PingYang DEM Auto Parts Factory |

|

Verified Suppliers

|

|

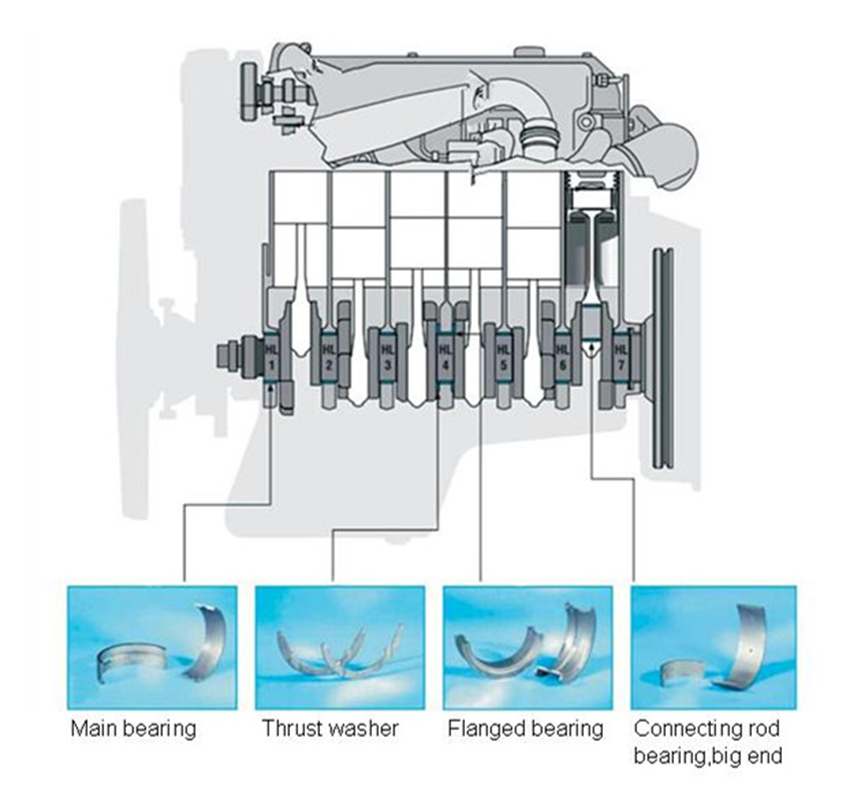

Audi 80 A4 Avant Engine Main Bearing For Audi 20-479/5A 1.6L Wear Resistant

Product Specification

| Model | Audi 80 A4 Avant Engine Main Bearing For Audi 20-479/5A 1.6L Wear Resistant |

| Specification | STD 0.25 0.50 0.75 1.00 |

| Brand | TAJHO |

| Weight | 1.27kg/PC |

| Material | Aluminum-based |

| SIZE | Standard |

| Application | Machinery parts/Automobile Parts |

| Quality | ISO 9001:2008 ISO/TS16949 standard |

| Precision | 0.013mm |

| Service | OEM available |

Company Introduction

The company mainly produces various types of bearing shells, including but not limited to cylindrical bearing shells, cover plate bearing shells, and sliding bearing shells, which are widely used in mechanical equipment, automotive industry, aerospace, and energy fields. The company has won the trust and support of customers with stable and reliable product quality and highly competitive prices. The company has a research and development team composed of experienced engineers and technical personnel, who have profound professional knowledge and innovative spirit, and are constantly monitoring the latest development trends in the industry. The company focuses on technological innovation and quality improvement, adopting advanced production processes and equipment to ensure the accuracy and durability of products.

Temperature monitoring: Use a suitable thermometer to regularly measure the working temperature of the bearing shells. Abnormal heating may indicate poor friction or insufficient lubrication.

Maintenance: According to the equipment manufacturer's maintenance manual, carry out regular maintenance work, such as lubricating oil replacement, inspection and tightening of fasteners, etc

Observation: Regularly inspect the surface of the bearing pads for abnormal wear, cracks, or deformation.

Lubrication status monitoring: By analyzing grease or lubricating oil, determine the lubrication status of bearing shells, and promptly identify and solve problems.

Product Technology

The manufacturing process of bearing shells involves multiple stages, including raw material preparation, precision machining, surface treatment, size detection and adjustment, assembly and testing. By strictly following the process requirements, we can ensure the production of high-quality bearing shells that meet the design requirements.

As an indispensable and critical component of mechanical equipment, in the transmission system of railway vehicles, bearing pads are used to support and guide wheel axles, ensuring smooth train operation and reducing wear and tear on wheels and tracks.