Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

High temperature application Aluminium nitride nozzle ALN Oil Spray Nozzles

Aluminum nitride (AlN) is beginning to replace alumina as a substrate and heat sink for electronic circuits. The thermal conductivity of AlN, about 8 times that of alumina, is the primary reason for its selection in these applications. While beryllium oxide has even higher conductivity, concerns about that material’s toxicity reduce its appeal.

Sand blast nozzles are designed to suit 10 Gallon sandblaster machine. We have designed these nozzles especially for the 10 Gallon sandblaster. Nozzle sizes range 4mm to 7mm for the most efficient results & better sandblast machine operation.

Features

Nozzles are made from ceramic which has been designed for use in sandblast machine. Cone shape nozzle adapts to blast hose fitting provided with sandblaster

Technical Details

SIZES 4, 5, 6, 7 mm - LENGTH 30mm WIDTH 15mm

SUIT SANDBLAST CABINET GUN

MATERIAL CERAMIC

Product Description

Advantages of industrial ceramic AlN nozzles:

1. Refractory.

2. Self Lubricating

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Due to these outstanding properties, Ceramic Products are used in a wide range of industrial and advanced appications.

And a lot of practical applications prove that our ceramic products has reached a state of high standard and quality.

Properties Sheet:

| Properties | Units | 95 Alumina | 99 Alumina | Zirconia |

| Density | ɡ / cm3 | 3.65 | 3.92 | 5.95 - 6.0 |

| Water Absorption | % | 0 | 0 | 0 |

| Coefficient of Thermal Expansion | 10-6 / K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young’s Mod | Gpa | 280 | 340 | 210 |

| Poisson’s Ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness | Mpa | 1400 | 1650 | 1300 - 1365 |

| Flexural Strength @ Room Temperature | Mpa | 280 | 310 | 950 |

| Flexural Strength @ 700℃ | Mpa | 220 | 230 | 210 |

| Compressive Strength@Room Temperature | Mpa | 2000 | 2200 | 2000 |

| Fracture Toughness | Mpa * m½ | 3.8 | 4.2 | 10 |

| Heat Conductivity @ Room Temperature | W / m * k | 18 - 25 | 26 - 30 | 2.0 - 2.2 |

| Electrical Resistivity @ Room Temperature | Ω*mm2 / m | >1015 | >1016 | >1015 |

| Max Application Temperature | ℃ | 1500 | 1750 | 1050 |

| Resistance to Acid Alkaline | / | High | High | High |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV / mm | 16 | 22 | / |

| Thermal Shock Resistance | Δ T ( ℃ ) | 220 | 180 - 200 | 282 - 350 |

| Tensile Strength @ 25℃ | Mpa | 200 | 248 | 252 |

Detailed Images

Wear Resistant Ceramic Sandblasting Nozzles Anti Corrosion ZrO2 Size Customized

Alumina Ceramic Tube / Liner / Sleeve / Cylinder / 99% Al2O3 Nozzle Ceramic Parts

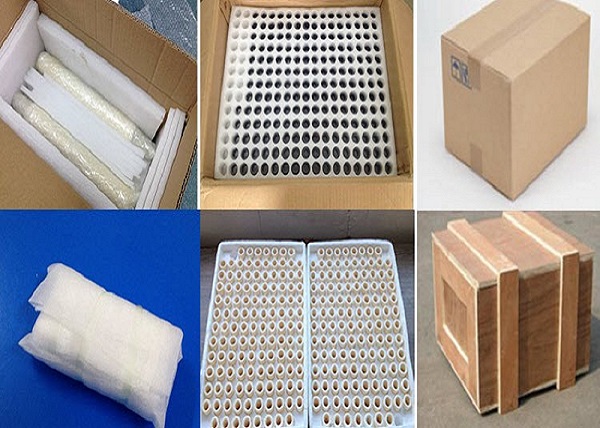

Packaging and Shipping

Heat resistant ceramic nozzle will be wraped in paper first individually, then packed in bubble bags,

finally put in standard export carton packing, or OEM packing..

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or

Sea transportation.

Company information

Who Are We?

Mingrui has yeas of professional OEM experience in manufacturing industrial ceramic parts. We can make the products according to your drawings, custom the size,

thickness and other parameters.

What Do We Do?

We have very advanced technologies in the production of zirconia and alumina ceramic nozzle, rod, ring, tube, shaft, plate, sleeve, valve, plunger, bearing, and semiconductive ceramics etc.. They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace,

even other High-end fields.

Our products with some certificates, such as , CE, TUV, etc..

Factory Show

Production Process Show

One-stop production, from the raw material ( powder ) to final

products, control the quality strickly of every production link.