Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Customized Polished Black Zirconia Sleeve /Cylinder / Liner/Tube

Key words: black zirconia tube / black ceramic

lining

| Product Name | Surface Polished Black Zirconia Tube / Sleeve / Black Ceramic Cylinder |

| Material | zirconia ceramic |

| Color | white ,black, blue or custom |

| Roughness | Ra 0.03 |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | ceramic lining |

Zirconia Sleeve & Zirconia Ceramic Cylinder & Zirconia ceramic liner

(1)In the field of zirconia ceramic, combining the basic theory,

research and application of the material properties and product

usability research, use of technology and results achieved,

zirconia ceramic oil and gas field mining industry demand, zirconia

structural ceramic components promotion and application in the

field of petroleum machinery, successfully replacing the

traditional metal cylinder, the industrialization of high-tech

production.

(2)Zirconia ceramic wear resistance, high temperature resistance,

resistance to corrosion, high strength, high life characteristics

the flexural strength 1200MPa, density 6.0g/cm3; ceramic cylinder

liner in the high-temperature, high-pressure, high-solid

impurities, highly corrosivestable work under adverse conditions

such as media; withstand the pressure more than 50MPa, the service

life of up to 5000 hours (metal cylinder can only reach a few

hundred hours).

(3)Product technology is mature, the leading domestic level, and

completely replace imported; Ceramic Processing dimensional

accuracy, shape, position tolerances and surface finish are

comparable to traditional metal products; domestic and foreign oil

drilling industry has been widely recognized and has a broad

marketprospects.

Company Introduction

Mingrui ceramic manufacture and provides Zirconia ceramic

components for a wide range of application like Mechanical

Equipment, Electronic & Electrical, Oil Drilling, Medical,

Chemical Industry etc. According to actual application and

customer's requirement, the purities vary from 95%-99.7% and the

forming methods will be different. The forming methods applied in

our plant include dry pressing, isostatic pressing, injection

moulding, extrusion moulding. With experienced engineers and

talented workers, we are confident to offer high quality, high

precision, complex components for customers worldwide.

Product Description

black zirconia tube / black ceramic lining

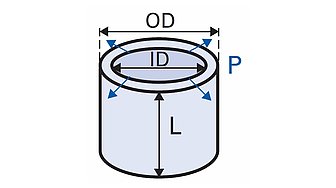

OD Outer diameter

ID Inner diameter

L Length

P Polarization direction

Outer Diameter OD |

|---|

| 2 to 100 mm |

Inner Diameter ID |

| 0.8 to 94 mm |

Length L |

|---|

| max. 200 mm |

Electrodes |

| Inside: Fired Silver (thick film) Outside: Silver (thick film) or PVD thin film (CuNi, Au) |

| Material | Alumina | Zirconia | ||||

| Properties | Units | AL997 | AL995 | AL99 | AL95 | ZrO2 |

| %Alumina | —— | 99.70% | 99.50% | 99.00% | 95% | —— |

| Color | —— | Ivory | Ivory | Ivory | Ivory & White | ivory white |

| Permeability | —— | Gas-tight | Gas-tight | Gas-tight | Gas-tight | Gas-tight |

| Density | g/cm³ | 3.94 | 3.9 | 3.8 | 3.75 | 5.89 |

| Straightness | —— | 1‰ | 1‰ | 1‰ | 1‰ | 1‰ |

| Hardness | Mohs Scale | 9 | 9 | 9 | 8.8 | 8.5 |

| Water Absorption | —— | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | 0 |

| Flexural Strength (Typical 20℃) | Mpa | 375 | 370 | 340 | 304 | 1200 |

| Compressive Strength (Typical 20℃) | Mpa | 2300 | 2300 | 2210 | 1910 | 5700 |

| Coefficient of Thermal Expansion (25℃ to 800℃) | 10-6/℃ | 7.6 | 7.6 | 7.6 | 7.6 | 10 |

| Dielectric Strength (5mm Thickness) | AC-kv/mm | 10 | 10 | 10 | 10 | —— |

| Dielectric Loss 25ºC@1MHz | —— | < 0.0001 | < 0.0001 | 0.0006 | 0.0004 | 0.001 |

| Dielectric Constant | 25º C@1MHz | 9.8 | 9.7 | 9.5 | 9.2 | 29 |

| Thermal Conductivity (25℃) | W/m·K | 35 | 35 | 34 | 20 | 3 |

More photos of ceramic tube/liner/sleeve:

Product show of our factory :

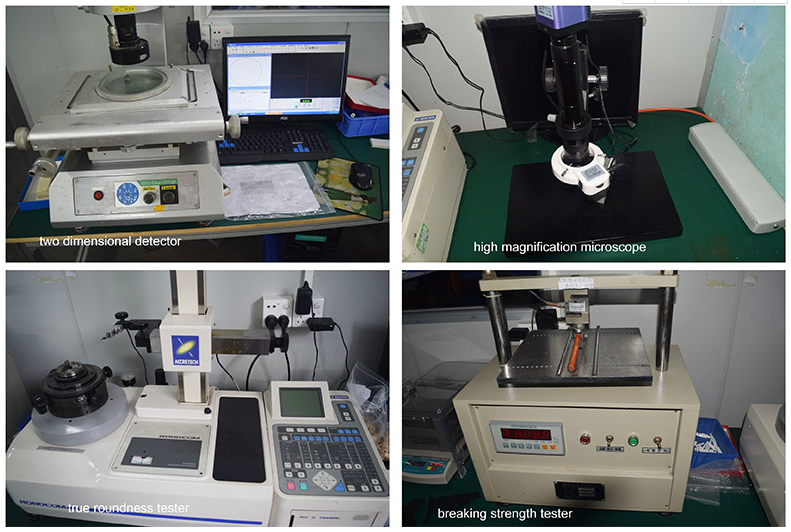

High Precision inspection equipment :

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .