MBS Hardware Co. Ltd |

|

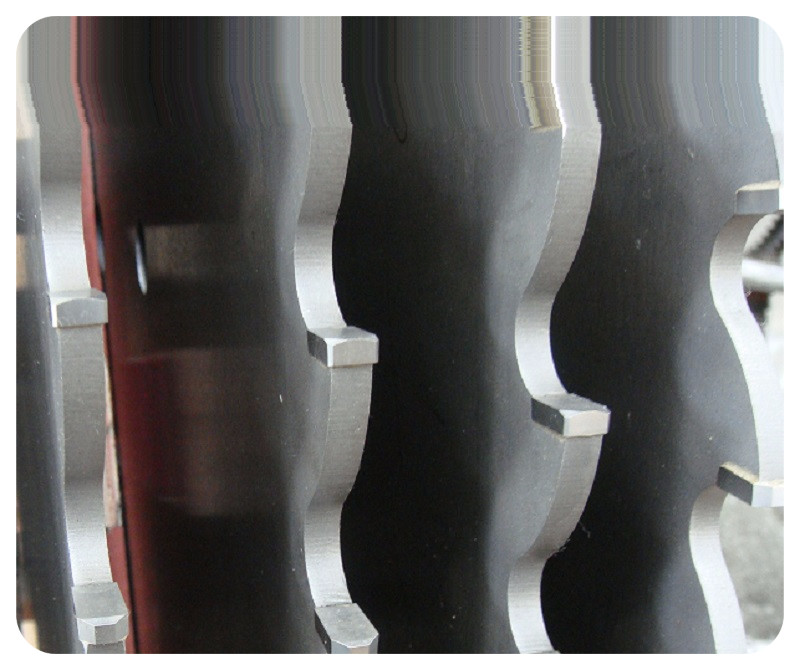

steel cutting blade for circular saw INDUSTRIAL TCT Circular Saw Blades for cutting steel ingot and steel block

This type of TCT Circular Saw Blades are specially designed as steel ingot cutting blades. The blades are applied in steel plant, seamless steel pipe plant, wheel hub plant and other heavy machinery factory to cut steel ingot, big diameter steel bar, steel rails and other big size steel profiled bars. The blades also can be used to cut cast iron and non-ferrous metals like aluminium, cooper, brass etc…

Quality: for indutrial and professional market

Bore: all sizes and upon request, including 60mm, 80mm, 100mm, 150mm, etc

Teeth number could be adjusted upon request.

Teeth type:

Size and specifications:

| Diameter (mm) | Kerf (mm) | Body Thickness (mm) | Teeth number |

| 450 | 6 | 4.5 | 52 |

| 540 | 6.5 | 5.0 | 60/80 |

| 630 | 6.5 | 5.0 | 60/80 |

| 660 | 6.5 | 5.0 | 70/80 |

| 710 | 7 | 5.5 | 60/70/80 |

| 760 | 7 | 5.5 | 60/70/80 |

| 830 | 7 | 5.5 | 70/100 |

| 965 | 8 | 6.5 | 50/60/90 |

| 1010 | 8 | 6.5 | 60/80 |

| 1080 | 8 | 6.5 | 60/80 |

| 1140 | 8 | 6.5 | 48/50/60/70/72 |

| 1180 | 8 | 6.5 | 54/60/70/80 |

| 1250 | 8.5 | 7.0 | 50/54/80 |

| 1320 | 8.5 | 7.0 | 50/60/80 |

| 1500 | 9.5 | 8.0 | 50/80 |

| 1800 | 10.5 | 9.0 | 60/90 |

Remark: Other special izes and specification can be tailor-made for our clients.

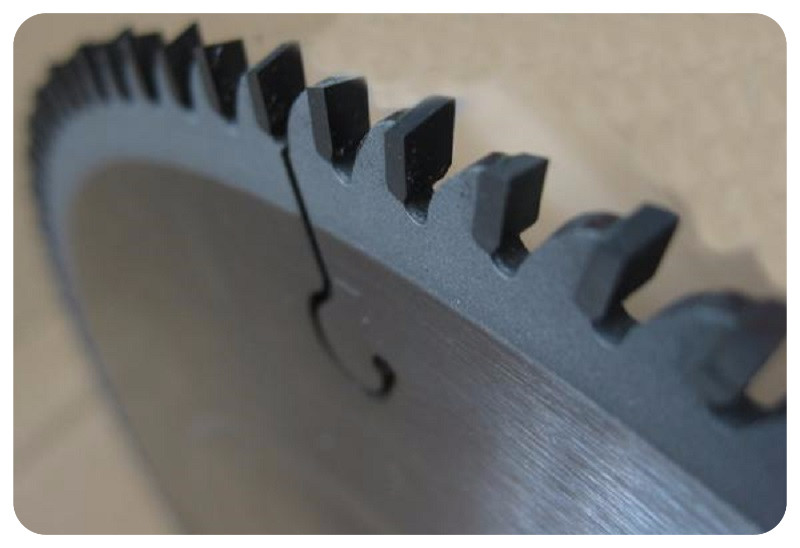

There are four basic blade types, determined by the shape, or grind, of their teeth. They are flat top grind (FTG), alternate top bevel (ATB), combination (ATBR), and triple-chip grind (TCG) [Figure 1 and Photo A].

FTG blades have teeth whose top edges are square to the saw plate. Also called rakers, these teeth attack the wood much like a chisel chopping out the ends of a mortise. They’re fast cutting and durable, but don’t produce a clean surface. They’re designed to rip, sawing perpendicular to the grain.

The teeth on ATB blades are angled across the top edge, with every other tooth “leaning” in the opposite direction. The shape of the tooth causes it to shear the wood fibers cleanly using a slicing motion. The steeper the bevel angle, the cleaner the teeth cut, but the quicker they dull (Figure 2). Most 40-tooth ATB blades are marketed as “all-purpose” blades.

Combination blades consist of 50 teeth arranged in sets of five, with four ATB teeth followed by a raker tooth (thus the ATBR designation.) The ATB teeth are designed to crosscut cleanly while the raker teeth aid in ripping. Combination blades are also considered “all-purpose” blades.

The teeth on a TCG blade alternate between a raker tooth and a chamfered tooth. The chamfered tooth roughs out the cut, while the following FTG tooth cleans it up. This tooth configuration is meant for sawing dense materials: plastic laminate, solid surface materials like Corian, and non-ferrous metals like brass and aluminum. Pointy ATB teeth would blunt quickly from this stuff.