Guangzhou Tianyuan Silicone Machine Technology Co., Ltd. |

|

Cost Saving Unique Design Rubber Injection Moulding Machine For Medical Catheter

Tianyuan company is a qualified provider of complete solutions for medical products including medical catheter ,laryngeal airway mask , negative pressure balloon...

TYM professionally rubber injection moulding machine only have one control panel computer , more efficient , more energy efficient , save more production cost. Match with TYM color slurry pump , computer control color slurry input , accuracy up to 0.01G, very easy to operate .

1. Liquid silica gel is a kind of food grade material with high transparency and safety, which is in liquid state and has fluidity. When forming, it does not add auxiliary materials such as sulfurizer, and it is sealed and fed.

2. Solid silica gel is a kind of transparent environmental protection material, which is in solid state and has no fluidity. When forming, it needs to add curing agent to speed up the curing forming time, and open die feeding is required to form.

| Machine Model | Shot Volume | Injection Rate | Injection Pressure | Clamping Force | Opening Stroke | Tie-Bars Space | Ejection Force | Machine Weight | Motor Power |

| TYM-L5058 | 165g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 500*580MM | 4.3T | 5.3T | 12.1kw |

| TYM-L6068 | 300g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 600*680MM | 4.3T | 5.5T | 12.1kw |

| TYM-W4545 | 165g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 450*450MM | 4.3T | 5.2T | 12.1kw |

| TYM-W5050 | 300g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 500*500MM | 4.3T | 5.3T | 12.1kw |

1. Liquid silica gel is generally used in baby products, kitchen products and medical supplies. It can directly contact with food and human body.

2. Solid silica gel is generally used in daily necessities, industrial sundries and auto parts.

3. Safety of liquid silica gel and solid silica gel: liquid silica gel is a food grade material with high transparency and safety. No auxiliary materials such as curing agent are added during molding, and it is sealed and fed for molding. The solid silica gel is a transparent material, which needs to be vulcanized to speed up the vulcanization molding time, and the open die is fed for molding.

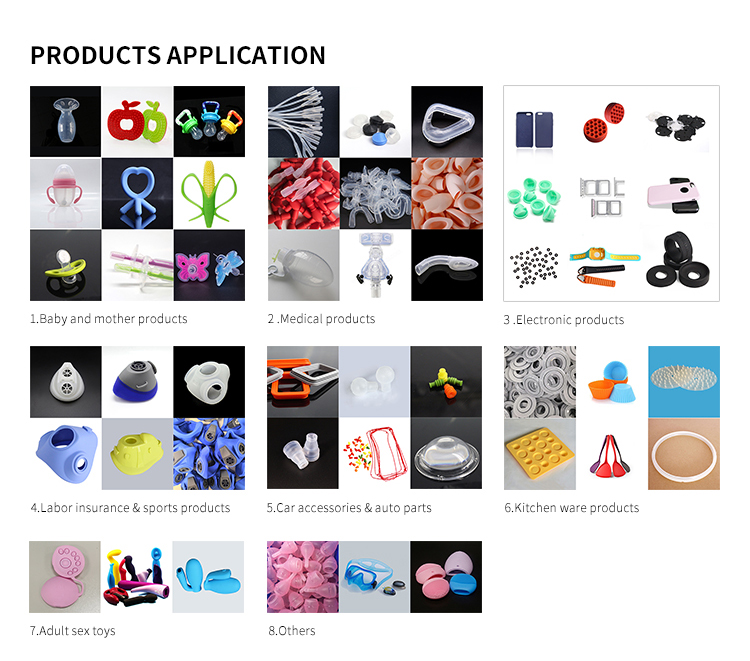

Applications

Our LSR injection molding machine is widely used in medical industry, food industry, infant industry, diving industry, insulator industry and other LSR production field. Furthermore, with abundant technical strength,Tianyuan can design the LSR injection molding equipment exactly based on the customer's requirements, and can provide the turn-key solutions, such as the LSR feeding machine, LSR injection molding machine, LSR mixing system, color adding system, LSR mould and so on.

Certificate

TYM have More than 60 patents , 12 invention patents, it is rated as a national high-tech enterprise in 2013 .

Our Services

Pre-sale service

According to customer's investment budget, plant planning and other forms of pre-sales services to ensure customer's planning is reasonable, standardized and cost-saving and provide matched mold scheme and recommend suitable machine according to customer's product.

On-purchase service

Enable the relevant personnel to be familiar with the operation of the TYM's machinery and understanding the machine maintenance.

1) Installation of LSR machine and new machine commissioning service

2) Machine operator training

3) Training of relevant technicians

After-sales service

1) Free training till relevant personnel is able to operate and maintain independently

2) Help to solve and reply technical problem and question timely, TYM will arrange professional engineer for site instruction

3) TYM will provide technical guidance for free if customer need new equipment or expand(rebuild)

4) TYM will give priority to customer according to customer's upgraded demand when TYM's equipment is upgraded.