Shenzhen ruiyihang technology co., ltd |

|

High Precision Custom Stainless Steel Metal Products CNC Machining Parts

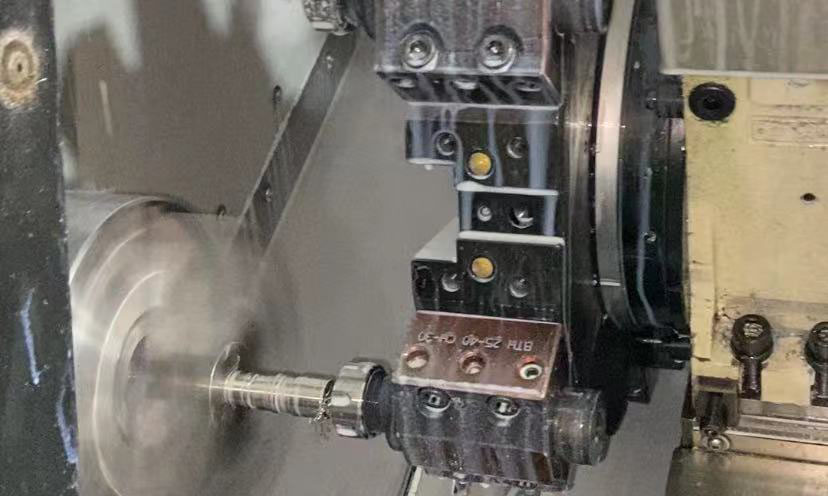

The density of stainless steel is 7.93 g / cm3 and the hardness is ≤ 90hrb. It is a high hardness material. Taking machining stainless steel SS304 as an example, the factory is equipped with 6 large CNC machining centers, such as BF-1165 / 850, which can meet the machining actions of drilling, milling, cutting and other machining of high hardness materials such as steel and stainless steel.

Stainless steel has very good corrosion resistance, heat resistance, high temperature resistance and low temperature resistance. It has become one of the materials often selected by engineers. The common models of stainless steel are SS303, SS304, SS316 and SS420 SS304 and SS316 can reach food grade. Machining stainless steel (SS316) also has good chloride corrosion performance, so it is usually used in marine environment.

Software/format | PRO/E, Auto CAD, Solid works, IGS, UG, CAD/CAM/CAE |

Name | High Precision Custom Stainless Steel Metal Products CNC Machining

Parts |

Tolerance | 0.01~0.05mm, can customize as per request. |

Dimension | Customized |

Test equipment | Measurement instrument, projector, CMM, Altimeter, Micrometer,

Thread Gages, Calipers, Pin guage etc. |

Processing | CNC turning, milling, drilling, auto lathe, tapping, bushing,

surface treatment, anodized, casting ,injection,3D printing,etc. |

Our Advantages | 1.) 24 hours online service & quickly quote/delivery. 2.) 100% QC quality inspection before delivery, can provide quality inspection form. 3.) 15+ years of experience in the CNC machining area and have a

senior design team to offer perfect modification suggestions. |

The thermal conductivity of stainless steel is relatively low, so under the same conditions, the milling temperature of stainless steel is about 100~150 ℃ higher than that of steel. The milling cutter with cemented carbide surface coating is selected.

According to the experience of the factory, the machining of stainless steel is divided into rough machining and finish machining, with a cutting speed of 10 ~ 140m / min; Feed rate: 0.013 ~ 0.15mm/z; At the same time, when milling stainless steel, extreme pressure emulsion or vulcanized cutting oil shall be selected to ensure that the cutting temperature can be reduced rapidly.

Grinding, polishing, sandblasting, passivation, brushing, electroplating, laser logo.