Hangzhou Kaihong Membrane Technology Co., Ltd. |

|

Verified Suppliers

|

|

8040W Ulta-filtration Membrane Modules for Purified Water Treatment with Pore Size 0.03um PVDF material

1. Brief Introduction

Ultrafiltration (UF) involves pressure-driven separation of materials from a feed solution. The technology is used to remove particulate and microbial contaminants, but it does not remove ions and small molecules. Pressure drives the process, which typically operates with a feed pressure of 4 to 100 psi. UF plants are automated and have low operational labor requirements. UF membranes have a service life of three to five years or longer, which is comparable to reverse osmosis membranes.

UF modules are commercially available in tubular, hollow-fiber, plate and frame, and spiral wound configurations.

UF membranes reject solutes ranging size from 0.01 microns to 0.1 microns. Equal to the molecular weight cut-off (MWCO) 1000-500,000 daltons.

Different membrane materials with the same nominal MWCO may have different rejection rate. Because the pore size distribution and uniformity affect the reject performance.

The chemical nature of the membrane material also affect the membrane fouling-rejection.

So the membrane flux rate, rejection performance and anti-pollution performance are most important for different UF modules.

2. Description of ultrafiltration modules

2.1 Module Features

The CNKHONG Ultrafiltration modules are made of high strength hollow fiber membranes, they are made of Polyvinylidene Fluoride(PVDF). The pore size of 0.03 µm is enough for the removal of bacteria, viruses, and particles including all kinds of colloids. v

The membranes have been special treated to be hydrophilic. It is easy cleaning and wettability that help maintain long term performance. v Out to In flow configuration can endure high tolerance of feed solids. They also can be used pressed air to help the cleaning recovery.

The dead-end filtration way offer higher recovery rate and energy savings. The largest water recovering rate can be more can 95%.

2.2 Structure and Specifications of UF Membrane Modules

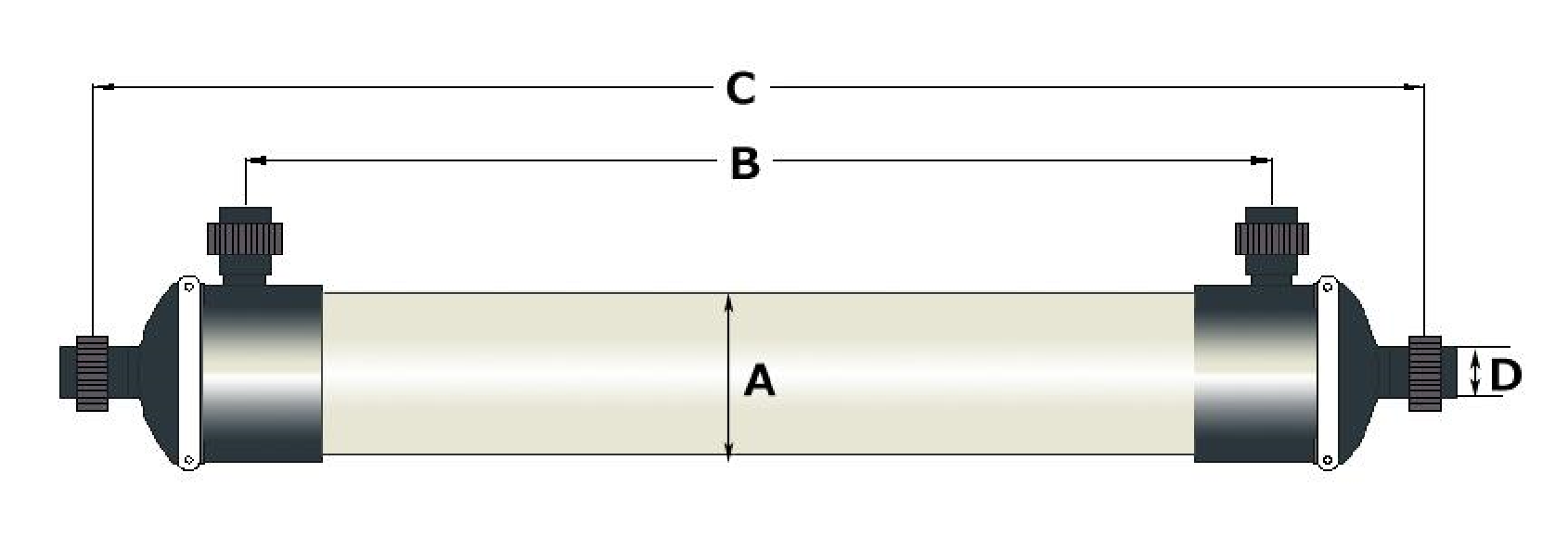

2.2.1 Small size of UF modules

Size and weight

| Model | KH-UF-4040W-PVDF | KH-UF-6040W-PVDF |

| Module Diameter ( A, mm) | Φ90 mm | Φ160 mm | |

| Module Length ( B, mm) | 960mm | 960mm | |

| Module Length (C, mm) | 1106 mm | 1304 mm | |

| Size of Inlet/Outlet (D, mm) | DN25 | DN32 | |

| Operating Type | Outside to Inside | Outside to Inside | |

| Membrane Area | 8.0 m2 | 20 m2 | |

| Dry weight of the module | 5 Kg | 12 Kg | |

Parameters | Shell material | UPVC | UPVC |

| Membrane Material | PVDF | PVDF | |

| Membrane pore size | 0.03μm | 0.03μm | |

| Inner diameter of the hollow fiber | 0.7 mm | 0.7 mm | |

| Outer diameter of the hollow fiber | 1.3mm | 1.3mm | |

| Turbidity of Permeating water | ≤ 0.2NTU | ≤ 0.2 NTU | |

SDI value of permeating water

| ≤ 3 | ≤ 3 | |

Flux rate of purified water (0.10MP,20℃) | ≥1000L/H | ≥3000L/H | |

Typical Process

| Temperature Range | 5-45 ℃ | 5-45 ℃ |

| PH Value Range | 2-13 | 2-13 | |

Permeating Flux rate for different Water | 40 - 80 l/m2/hr | 40 -80 l/m2/hr | |

| Operating Pressure | ≤0.12 MPa | ≤0.12MPa | |

| Maximum Inlet Pressure | 0.2 MPa | 0.2MPa | |

| Backwashing flux rate | 1.5-2.0 times of Permeating Flux | 1.5-2.0 times of Permeating Flux | |

| Backwashing times | Once per 30-120 minutes | Once per 30-120 minutes | |

| Chemical cleaning online during backwashing | Once per 7-14 days | Once per 7-14 days |

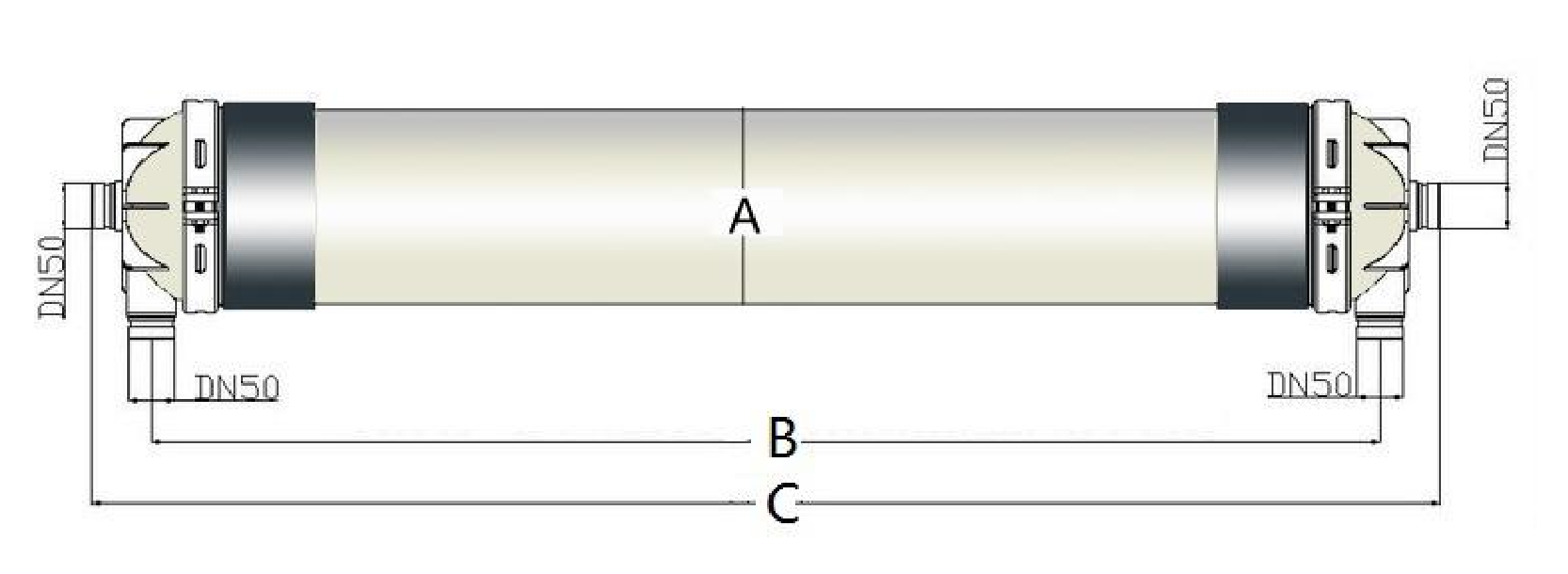

The structure as the following:2.2.2 type A of 8 inches UF module.

Size and weight

| Model | KH-UF-8040W-PVDF | KH-UF-8060W-PVDF |

| Module Diameter ( A, mm) | Φ200 mm | Φ200 mm | |

| Module Length ( B, mm) | 1220 mm | 1640 mm | |

| Module Length (C, mm) | 1365 mm | 1785 mm | |

| Size of Inlet/Outlet | DN50 | DN50 | |

| Operating Type | Outside to Inside | Outside to Inside | |

| Membrane Area | 30 m2 | 45 m2 | |

| Dry weight of the module | 20 Kg | 35 Kg | |

Parameters | Shell material | UPVC | UPVC |

| Membrane Material | PVDF | PVDF | |

| Membrane pore size | 0.03μm | 0.03μm | |

| Inner diameter of the hollow fiber | 0.7 mm | 0.7 mm | |

| Outer diameter of the hollow fiber | 1.3mm | 1.3mm | |

| Turbidity of Permeating water | ≤ 0.2NTU | ≤ 0.2 NTU | |

SDI value of permeating water

| ≤ 3 | ≤ 3 | |

Flux rate for of purified water (0.10MP,20℃) | ≥ 3600L/H | ≥ 5400L/H | |

Typical Process

| Temperature Range | 5-45 ℃ | 5-45 ℃ |

| PH Value Range | 2-13 | 2-13 | |

Permeating Flux rate for different Water | 40 - 80 l/m2/hr | 40 -80 l/m2/hr | |

| Operating Pressure | ≤0.12 MPa | ≤0.12MPa | |

| Maximum Inlet Pressure | 0.2 MPa | 0.2MPa | |

| Backwashing flux rate | 1.5-2.0 times of Permeating Flux | 1.5-2.0 times of Permeating Flux | |

| Backwashing times | Once per 30-120 minutes | Once per 30-120 minutes | |

| Chemical cleaning online during backwashing | Once per 7-14 days | Once per 7-14 days |

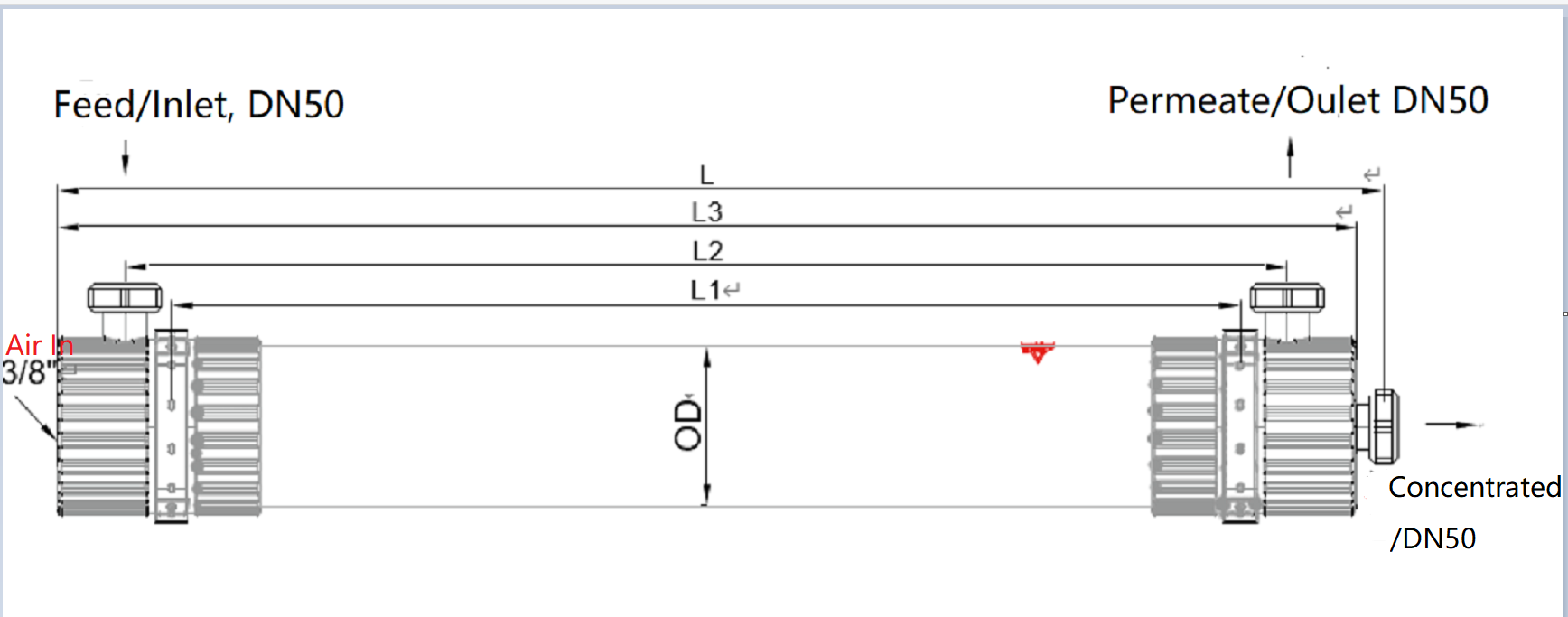

2.2.3 type B of 8 inches UF module. The structure as the following:

Size and weight

| Model | KH-UF-SFX2860-PVDF | KH-UF-SFX2880-PVDF |

| Module Diameter (OD, mm) | Φ225 mm | Φ225 mm | |

| Module Length ( L1, mm) | 1500 mm | 2000 mm | |

| Module Length (L2, mm) | 1630 mm | 2130 mm | |

| Module Length (L3, mm) | 1820 mm | 2320 mm | |

| Module Length (L , mm) | 1860 mm | 2360 mm | |

| Operating Type | Outside to Inside | Outside to Inside | |

| Membrane Area | 52 m2 | 77 m2 | |

| Dry weight of the module | 42 Kg | 62 Kg | |

Parameters | Shell material | UPVC | UPVC |

| Membrane Material | PVDF | PVDF | |

| Membrane pore size | 0.03μm | 0.03μm | |

| Inner diameter of the hollow fiber | 0.7 mm | 0.7 mm | |

| Outer diameter of the hollow fiber | 1.3mm | 1.3mm | |

| Turbidity of Permeating water | ≤ 0.2NTU | ≤ 0.2 NTU | |

SDI value of permeating water

| ≤ 3 | ≤ 3 | |

Flux rate of purified water (0.10MP,20℃) | ≥ 6500L/H | ≥ 8000L/H | |

Typical Process

| Temperature Range | 5-45 ℃ | 5-45 ℃ |

| PH Value Range | 2-13 | 2-13 | |

Permeating Flux rate for different Water | 40 - 80 l/m2/hr | 40 -80 l/m2/hr | |

| Operating Pressure | ≤0.12 MPa | ≤0.12MPa | |

| Maximum Inlet Pressure | 0.2 MPa | 0.2MPa | |

| Backwashing flux rate | 1.5-2.0 times of Permeating Flux | 1.5-2.0 times of Permeating Flux | |

| Backwashing times | Once per 30-120 minutes | Once per 30-120 minutes | |

| Chemical cleaning online during backwashing | Once per 7-14 days | Once per 7-14 days |

The whole installation and application process of our MBR modules

are described as the following photo: