Hangzhou Kaihong Membrane Technology Co., Ltd. |

|

Verified Suppliers

|

|

MBR membrane module for Wastewater Treatment with PVDF material

Reduced sludge production: MBR systems produce less sludge compared to conventional wastewater treatment systems, resulting in lower disposal costs.

Reuse potential: The high-quality treated water produced by MBR systems can be reused for irrigation, industrial processes, and other non-potable uses.

2. Advantages of MBR

1). High-quality effluent: MBR technology can produce high-quality treated water that meets stringent regulatory standards for discharge or reuse.

2). Small footprint: MBR systems are compact and require less space compared to conventional wastewater treatment systems. This makes them suitable for installations where space is limited or where land is expensive.

3). Process flexibility: MBR technology can handle variations in wastewater flow and load, making it suitable for both municipal and industrial wastewater treatment applications.

4). Enhanced biological treatment: MBR technology provides an ideal environment for microorganisms to thrive, resulting in enhanced biological treatment performance.

5). Improved solids removal: MBR systems can remove a high percentage of solids from the treated water, reducing the need for downstream treatment.

3. Technical Parameter of Membrane Module

| Item/Model | KH-MBR-8-CO-PVDF | KH-MBR-12-CO-PVDF | KH-MBR-18-CO-PVDF |

| Membrane Area(M2) | 8 | 12 | 18 |

| Height | 1050 mm | 1550 mm | 1800 mm |

| Width | 645 mm | 645mm | 645 mm |

| Thickness | 47 mm | 47mm | 47mm |

| Dry Weight | 6kgs | 10kgs | 15 kgs |

| Membrane material | Reinforced PVDF | Reinforced PVDF | Reinforced PVDF |

| Micro pore size | 0.05μm | 0.05μm | 0.05μm |

| ID/OD of Membrane | 0.9/2.2mm | 0.9/2.2mm | 0.9/2.2mm |

| Suspend solid | <5mg/L | <5mg/L | <5mg/L |

| Temperature | 5-40℃ | 5-40℃ | 5-40℃ |

| PH range | 2~11 | 2~11 | 2~11 |

| Flux for waste water | 15~20 LMH | 15~20 LMH | 15~20 LMH |

| Operating Method | Sucking out 8 mins and staying 2 mins | Sucking out 8 mins and staying 2 mins | Sucking out 8 mins and staying 2 mins |

| Cleaning Chemicals | 500-3000ppm Sodium hypochlorite | 500-3000ppm Sodium hypochlorite | 500-3000ppm Sodium hypochlorite |

1. Introduction of MBR

Membrane Bio Reactor (MBR) is a wastewater treatment technology that combines biological treatment with membrane filtration. The MBR system uses microorganisms to degrade organic pollutants in the wastewater, and a membrane filtration system to remove the suspended solids, bacteria, and viruses from the treated water.

The MBR process involves the use of a membrane filtration module that is submerged in an aeration tank where biological treatment occurs. The membrane module typically consists of thousands of tiny hollow fibers or flat sheets that act as a barrier, allowing only clean water to pass through while retaining the solids, bacteria, and other contaminants.

MBR technology has several advantages over conventional wastewater treatment systems, including higher effluent quality, smaller footprint, and greater process flexibility. However, MBR systems are typically more expensive to install and maintain than conventional systems, and require more energy for aeration and membrane cleaning. MBR systems are commonly used in a variety of applications, including municipal wastewater treatment, industrial wastewater treatment, and decentralized wastewater treatment.

| Item/Model | KH-MBR-25-CO-PVDF | KH-MBR-30-CO-PVDF | KH-MBR-35-CO-PVDF |

| Membrane Area(M2) | 25 | 30 | 35 |

| Height | 1560 mm | 1810 mm | 1810 mm |

| Width | 1040 mm | 1040 mm | 1250 mm |

| Thickness | 47 mm | 47mm | 35 mm |

| Dry Weight | 20 kgs | 25 kgs | 30 kgs |

| Membrane material | Reinforced PVDF | Reinforced PVDF | Reinforced PVDF |

| Micro pore size | 0.05μm | 0.05μm | 0.05μm |

| ID/OD of Membrane | 0.9/2.2mm | 0.9/2.2mm | 0.9/2.2mm |

| Suspend solid | <5mg/L | <5mg/L | <5mg/L |

| Temperature | 5-40℃ | 5-40℃ | 5-40℃ |

| PH range | 2~11 | 2~11 | 2~11 |

| Flux for waste water | 15~20 LMH | 15~20 LMH | 15~20 LMH |

| Operating Method | Sucking out 8 mins and staying 2 mins | Sucking out 8 mins and staying 2 mins | Sucking out 8 mins and staying 2 mins |

| Cleaning Chemicals | 500-3000ppm Sodium Hypochlorite | 500-3000ppm Sodium Hypochlorite | 500-3000ppm Sodium hypochlorite |

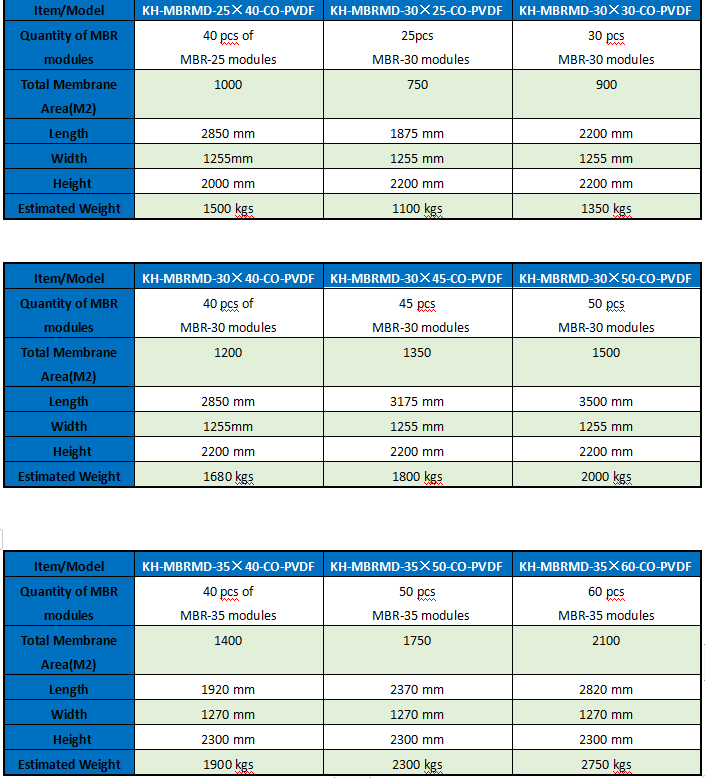

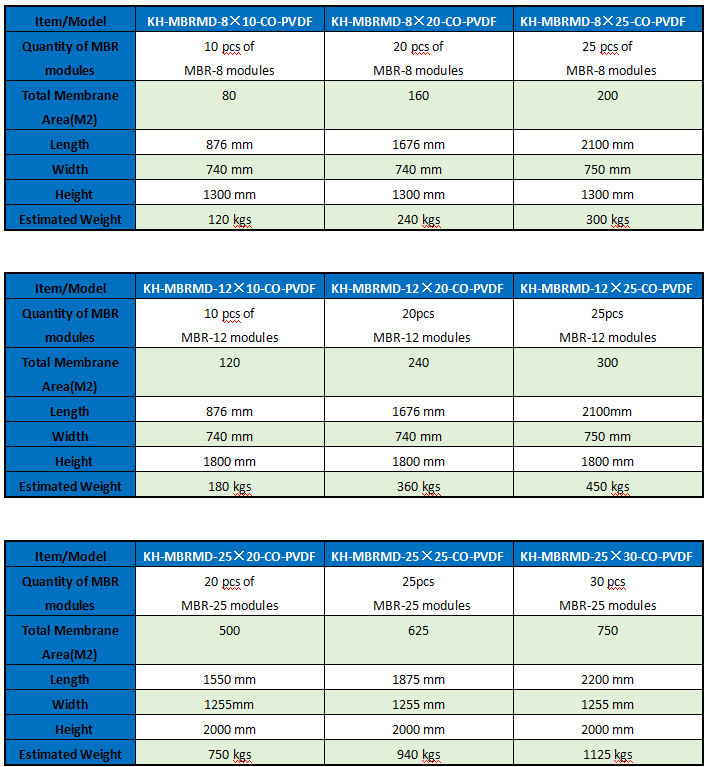

2. Typical parameters of MBR units.

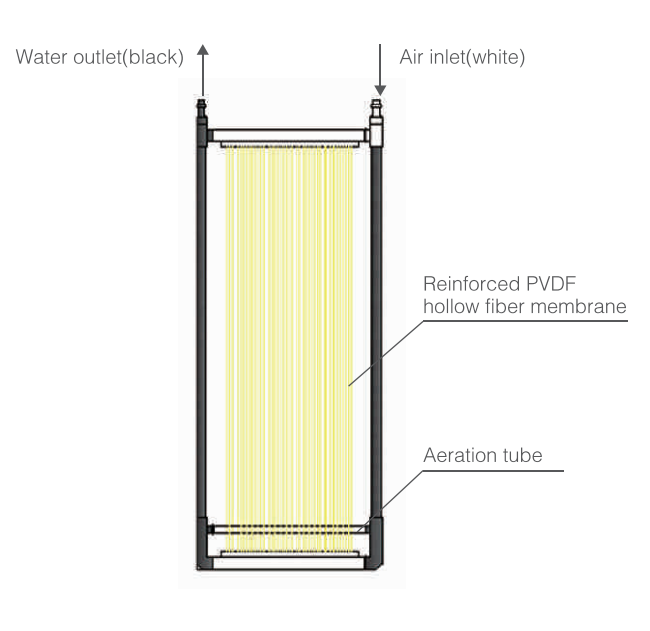

4.. Structure of Membrane Modules and Frames:

A. Structure of MBR Modules

B.Structure of MBR Frames

5. Product Features

-- All the frames are made of SS 304 or SS 316 stainess steel with reliable frames.

-- Every modules can be pulled out or putted in very conveniently for they are installed into UPVC Groove from top to bottom.

-- Every modules have flexible tubes connecting to collecting pipes.

-- Every modules have independent air blowing tube. There are additional air-blowing tube at the bottom of the frames.

-- All the modules have an added patented design air blowing tube to enhance the efficiency of the air blowing onto the membrane surface.

-- Permanent Hydrobility Membrane

-- Strong strength, the broken strength more than 50MPa

-- Excellent performance and Low cost

6. Application of MBR Units:

The whole installation and application process of our MBR modules are described as the following photo:

A. MBR unit of KH-MBRMD-30×28-CO-PVDF with total membrane area of 840 m2/unit.

B. MBR unit of KH-MBRMD-35×60-CO-PVDF with total membrane area of 2100 m2/unit.

Packing & Delivery

Why Choose US?

1). Over 20 years experience in UF and MBR membrane

2). Excellent cooperation partner

3). Own an excellent technical team

4). Advanced R & D capability

5). International management system

6). Located in Jiangsu, convenient export transportation.

Our Service

1). MBR membrane technical consulting,

2). MBR membrane application engineering design,

3). MBR system manufacturing, installation and commissioning,

4). Different membrane dimension, material like pp, PVDF,reinforced

PVDF etc.,can be customize according to your requirements

5). 12 months warranty

FAQ

Q: Are you trading company or manufacturer?

A:We are the leading professional manufacturer in China, more than 20 years experience in the waste water treatment.

Q:What about the lead time?

A:Sample needs within 3 days, mass production needs 1-2 weeks after down payment.

Q:Can I have a sample order for UF/MBR Membrane?

A: Yes, we welcome sample order to test and check quality. Mixed

samples are acceptable.

Q:Is it acceptable to print my logo on UF Membrane product?

A: Yes. Please inform us formally before our production and confirm

the design firstly based on our sample.

Q:What's the information we need to know?

A1: what's your raw water ?

B1: what's the capacity per hour of the equipment ?

C1: What's the application of purifier water ?