Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Customized zro2 Zirconia Ceramic Textile Tube High Wear Resistance

Zirconia and Alumina Applications:

Product Description

Advantages of ceramic insulator tube:

1. Refractory.

2. Self Lubricating

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Due to these outstanding properties, Ceramic Products are used in a wide range of industrial and advanced appications.

And a lot of practical applications prove that our ceramic products has reached a state of high standard and quality.

Properties Sheet:

| Properties | Units | 95 Alumina | 99 Alumina | Zirconia |

| Density | ɡ / cm3 | 3.65 | 3.92 | 5.95 - 6.0 |

| Water Absorption | % | 0 | 0 | 0 |

| Coefficient of Thermal Expansion | 10-6 / K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young’s Mod | Gpa | 280 | 340 | 210 |

| Poisson’s Ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness | Mpa | 1400 | 1650 | 1300 - 1365 |

| Flexural Strength @ Room Temperature | Mpa | 280 | 310 | 950 |

| Flexural Strength @ 700℃ | Mpa | 220 | 230 | 210 |

| Compressive Strength@Room Temperature | Mpa | 2000 | 2200 | 2000 |

| Fracture Toughness | Mpa * m½ | 3.8 | 4.2 | 10 |

| Heat Conductivity @ Room Temperature | W / m * k | 18 - 25 | 26 - 30 | 2.0 - 2.2 |

| Electrical Resistivity @ Room Temperature | Ω*mm2 / m | >1015 | >1016 | >1015 |

| Max Application Temperature | ℃ | 1500 | 1750 | 1050 |

| Resistance to Acid Alkaline | / | High | High | High |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV / mm | 16 | 22 | / |

| Thermal Shock Resistance | Δ T ( ℃ ) | 220 | 180 - 200 | 282 - 350 |

| Tensile Strength @ 25℃ | Mpa | 200 | 248 | 252 |

Material Service:

Zirconia Ceramic: Mg-PSZ, Y-TZP, ZTA

Alumina Ceramic: 96%, 99%, 99.5% Al2O3

Silicon Nitride: Si3N4, RBSN, SRBSN, GPSN

Machinable Ceramic: Macor Ceramic

Machining Service:

Laser Cutting

CNC Machining

Cernerless Grinding and Inside Hole Honing

Surface Grinding and Polishing

Detailed Images

95 Alumina Ceramic Tube 99% Al2o3 Heat Insulating Parts With High Polished Surface

99% Alumina Ceramic Insulating Tube Empire Tubes Insulation Pipe Bushing Insulator

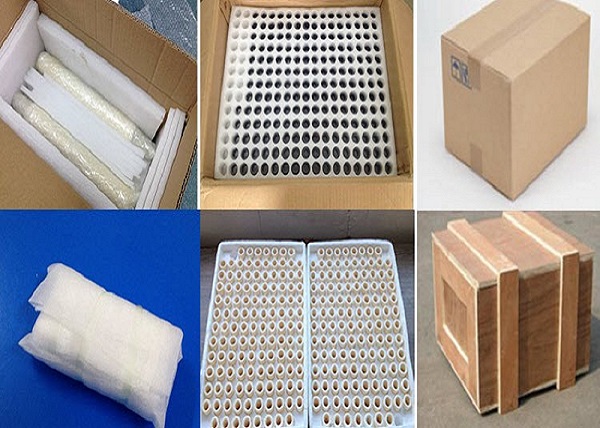

Packaging and Shipping

China Ceramic tubes will be wraped in paper first individually, then packed in bubble bags,

finally put in standard export carton packing, or OEM packing..

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or

Sea transportation.

Company information

Who Are We?

Mingrui has yeas of professional OEM experience in manufacturing industrial ceramic parts. We can make the products according to your drawings, custom the size,

thickness and other parameters.

What Do We Do?

We have very advanced technologies in the production of zirconia and alumina ceramic nozzle, rod, ring, tube, shaft, plate, sleeve, valve, plunger, bearing, and semiconductive ceramics etc.. They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace,

even other High-end fields.

Our products with some certificates, such as , CE, TUV, etc..

Factory Show

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.