Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

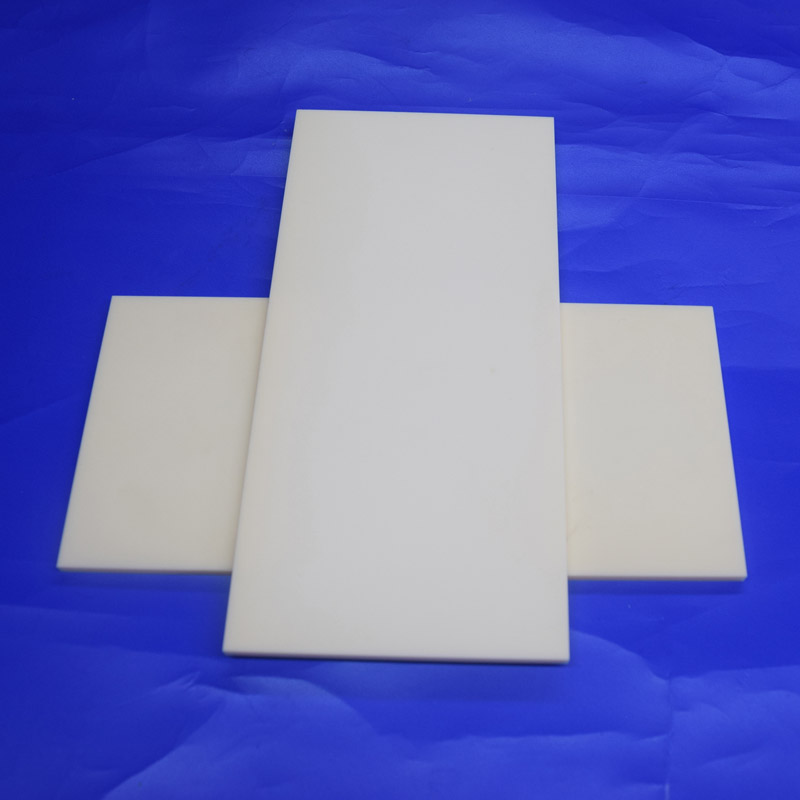

Wear -Resistance 99% Alumina Ceramic Plate/ Rectangular Insulating Board / Square Plate

Advantages of alumina ceramic plate:

1. Refactory.

2. Isostatic Pressed.

3. Long Service Life.

4. Superior Mechanical Strength.

5. High Corrosion and Wear Resistance.

6. High Temperature Resistance.

7. Good Insulation Performance Precision.

8. High Purity Zirconia and Alumina Ceramic Material.

Product Name | High Wear Resistance Electrical Insulation 95% Alumina Precision Ceramic Rods |

Material | Alumina ceramic |

OD | 0.3mm -50mm |

Length | mm - 500mm |

Surface Roughness | Ra0.05 |

Torlerance | +/- 0.001mm |

Lead time | 10 - 30days |

Shipping | Air Express (DHL/UPS/TNT/ FedEx) |

Properties Sheet of zirconia and alumina :

| Properties | Unit | Alumina | Zirconia | ||||

| 96%Al2O3 | 99%Al2O3 | 99.5%Al2O3 | 99.8%Al2O3 | 99.9%Al2O3 | 3Y-TZP | ||

| Colour | - | White | White | Ivory | Ivory | Translucent | white/black |

| Bulk density | g/cc | 3.78 | 3.88 | 3.93 | 3.93 | 3.98 | 6.03 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 | 0 |

| Grain size | μm | 5-10 | 2-5 | 2-5 | 2-5 | 2-4 | 0.4 |

| Bending strength | MPa | 380 | 350 | 360 | 380 | 300 | 1000 |

| KIC | MPa.m1/2 | 3~4 | 4 | 3~4 | 3~4 | 3~4 | 5~8 |

| Vickers Hardness | GPa | 13 | 14 | 14.5 | 14.5 | 15 | 13 |

| Young's Modulus of Elasticity | GPa | 360 | 370 | 370 | 380 | 390 | 200 |

| Thermal Conductivity | W/m° K | 24 | 28 | 32 | 32 | 34 | 2 |

| Coefficient of Linear Expansion | 10-6/°C | 6.7 | 7.2 | 7.2 | 7.2 | 7.2 | 10.5 |

| Dielectric Constant (1MHz) | - | 9.1 | 9.5 | 9.6 | 9.6 | 9.9 | 33 |

| Dielectric Loss Angle (1MHz) | - | 0.0002 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.002 |

| Dielectric Strength | V/m | 15×106 | 15×106 | 15×106 | 15×106 | 15×106 | 11×106 |

| Volume Resistivity | Ohm.cm | >1014 | >1014 | >1014 | >1014 | >1014 | 1013 |

| (RT) | |||||||

Packaging & Delivery

| Packaging Details: | 1. Carton with Bubble bag or foam. 2. Wooden carton 3. As per customer's requirements. |

| Delivery Details: | 1. 3-25 days for sample 2. 25-40 days for mass products. |

| Shipment Terms: | 1. Small order: By express, DHL/ UPS/ Fedex/ EMS etc. 2. Large order: By sea or By air |

A: We are factory.

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: