Suzhou Lingyao Pharmaceutical Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Advanced lingyao LYAPL1-20 ampoule filling line with High Intelligence

The advantages of the PLC central control, frequency converter, and touch control technology used in the bottle filling and sealing production line lie in their ability to enhance automation, improve operational efficiency, and provide real-time monitoring and control of the production process. These technologies offer greater flexibility, precision, and reliability in managing the production line, leading to increased productivity and reduced downtime. Additionally, the integration of PLC, frequency converter, and touch control technologies allows for seamless communication and coordination between different components of the production line, resulting in optimized performance and streamlined operations.

A Pharmaceutical ampoule filling line is a production line specifically designed for filling pharmaceutical products, such as liquid medications, vaccines, or other solutions, into ampoules. An ampoule is a small sealed vial made of glass that is used to contain a single dose of a medication or solution.

The pharmaceutical ampoule filling line typically consists of several key components, including:

The pharmaceutical ampoule filling line is crucial for pharmaceutical companies to efficiently and accurately fill ampoules with medications while maintaining high quality and safety standards.

| technical parameters | ||||

| product model | LYQCL100+LYASMR 620/43+LYAGF8 | |||

| size range | 1-20ml national standard ampoules | |||

| Output(1-2ml) | 16000-22000pcs/h | |||

| Output(5-10ml) | 8000-12000pcs/h | |||

| Output(20ml) | 5000-7000pcs/h | |||

| Clarity | >99% | |||

| Breakage rate | ≤1%(whole line) | |||

| Filling Precision | ±0.5-2%(according to pharmacopoeia standard) | |||

| Water Consumption and Pressure | 0.2-0.4Mpa / 0.6-1.0m³/h | |||

| Cleaning CA Consumption and Pressure | 0.3-0.6Mpa / 35-80m³/h 0.3-1.0Mpa / 35-80m³/h | |||

| Sealed gas | Gas(liquefied gas)+oxygen, oxyhydrogen generation gas, natural gas | |||

| Oxygen consumption | 0.2-0.3Mpa,1.2-1.5m³/h | |||

| Gas consumption | 0.1-0.3Mpa,1.5-2.5m³/h | |||

| Exhaust volume | 3500-4100m³/h | |||

| Net weight | 7800(kg) | |||

| Total power | around 72kw 380V 50HZ | |||

| Outline size | around 9940x2260x2445mm | |||

Performance Features

◆ Vertical Ultrasonic Bottle Washer: The machine adopts a

combination of ultrasonic online cleaning and separate alternating

water and air jet cleaning, making it the most popular and

effective cleaning equipment internationally with excellent visible

foreign matter detection. It has a wide adaptability and low bottle

breakage rate. Throughout the entire cleaning process, water and

air are sprayed independently through separate nozzles, with each

nozzle fixed for a specific cleaning medium to complete a rinsing

or cleaning process, thus avoiding cross-contamination and dead

corners, in compliance with the requirements of the new version of

GMP.

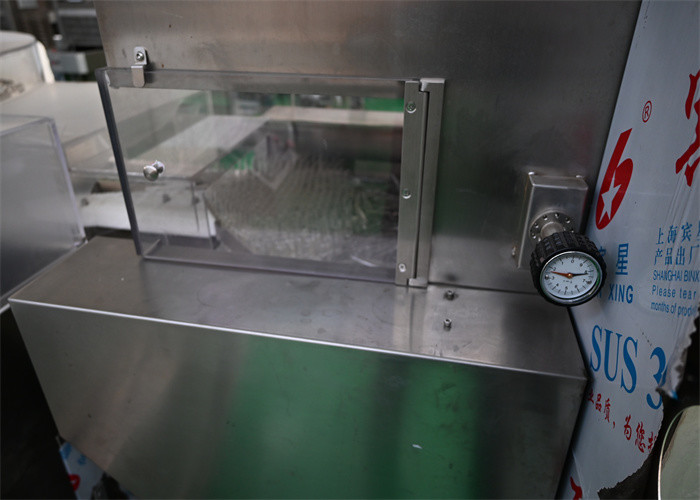

◆ Tunnel-Type Hot Air Circulating Sterilizing Oven: The oven utilizes laminar flow principles and high-speed hot air sterilization process, allowing containers to achieve A-grade standard laminar flow environment within the sealed tunnel for the complete production process of preheating, drying sterilization, and cooling until the bottles are discharged. It is currently the most popular and effective drying and sterilization equipment internationally, with uniform heat distribution, excellent heat removal effect, and equipped with mesh belt ultrasonic online cleaning, power failure protection, and automatic wind pressure adjustment system.

◆ Vertical Ampoule Filling and Sealing Machine: The machine adopts a balcony-type design structure, and the screw turntable bottle transfer can automatically complete bottle separation, pre-flushing with nitrogen, filling, post-nitrogen filling, preheating, and sealing by pulling. It operates smoothly with a high pass rate for finished products.

◆ The entire line adopts advanced intelligent electrical control technology and a simple and intuitive human-machine interface, achieving electromechanical integration design. It can realize both front and rear linkage control and standalone operation, ensuring the normal operation of the entire line. It can display the machine's operating status and fault display, self-diagnosis of faults, fault analysis, and elimination methods, enabling the entire production process to achieve automated control.

Q&A for ampoule filling line

Q:What is an ampoule filling line used for?

A:An ampoule filling line is used for filling pharmaceutical products, such as liquid medications, vaccines, or solutions, into glass ampoules.

Q:What are the key components of an ampoule filling line?

A:The key components of an ampoule filling line include an ampoule washing machine, ampoule filling machine, ampoule sealing machine, inspection system, and labeling/packaging equipment.

Q:How does an ampoule washing machine contribute to the filling process?

A:The ampoule washing machine cleans and sterilizes the glass ampoules before filling to ensure product purity and cleanliness.