Anping Yuanqiao Petrochemical Equipment Co., Ltd |

|

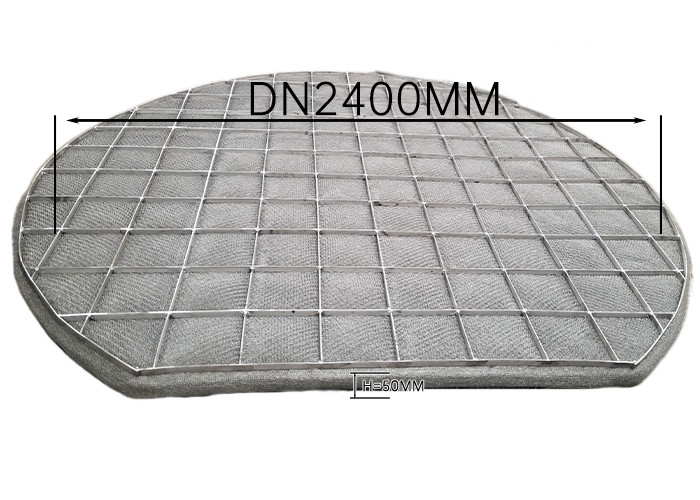

PTFE demister mesh stainless steel 316L grids gas liquid separator

PTFE demister characteristics:

The mechanical properties of polytetrafluoroethylene are relatively soft. It has very low surface energy. Polytetrafluoroethylene has a series of excellent performance:

PTFE demister efficiency:

When properly designed demister pads can give efficiency up to 99.9% with minimal pressure drop. Normally demister pads can remove droplets down to 5 microns and lower with a free volume of up to 99% and a surface area of up to 1940 m2/m3. Due to high value of free volume the pressure drop across the demister pad is sufficiently low in most applications.

Demister Inquiry Table if Calculation Suggestions and Service are needed

| Please State your demister / mist eliminator application | |||||

| Operating data | |||||

| Gas | Max. gas volume flow (operating conditions) | M3/h | |||

| Gas density (operating condistions) | Kg/m3 | ||||

| Operating pressure | Bar (a) | ||||

| Operating temperature | ℃ | ||||

| Liquid | Liquid content | Kg/h | |||

| Liquid density | Kg/m3 | ||||

| Dynamic viscosity of the liquid | mPas | ||||

| Geometrical data | |||||

| Flow direction | Horizontal | ¨ | |||

| Vertical | ¨ | ||||

| Installed in | Column | ¨ | |||

| Pipe | ¨ | ||||

| Column diameter or dimensions | mm | ||||

| Opening for installation | Manhole | ¨ DN | |||

| Vessel flange | ¨ Size | ||||

| Requirements | |||||

| type of mist eliminator | Wire mesh demister | ||||

| Material | |||||

| Efficiency of separation | % | ||||

| Max. pressure drop | |||||

| Miscellaneous | |||||

Please pay attention to the Unit when refering to this sheet.