PingYang DEM Auto Parts Factory |

|

Verified Suppliers

|

|

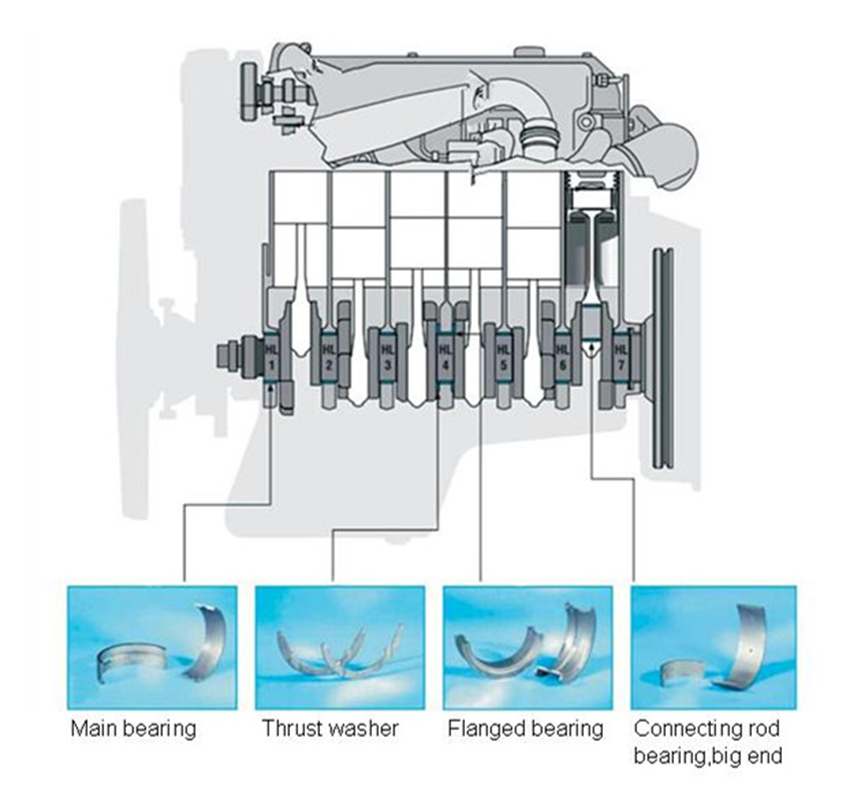

For Chevrolet Engine Main Bearing L6-250 2.0L 20-062/7A High Preiciency

Product Specification

| Model | For Chevrolet Engine Main Bearing L6-250 2.0L 20-062/7A High Preiciency |

| Brand | TAJHO |

| Weight | 1.28kg/PC |

| Material | Aluminum-based |

| SIZE | Standard |

| Application | Machinery parts/Automobile Parts |

| Quality | ISO 9001:2008 ISO/TS16949 standard |

| Precision | 0.013mm |

| Service | OEM available |

Product Operation

Before operating the bearing shells, it is necessary to ensure that the working environment is clean and tidy, free of debris and dust, and to maintain good ventilation. When installing or disassembling bearing shells, carefully read the equipment operation manual and follow the instructions. Special attention should be paid to keeping the surface of the bearing shells clean, using appropriate lubricants during installation, and ensuring even installation force to avoid unnecessary damage.

Product Process

The surface treatment of bearing shells aims to improve their friction and wear resistance. Common surface treatment methods include carburization, copper plating, spraying, etc. Carburization can increase the hardness and wear resistance of the bearing surface, while copper plating can improve its thermal conductivity and corrosion resistance. Select appropriate surface treatment methods according to specific requirements for treatment.

The surface treatment of bearing shells aims to improve their friction and wear resistance. Common surface treatment methods include carburization, copper plating, spraying, etc. Carburization can increase the hardness and wear resistance of the bearing surface, while copper plating can improve its thermal conductivity and corrosion resistance. Select appropriate surface treatment methods according to specific requirements for treatment.

The precision machining of bearing bush is one of the Committed step, which determines the dimensional accuracy and surface quality of bearing bush. This process typically includes processes such as turning, milling, drilling, and grinding. By precise machining and trimming of the bearing blank, the size and shape required by the design can be achieved

As an indispensable and critical component of mechanical equipment, in the transmission system of railway vehicles, bearing pads are used to support and guide wheel axles, ensuring smooth train operation and reducing wear and tear on wheels and tracks