Phidix Motion Controls (Shanghai) Co., Ltd. |

|

Verified Suppliers

|

|

Custom Push Pull Control Cable Various Material Simple Install Easy Maintain

【Product Description】

We offer a full range of push-pull controls that provide a means of transmitting linear motion from one location to another. They offer ease of installation as well as superior performance.

【 Cable Types 】

V = 10-32, L = 1/4-28, M = 5/16-24, H = 3/8-24.

(Very light duty; Light duty; Medium duty; Heavy duty)

【 Applicationss 】

• Implement control

• Throttle control

• PTO/4WD activation

• Valve actuation

• Remote battery disconnect

• Remote electrical disconnect

• Transmission shift

• Hydrostatic drives

• Latches

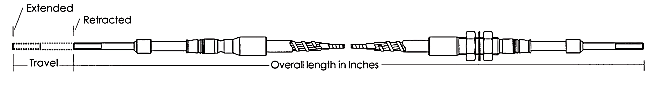

【 Standard Push-Pull Cable Terminology 】

【 How To Ldentify Push-Pull Cables 】

Your goal is to determine the information required to make up the “ordering code” or part number. An example of a typical ordering code is 173-VTG-3-144.

Step 1: Determine the “duty” (size) of the cable by the diameter and threads of the end rods. V = 10-32, L = 1/4-28, M = 5/16-24, H = 3/8-24.

(Very light duty; Light duty; Medium duty; Heavy duty)

Step 2: Determine the type of conduit end fittings (conduit caps) for left end and right end. T = Threaded, G = Grooved. TT, GG or TG combinations.

Step 3: Determine the travel of the end rod. 1 through 6 in one inch increments.

Step 4: Determine the overall length of the cable.

Step 5: Determine cable materials depending on usage and conditions.

See details of 173, 174, 175 Utility, 313, 314, 315 Low Friction EXT and 183,184 and 185 Low Friction.

Utility: “The Rugged Gray Cable” is the industry-standard and is designed for a long life under rugged conditions (173, 174, 175).

Low Friction EXT: “The Green Cable” is the proper cable to use when superior efficiency is required. The extruded nylon cover over the innermember works very smoothly with the polyliner (313, 314, 315).

Low Friction: The proper cable to use when superior efficiency is required. The bonded PTFE cover over the inner operating member works very smoothly with the plastic liner (183, 184, 185).

【 Real Picture 】