Guangzhou Ruihe New Material Technology Co., Ltd |

|

Verified Suppliers

|

|

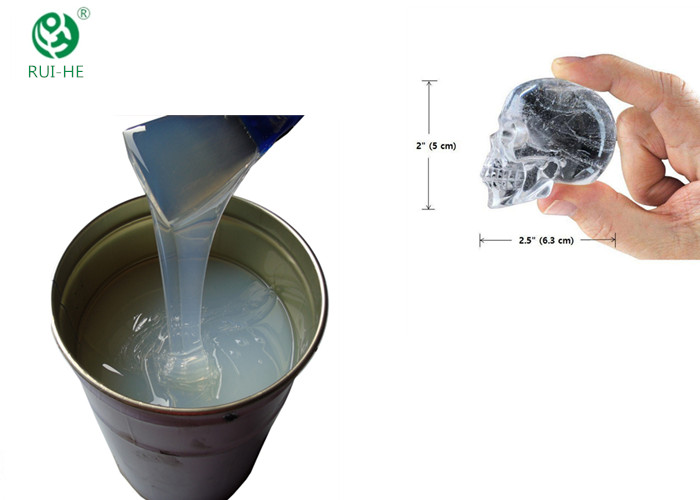

Silicone Ice Cube Tray 100% Food Grade Silicone Rubber With FDA Standard Soft Silicone Mold

Description

Liquid silicone rubbers are pumpable two-part compounds that are

delivered ready to use. They are vulcanized by addition curing.

Component A contains catalyst and component B functional

polysiloxane as curing agent.

Compared to peroxide curing, liquid silicone rubbers do not release

any curing by-products.

| Style NO. | 6250-18 |

| End use | food mold, nipples |

| Curing type | Platinum vulcanization |

| Shelf life | 12 months |

| Payment term | L/C, T/T, Western Union, Paypal |

Typical Property

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

This data is a typical reference value and is for reference only.

FAQ

Q: Why is the silicon mold oily?

A: The molding silicone rubber itself doesn’t contain any oil, so

it won’t be oily. If the mold is oily, it may be because of two

reasons:

Q: In what colors is silicone available?

A: Silicone can be supplied in a very wide range of colors,

including fluorescents, metallics, and even those that change color

with heat!

Q: What equipment do I require to process silicone compound?

A: Silicone rubber compounds can, in general, be processed on

conventional rubber processing machinery.

Instructions

Here is a look at the LSR molding process:

1. LSR A + B components typically come in a 5-gallon pail or 55-gallon drum. A process controlled pumping kit presses down on the buckets to force the material into the static mixer and feed into the injection unit.

2. Then, streams of pigment can be added and controlled. In the injection, press material will be mixed together additionally with a screw and pushed forward to create a “shot” of material, or the amount needed to fill the mold.

3. After the material is injected into the mold, it will then stay clamped together to cure the LSR. Then, either an operator or a robot will remove the cured product from the mold and the cycle repeats. It is a very quick efficient process that typically averages 30 seconds.

Packing & Storage

Available in 20kg pails or 200kg drums.

Store in a cool, dry place out of direct sunlight, use it within 12 months from the day of manufacture.

Why should you choose RUI-HE?