltd |

|

Verified Suppliers

|

|

Round / Hex 3/8" Carbon Steel Swage Standoff Spacer Mounting Electronic Circuit Boards

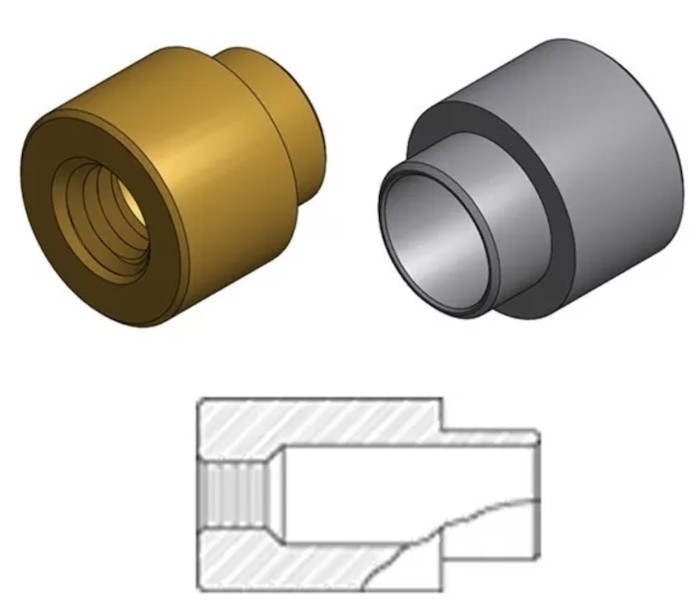

Much like their counterpart, swage spacer, the swage standoff is also used to create distance between object. Typically this style of parts are predominately used in curcuit board applications. Where the swage portion of the part is inserted (swaged) into previously mentioned board and another board is spaced properly. The female end of the swage standoff accepts a thread male part, most times a screw but could also be Male-Female Standoff. These parts are excellent to use when circuit boards are stacked one on top of another. Below is a list of standard swage standoffs parts we supply.

DIAMETER: 1/8" / 5/32" / 3/16" / 1/4" / 5/16" / 3/8"

SHAPE: Round and Hex

MATERIAL: Brass, Aluminum, Stainless Steel, Carbon Steel

BODY LENGTH: Wide variety of lengths- 1/32" (.031) increments up to 1"

SHANK LENGTH: Wide variety of lengths ranging from .062 through .295

FINISH: Available in 28 finishes

THREAD: 0-80 through 10-32 / Internal Thread- Class UNC 2B

INSIDE HOLE DIAMETER: Ranging from .063 through .194 for screw sizes

0-80 through 10-32

TOLERANCE: Body Length: ± .005 / Shank Length: ± .003 Inside Hole Diameter: + .000 - .003

Diameter: Standard commercial bar stock tolerances

We offer your firm engineering and design services for customized

or modified parts, at no additional charge- please contact our

Engineering Department.

Swage Standoffs & Swage Spacers 1/8" thru 3/8", 3mm thru 10mm-

Lengths: 1/32" thru 1", .5mm up to 51mm- Shank Lengths: .062 thru

.295.

Polestar swages round- hex, 28 finishes, available in brass,

aluminum, stainless steel, carbon steel. An inexpensive method of

spacing or mounting electronic circuit boards and electronic

components.

After installation they are permanently affixed to the board and

further assembly becomes simplified. Installation is accomplished

by using any means of force. Normal equipment, such as an arbor

press, punch press, are most commonly used. If swaging is planned,

the hole must be countersunk. For rivet type installation, an

ordinary drilled or punched hole, of the correct diameter, is

adequate. Available in both threaded and unthreaded / clear hole

types.

Spacers and Standoffs are two common types of positioning electronic hardware. They provide sturdy support, alignment and spacing to a variety of applications such as circuit board assemblies, panels and doors. Spacers and Standoffs are available in a variety of shapes, sizes and materials to meet the particular needs of your application. Round, hex, square, swage, female threads, male threads and even knurling for insert-like properties are all available. Non-magnetic and electrically neutral materials also help facilitate sensitive assembly requirements.

A Standoff is a fastener that is used to create space between two objects, often to properly position them. In the world of electronic compenents and electronic hardware, standoffs are typically used to space circuit boards, panels, doors or gears. Standoffs can be round, hexagonal or square in shape. They can have exterior knurling as well as swage characteristics. Female-Female or Double Female Standoffs can be fully threaded or partially threaded on each end. Male-Female Standoffs are also available. Standoffs are available in a variety of materials including aluminum, brass, plastic, steel and stainless steel.

Specifications:

A swage spacer is simply defined as an object that is used to create space between two object, often to properly position them. The style of parts are predominately used in curcuit board applications. Where the swage portion of the part is inserted (swaged) into previously mentioned board and another board is spaced properly. In the world of electronic compenents we typically see spacers used in a variety of situations. For instance one could space circuit boards, panels, doors or gears

Material Available for CNC parts

| Item | Shoulder Screws |

| Steel | 1018,1045,1050,1117,1141,1144,11L17,11L41,12L15,12L14,4140,4142,41L40,41L42, 8620,86L20,E52100, Fatigue proff, in cut 100, stress proof |

| Stainless steel | 17-4PH,302,303,304,316,321,416,440,420 |

| Aluminium | 2011,20246061,6063,6262,7075,5052 |

| Copper | 110,145,147,314,316,360,544,624,Berylium Copper |

| Zinc | zinc, zinc alloy |

| Plastic | ABS, PCB, PC, Nylon, Acetal, Celcon, Delron, Teflon |

| other | Bronze, Brass, Carbon Steel, Mild Steel, Hardened metal, Precious metal |

Technical specifications of auto lathe& cnc lathe machining

parts

| Item | OEM auto parts/CNC lathe parts/CNC Machining parts/CNC milling parts/CNC turning parts/CNC drilling parts |

| certification | ISO9001:2008,RoHs, |

| Machining equipments | CNC center, CNC milling machine, CNC turning machine, CNC drilling machine, CNC lathes, lathe, 4 axis machine etc. |

| Materials | Aluminum, Steel, Stainless steel, Brass, Copper, Bronze, ABS, PC, PO, POM, Nylon, Teflon etc. |

| Surface finish | Anodized, Oxide, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving etc. |

| Inspection Equipment | CMM, Projection, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

| Drawing format | PDF, JPG, PNG, DWG/DXF, IGS/STP etc |

Business Philosophy:

1. Quality is the soul of an enterprise.

2. Competitive price is our advantage.

3. Enthusiastic service is our tenet.

4. Innovation is our eternal pursuit

Quality Objectives:

1. Sample acceptance rate reaches 100%.

2. The qualified rate of finished products reaches 100%

3. Punctual delivery rate reaches 100%

Our Mission:

1.Strengthen management and continuously enhance satisfaction for customers, investors, suppliers and employees.

2. Enhance innovation capacity and contribute to sustainable development.

1. Best product quality and most competitive price.

2. Experienced technicians are in production.

3. High-end processing machines and inspection instruments.

4. Customized designs and production.

5. Excellent pre-sale and after-sale service.

Why choose us?

1. We are a professional manufacturer specializing in manufacturing various metal parts, including CNC precision automatic lathe machined parts, automatic lathe parts, milling machined parts, wire cutting machined parts etc.

2. With experienced technical engineers and modern inspection equipment, our factory can help you to lower cost at the moment of worldwide financial crisis.

3. We are committed to focusing on the client's demand and satisfaction, and to providing high quality products at competitive prices according to your drawings or samples. Special parts for your special needs!

4. Our strong R&D and QC department can control the products to meet your strict requirment, 100% inspection on critical dimensions with high accuracy +/-0.01-0.005mm.

5. Factory direct price and on time delivery.

6. Small quantity acceptable.

7. Free samples available.

8. OEM workable.

Q1: What is core and cavity insert?

A: The core and cavity are the two halves of the mold where the hot molten plastic material is injected into the core and cavity and the gap between the core and cavity is filled with the hot molten material during the injection molding process and then hardened into the final shape.

Q2: Why core is used in mold cavity?

A: A core is a device used in casting and moulding processes to produce internal cavities and reentrant angles (an interior angle that is greater than 180°). The core is normally a disposable item that is destroyed to get it out of the piece.

Q3: What are inserts in injection molding?

A: Insert injection molding is the process of molding or forming plastic parts around other, non-plastic parts, or inserts. The inserted component is most commonly a simple object, such as a thread or rod, but in some cases, inserts can be as complex as a battery or motor.

Q4: What is the difference between core and cavity?

A: The core is the male part which forms the internal shape of molding. The cavity is the female part which forms external shape of molding.

Q5: What are the different types of cooling cavity inserts?

A: Injection Molding Cooling Types and Layout:

1. Cooling line in core /cavity inserts.

2. Connecting cooling line between mold plates and inserts.

3. Different cooling line type.

4. Cooling tower.

5. Cooling line in lifter.

6. Cooling line in slider.