Xi'an Yuechen Metal Products Co., Ltd |

|

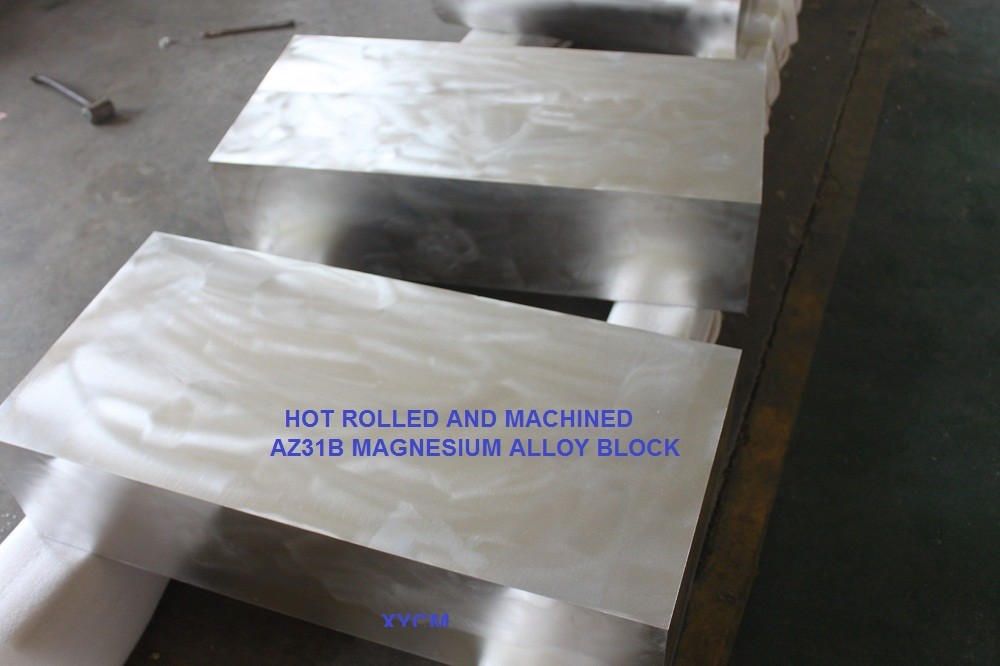

Magnesium Alloy Plate ASTM standard Hot Rolled AZ31B-H24 Magnesium plate for Vibration Testing Equipment

APPLICATION

Those applications requiring a flat surface or high dimensional stability benefit from the use of magnesium tooling plate. Typical uses included jigs, fixtures, optical benches, vibration test equipment and inspection gauges. Magnesium Tooling Plate is non-magnetic and has high electrical and thermal conductivity filling many material requirements in the electronics and computer industries.

Magnesium Tooling Plate Flatness Tolerances

Max. deviation from flat as measured by a straight edge placed on plate surface.

| Specified Plate Gauge | Max. allowed deviation from flat | |||

| Over (mm) | Thru (mm) | In any 300mm | In any 1500mm | In any 2000mm |

| 6.3 | 25 | 0.125mm | 0.31mm | 0.42mm |

| 25 | 150 | 0.250mm | ||

| Specified Plate Gauge | Typical tooling plate deviation from flat | |||

| Over (mm) | Thru (mm) | In any 300mm | In any 1500mm | In any 2000mm |

| 6.3 | 25 | 0.077mm | 0.15mm | 0.19mm |

| 25 | 150 | 0.125mm | 0.21mm | 0.28mm |

STANDARD DIMENSIONAL TOLERANCES FOR TOOLING PLATE

| GAUGE TOLERANCES | WIDTH TOLERANCES | LENGTH TOLERANCES | ||||||

| Specified Gauge | Tolerance | Specified Width | Tolerance | Specified Width | Tolerance | |||

| Over | Thru | Over | Thru | Over | Thru | |||

| 6.3 | 19mm | +/-0.25mm | 0 | 250mm | +4.75mm | 0 | 250mm | +4.75mm |

| 19 | 32mm | +/-0.43mm | 250 | 1220mm | +9.50mm | 250 | 1220mm | +9.50mm |

| 32 | 50mm | +/-0.64mm | 1220 | 1825mm | +12.7mm | 1220 | 1825mm | +12.7mm |

| 50 | 75mm | +/-1.25mm | 1825 | 1950mm | +15.9mm | 1825 | 6000mm | +15.9mm |

| 75 | 83mm | +/-1.65mm | - | - | - | - | - | - |

| 83 | 90m | +/-2.00mm | - | - | - | - | - | - |

| 90 | 100mm | +/-2.80mm | - | - | - | - | - | - |

| 100 | 125mm | +/-3.20mm | - | - | - | - | - | - |

| 125 | 150mm | +/-3.40mm | - | - | - | - | - | - |

| 150 | 175mm | +/-3.705mm | - | - | - | - | - | - |

TOOLING PLATES STANDARD METRIC SIZES

| 6.35 x 1250 x 2500mm | 20 x 1500 x 4000mm | 50 x 1500 x 4000mm |

| 6.35 x 1250 x 4000mm | 25 x 1250 x 2500mm | 60 x 1250 x 2500mm |

| 10 x 1250 x 2500mm | 25 x 1250 x 4000mm | 60 x 1250 x 4000mm |

| 10 x 1250 x 4000mm | 25 x 1500 x 4000mm | 60 x 1500 x 4000mm |

| 12.7 x 1250 x 2500mm | 30 x 1250 x 2500mm | 75 x 1250 x 2500mm |

| 12.7 x 1250 x 4000mm | 30 x 1250 x 4000mm | 75 x 1250 x 4000mm |

| 12.7 x 1500 x 4000mm | 30 x 1500 x 4000mm | 75 x 1500 x 4000mm |

| 15 x 1250 x 2500mm | 40 x 1250 x 2500mm | 100 x 1250 x 2000mm |

| 15 x 1250 x 4000mm | 40 x 1250 x 4000mm | 125 x 1250 x 2000mm |

| 15 x 1500 x 4000mm | 40 x 1500 x 4000mm | 150 x 1250 x 1500mm |

| 20 x 1250 x 2500mm | 50 x 1250 x 2500mm | 195x1500x1500mm |

| 20 x 1250 x 4000mm | 50 x 1250 x 4000mm | 350x1100x3000mm |

Other sizes are available subject to enquiry, up to a maximum per plate weight of 1100kg.

Maximum gauge: 350mm; Maximum width 2000mm; Maximum length: 5000mm

Our Advantage

| DAMPING | Absorbs vibration for longer life, while retaining dimensional stability. |

| TOOLING | 4 to 5 times greater tool life. |

| FINISH | Up to 5 times more machinable than rolled aluminum. |

| COSTS | Machine dry, without oil or chemicals. |

| WEIGHT | Easier handling saves energy and time. |

| FLATNESS | Eliminates surface machining. |

| STABILITY | No stress relief after machining; no warps and is dent resistant. |

| WELDING | Strong weldments up to 95% of parent metal, with minimal porosity. |

| ALKALI-RESISTANT | Makes for easy cleaning. |

| CORROSION RESISTANT | A wide variety of chemical treatments exists for corrosion protection, alteration of surface appearance, and to provide a base for painting. Basic engineering precautions averts galvanic corrosion. |

| STRENGTH | Excellent strength and stiffness per unit weight. |

| NON-GALLING | Sound and rugged surface, offering a low coefficient of friction and minimum wear, |

REPID HEAT | Ideal for a broad range of operating temperatures, from 350 degrees Fahrenheit to -30 degrees Fahrenheit. |

| NONMAGNETIC | Good for electrical and computer applications. |

UNIT VOLUME | Greater amount of finished magnesium material obtained, pound for pound. |

| SALVAGE | Scrap retains a consistently high level of value. |