Jiangsu emt Technology Co., Ltd. |

|

Verified Suppliers

|

|

Mg-Al-Zn Alloy Car Seat Accessories Light OEM Magnesium Auto Parts CNC Turning

Description:

| Material | Magnesium alloy etc. |

| Surface treatment | Powder coating, electroplating, oxide, anodization |

| Technics | One piece,laser cut, bend, weld, stamp |

| Drawing Formats | PRO/E, Auto CAD, Solid Works, UG, CAD/ CAM / CAE, PDF |

Tolerance | Surface Roughness | +/-0.005-0.01mm | Ra0.2 - Ra3.2 (Customize avaiable ) |

| Processing | CNC Turning, Milling parts, Dilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. |

| Testing Equipment | CMM / Tool microscope / multi-joint arm / Automatic height gauge / Manual height gauge / Dial gauge / Roughness measurement |

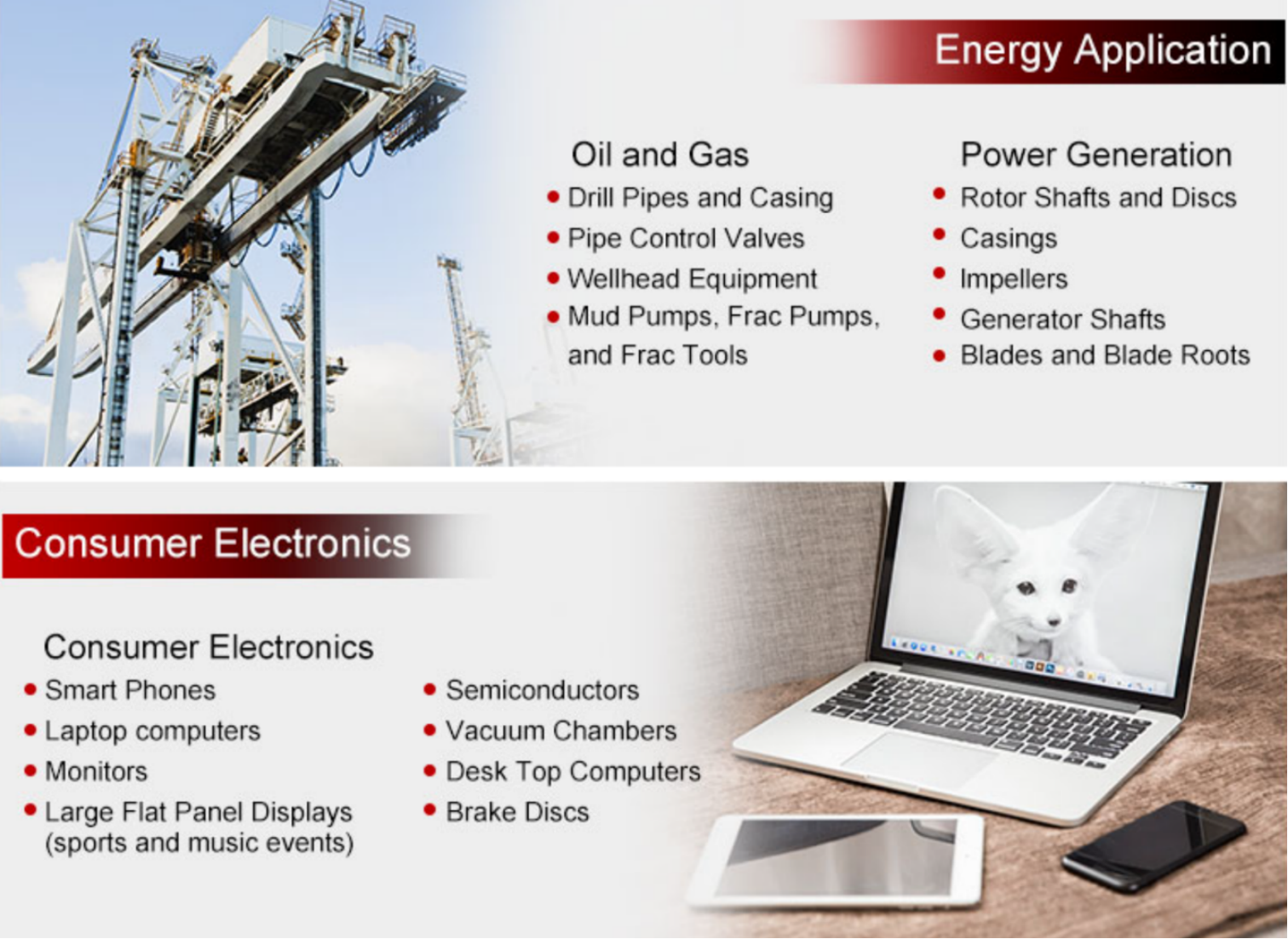

| Application | Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medicaldevice, Telecommunications |

Specification:

| Product name | support frame | |

| Specification | Auto parts | |

| Unit weight | 0.6KG | |

Advantage:

Magnesium alloy has good machining performance and dimensional stability:

Magnesium alloy has good cutting performance, low cutting tool consumption and low cutting power. The power ratio of magnesium alloy, aluminum alloy, cast iron and low alloy steel in cutting the same parts is: 1:1:8:3:5:6.3. Magnesium alloy has high dimensional stability, stable shrinkage rate, high dimensional accuracy of casting and workpiece, except mg-al-Zn alloy, most of the magnesium alloy in the heat treatment process and long-term use due to phase transformation caused by the dimensional change is close to zero.

Advantage:

FAQ:

1. Q:Are you a factory or a trading company?

A:We are a factory which has been focus on Magnesium alloy deep processing lightweight field & semi-solid injection molding of Magnesium alloy for more than 16+ years.

2. Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control.

3. Q: Has the company established and implemented a standard procedure for purchasing contract review and approval?

A: Yes, with written standard procedures.

4. Q: Is there a procedure to conduct random product inspections after final packaging?

A: Yes, with clear standard and written inspection records.

5. Q: How can I get a quotation?

A: Please kindly send us following information 1) Product drawings by STEP/STP/PRT/PDF/IGS format etc. 2) Material, size and surface treatment request. 3) Required quantity. Normally,the quote will be offer in 1-6 hours. :)

6. Q: What is your payment terms?

A: T/T, Western Union, etc.