Guangzhou Tianyuan Silicone Machine Technology Co., Ltd. |

|

TYM W5058 Liquid Silicone Rubber Injection Molding Machine For Swimming Googles

TYM Liquid Silicone Rubber Injection Molding Machine foucus on swimming googles production technology for more than 17 years . TYM machine and mold helped more than 40 countries and regions improved their efficiency and quality.

Product Features

A. Newly-optimized integrated all-in-one design.

B. Meet multiple requirements on the automatic manufacturing technique for LSR products.

C. Shorter the mould closing and opening time, improve the production efficiency.

D. Remote control function.

E. Multi-section mould closing and opening and injection, speed adjusting stepless.

| Machine Model | Shot Volume | Injection Rate | Injection Pressure | Clamping Force | Opening Stroke | Tie-Bars Space | Ejection Force | Machine Weight | Motor Power |

| TYM-L5058 | 165g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 500*580MM | 4.3T | 5.3T | 12.1kw |

| TYM-L6068 | 300g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 600*680MM | 4.3T | 5.5T | 12.1kw |

| TYM-W4545 | 165g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 450*450MM | 4.3T | 5.2T | 12.1kw |

| TYM-W5050 | 300g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 500*500MM | 4.3T | 5.3T | 12.1kw |

About TYM

Guangzhou Tianyuan Silicone Machine Technology Co., Ltd. is established in 2002, which specializes in designing and manufacturing the LSR automatic injection molding machine as well as the LSR mold, we mastered the core technology, the quality is excellent! Our production technology is in the leading level in China; we adopt the advanced integration design on our LSR machine, and can supply personalized solutions for the customer. It is more energy-efficient, easy to operate, the production speed is high. TYM LSR machine is your best choice for saving the production cost when you choose a machine.

In order to meet customers needs , the mold workshop was built in 2008. We have high-speed precision carving machines (rotation rate is over 36 thousand revolutions, the precision is 3u ) ,mirror spark machines, CNC machine . In terms of quality , we have Sirui second dimension, third dimension testing equipment to Ensure the production accuracy of the mold .

This is our 16 cavities baby nipple mold

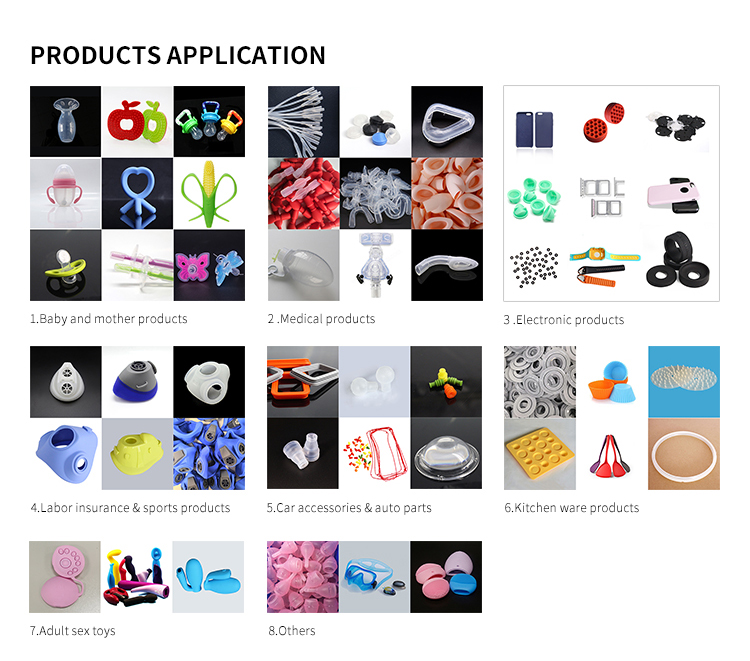

Applications

Our LSR injection molding machine is widely used in medical industry, food industry, infant industry, diving industry, insulator industry and other LSR production field. Furthermore, with abundant technical strength,Tianyuan can design the LSR injection molding equipment exactly based on the customer's requirements, and can provide the turn-key solutions, such as the LSR feeding machine, LSR injection molding machine, LSR mixing system, color adding system, LSR mould and so on.

Certificate

TYM have More than 60 patents , 12 invention patents, it is rated as a national high-tech enterprise in 2013 .

Our Services

Pre-sale service

According to customer's investment budget, plant planning and other forms of pre-sales services to ensure customer's planning is reasonable, standardized and cost-saving and provide matched mold scheme and recommend suitable machine according to customer's product.

On-purchase service

Enable the relevant personnel to be familiar with the operation of the TYM's machinery and understanding the machine maintenance.

1) Installation of LSR machine and new machine commissioning service

2) Machine operator training

3) Training of relevant technicians

After-sales service

1) Free training till relevant personnel is able to operate and maintain independently

2) Help to solve and reply technical problem and question timely, TYM will arrange professional engineer for site instruction

3) TYM will provide technical guidance for free if customer need new equipment or expand(rebuild)

4) TYM will give priority to customer according to customer's upgraded demand when TYM's equipment is upgraded.