Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

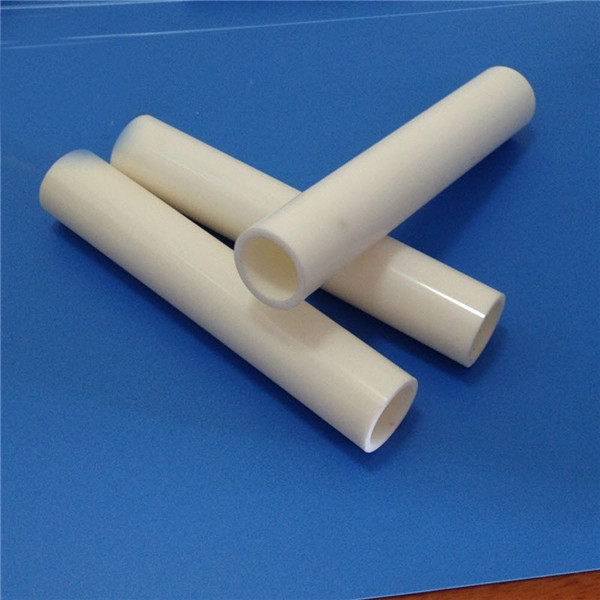

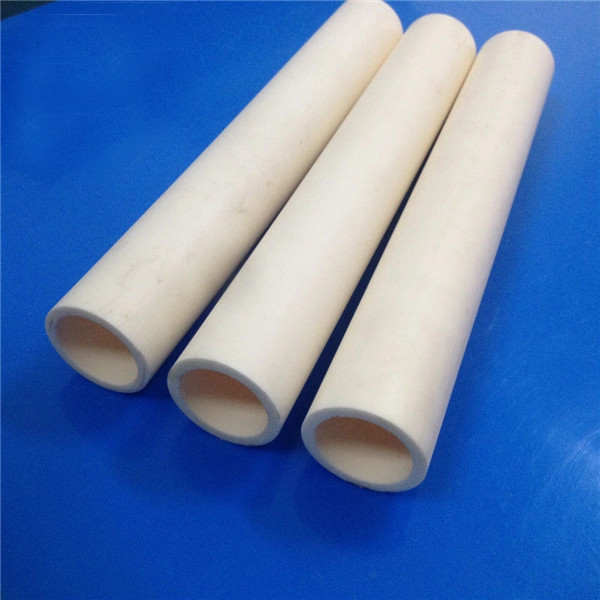

High Purity Alumina Tube, 99.6% Al2O3 Ceramic Tube

High purity alumina tubes can withstand very high temperatures under reducing, inert or high vacuum conditions. They remain good chemical resistance under high temperatures and have excellent wear and abrasion resistance. 99.6% Alumina tube can withstand up to 1800℃.

Our high purity alumina (Al2O3 content > 99%) ceramics are purpose-built to perform across a wide range of high-temperature applications. Our high purity alumina shows considerable resistance to chemical attack due to the lack of glassy phases that tend to determine corrosion resistance.

Alumina tubes can be used in a multitude of applications include:

Turbine casting supports

Surgical devices

Knife sharpeners

Wafer processing components

Ceramic insulators

Vacuum devices

High-power resistor

Thermocouple components

Protection tubes

Igniter tubes

Thermostats

alumina tube

Alumina Tube Features

Alumina purity: 99.6%

Color: Ivory

Sintering temperature: 1810℃

Max. working temperature: 1800℃

Sag Temp. Unsupported Tube: 1600℃

Chemical

Composition

(%) Al2O3 >99.6

SiO2 <0.1

Fe2O3 <0.05

R2O <0.1

Alumina Tube Standard size

OD x ID x Length (mm)

28 x 22 x 200-1500mm 30 x 24 x 200-1500mm

32 x 26 x 200-1500mm 35 x 28 x 200-1500mm

40 x 30 x 200-1500mm 50 x 40 x 200-1500mm

60 x 50 x 200-1500mm 70 x 60 x 200-1500mm

80 x 70 x 200-1500mm 90 x 80 x 200-1500mm

100 x 90 x 200-1500mm 120 x 110 x 200-1500mm

*Other sizes can be produced according to your requirement.

Note: Alumina products are sensitive to thermal shock. Try to warm up the furnace chamber slowly. A heating rate between 150℃~300℃/hour is recommended for the first 1-1.5 hours so that the alumina products can be evenly heated to reduce the impact of thermal shock.

Data Sheet↓

Alumina Ceramic Properties | 96 Alumina Ceramic | 99 Alumina Ceramic | |

| Item | Unit | Typical Values | |

| Physical Properties | |||

| Color | White | Ivory | |

| Density | g/cm3 | 3.7 | 3.85 |

| Alumina Content | % | 96% | 99% |

| Gas permeability | 0 | 0 | |

| Water Absorption | 0 | 0 | |

| Mechanical Properties | |||

| Rockwell Hardness | HRA | 80 | 82 |

| Vickers Hardness (Hv50) | Gpa(Kg/mm²) | 15.7(1600) | 15.7(1600) |

| Flexural Strength(20°C) | Mpa | 300 | 330 |

| Compressive Strength(20°C) | Mpa | 2000 | 2000 |

| Modulus of Elasticity (20°C) | Gpa | 275 | |

| Poisson's Ratio (20°C) | 0.22-0.23 | ||

| Fracture Toughness(20°C) | MPam1/2 | 3.5 | 4 |

| Thermal Properties | |||

| Thermal Conductivity(20°C-400°C) | W(m.K) | 25 | 27.5 |

| Thermal Expansion Coefficient | 10-6/°C | 6.5-7.5 | 7.6 |

| Thermal Shock Resistance | T°C | 200 | 200 |

| Maximum Use Temperature | °C | 1600 | 1650 |

| Electronic Properties | |||

| Dielectric Strength | KV/mm | >12 | >10 |

| Dielectric Constant | Er | 9-10 | 9.1 |

| Dielectric Loss Angle(1MHz) | 0.0002 | 0.0002-0.0003 | |

| Volume Resistivity(20°C) | Ω.cm | >1014 | >1014 |

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.