Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment

ceramic parts and components:

1. Great mechanical strength.

2. Good heat resistant.

3. High corrosion resistance

4. Various kinds of shape.

5. Long service life.

Industrial Ceramic Intriduction

Aluminium Oxide, Al2O3 is the most widely applied and cost

effective technical ceramic material. It offers a combination of

superior mechanical strength and electrical properties, wear

resistance and corrosion resistance. The maximum working

temperature is up to 1700 °C with relatively high thermal

conductivity. It is also an electrically insulating material with a

high electrical resistivity. The good corrosion resistance makes it

insoluble in water and slightly soluble in strong acid and alkaline

solution.

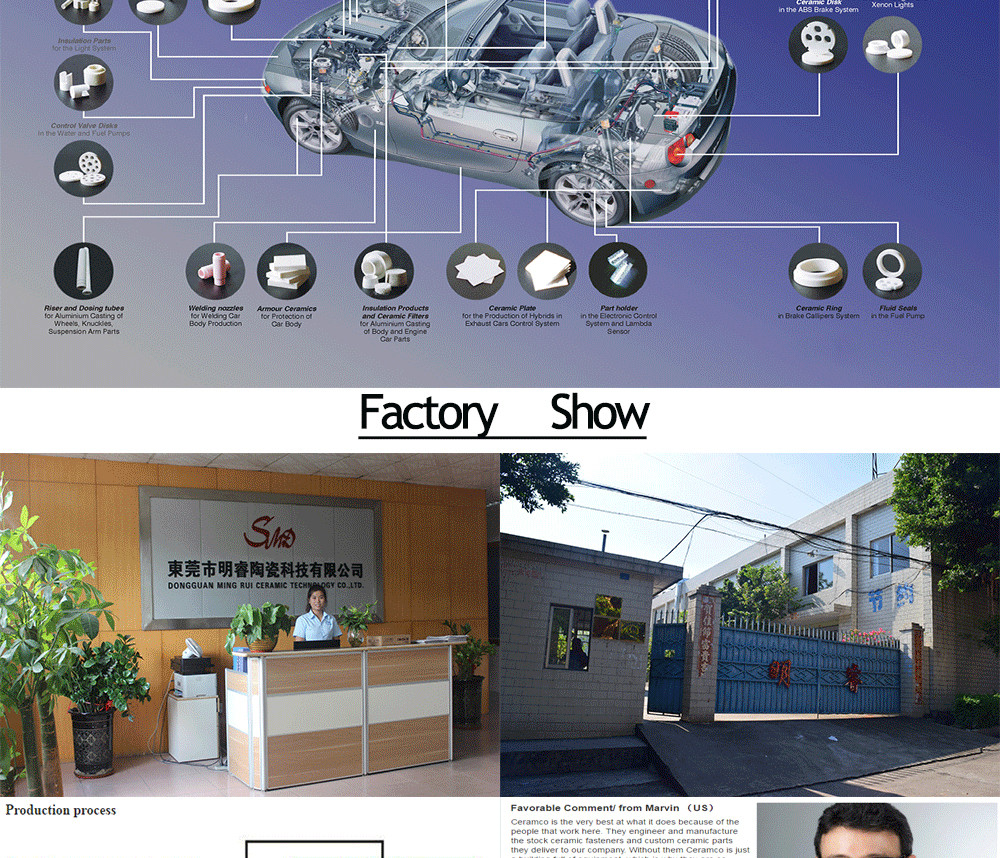

Company Introduction

Mingrui ceramic manufacture and provides alumina ceramic components

for a wide range of application like Mechanical Equipment,

Electronic & Electrical, Oil Drilling, Medical, Chemical

Industry etc. According to actual application and customer's

requirement, the purities vary from 95%-99.7% and the forming

methods will be different. The forming methods applied in our plant

include dry pressing, isostatic pressing, injection moulding,

extrusion moulding. With experienced engineers and talented

workers, we are confident to offer high quality, high precision,

complex components for customers worldwide.

Product Description

Precision Ceramics has years of experience designing and developing technical ceramic solutions for a wide variety of applications and industries.Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment. We offer this expertise to all of our customers to ensure the best design and materials are chosen for their specific application and needs.Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment,Typically, our custom technical ceramic components and parts we supply are used for one of three main reasons:

Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum

Industry Equipment

High temperature ceramics – crucibles, nozzles, lasers,

furnace/kiln fixtures

Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum

Industry Equipment

Wear and corrosion resistant ceramics – plates, housings, gages,

caps/lids

Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum

Industry Equipment

Electrical insulation ceramics – contact blocks, standoffs,

fasteners, spacers

Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment

Precision Ceramics is one of the world’s premiere technical ceramic

suppliers – contact us to see what technical ceramics we can create

for you.

Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium |

High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Anti-chemical Corrosion Ceramic Sandblasting Nozzles Petroleum Industry Equipment |

FAQ

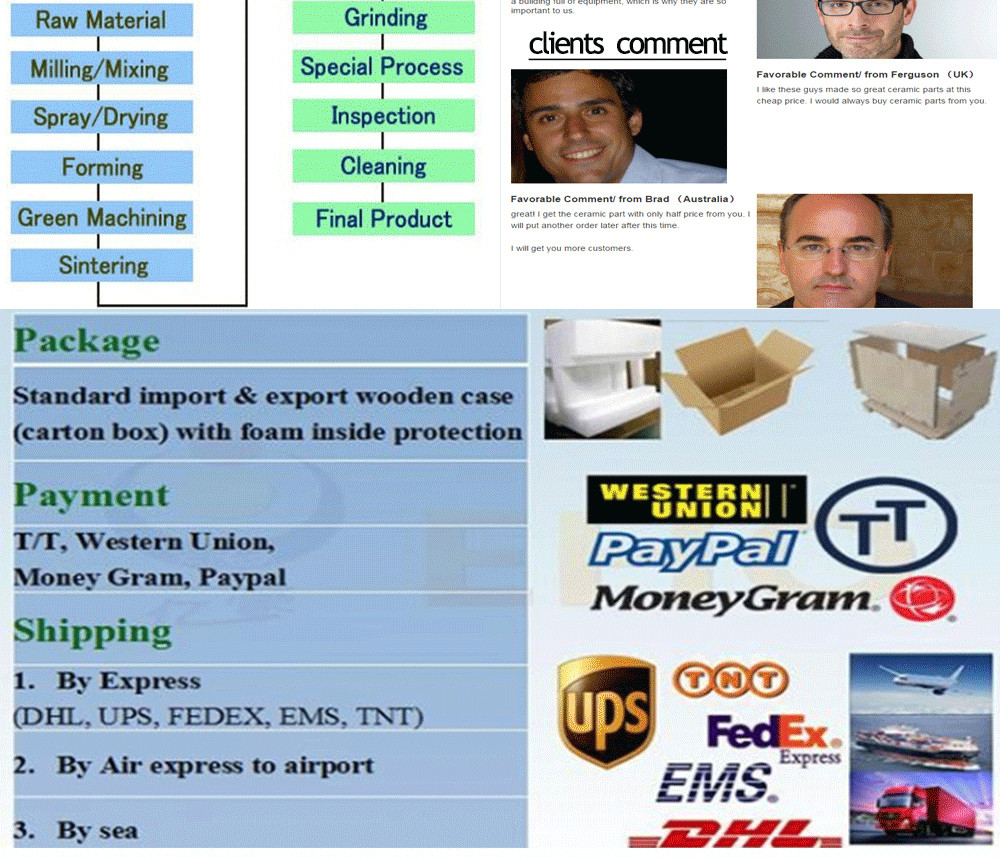

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .