Dongguan Pengfei Electronic Technology Co., Ltd. |

|

OEM Zinc Alloy Perfume Caps Electroplating Frosted Free Design

Provides Samples

What do you call the top of a perfume bottle?

Types

Closures can be of three types — screw-on, crimp, and press-on.

Caps

If you use a cap to seal your bottle it will be a screw-on. To use

the fragrance your customer must unscrew the cap; to seal it, he or

she screws the cap back on again. If you used any other type of cap

— such as a cap for a soda bottle, once you uncapped the bottle you

wouldn't be able to get the cap back on again — you would have to

use the whole bottle of perfume or cologne without being able to

reseal it!

Screw-on pumps

Like caps, fine mist spray pumps can also be obtained with a

screw-on thread. These are commonly used for short runs where the

assembly work is being done by hand. Anyone can screw a pump onto a

bottle if both are threaded. You don't need a machine to do it.

Crimp-style pumps

For a number of years crimp-stye pumps have been the standard for

commercial fragrances being produced in quantity. The pump fits

over the neck of the bottle and is then crimped — by machine —

around a ridge in the bottle's neck.

Purchased in bulk, crimp-style pumps can be considerably cheaper than threaded (screw-on) pumps. It the early days of crimp-style pumps, — fifty or more years ago — the crimped part of the pump could look ugly. Today they look fine. Upscale marketers frequently put a collar around the crimped area of the pump so it doesn't even show.

Crimp-style pumps are generally attached to bottles by machines that fill the bottle, set the pump in place, and then crimp it to the bottle, all automatically. An operator may feed bottles to the machine as the bottles are glass — and breakable — and (unless buying by the ton) generally come packed in boxes that, themselves, do not allow automatic feeding.

Manual crimping machines do exist. They are sometimes called

"laboratory models." They are not cheap and they are not perfect.

In using them a certain number of bottles may be broken. But it is

worth being aware that large, automated machines are not the only

tools that can be used to attach crimp-style pumps to bottles.

Press-on style pumps

The same machines that crimp sprays to bottles can also press on

"press-on" style pumps. The action of the machine is similar but,

for the press-on pump, the "inward" motion is eliminated and the

pump is attached by a simple downward thrust.

From your point of view all that matters it that is it is generally

done automatically, by machine, and your filling house will have a

machine to do it.

Finish

"Finish" refers to the neck configuration of bottles and their

matching closures. Trade associations have set standards for sizes

but not all manufacturers adhere to them. Today sourcing for

bottles and closures is global and when buying either bottles or

closures, it is important to review samples — or buy both bottle

and closure from the same distributor — to insure a secure fit.

Threaded sizes

Bottles with threaded necks — also referred to as "screw neck" or

"continuous threaded neck" — require closures with matching thread

sizes.

Threaded finishes are referred to by two numbers, the first indicating the outer diameter of the bottle's neck in millimeters; the second, the thread configuration. Thread configuration is based on how many times the threads pass one another.

Common finishes for threaded bottles and closures would include

13/415 (13mm, 2 thread turns), 15/415 (15mm, 2 thread turns),

20/415 (2mm, 2 thread turns), 24/400 (24mm, 1 thread turn.)

Crimp and press-on

Bottles and closures for crimp and press-on style closures are

defined by a single number indicating the outer diameter of the

bottle's neck at its widest point in millimeters. The closure will

fit over this rim and lock under it. Common sizes for perfume

bottles using a crimp or press-on closure include 13mm, 17mm, 18mm,

and 20mm.

Material

Zinc alloy is an alloy composed of other elements based on zinc.

The alloying elements that are often added are aluminum, copper,

magnesium, cadmium, lead, and titanium. Zinc alloy has low melting

point, good fluidity, easy fusion welding, brazing and plastic

processing, corrosion resistance in the atmosphere, easy recycling

and remelting of residual waste, but low creep strength, prone to

dimensional changes caused by natural aging. Prepared by melting,

die casting or pressure processing.

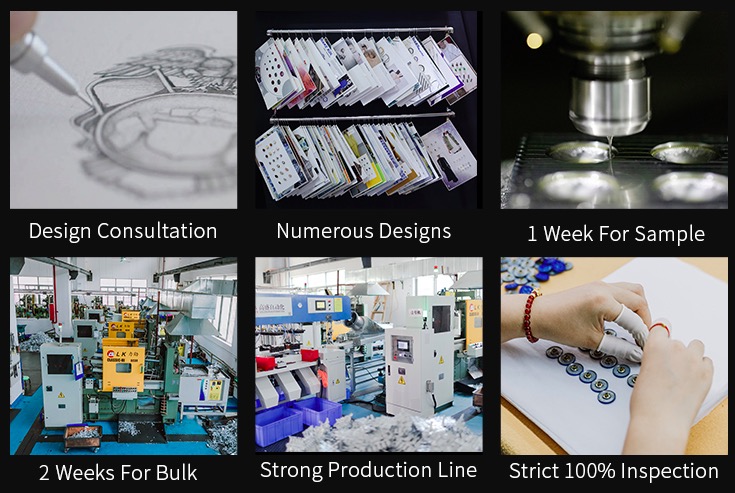

OEM / ODM Custom zamac perfume caps.

* 3 core values: Eco-friendly, High Quality and Sustainable

products.

* 100% self-check rate for production.

* 3-7 working days for free sample.

* 15-45 days for mass production.

* Regular products in bulk stock.

*Production capacity: more than 2000,000 pieces products each

month.

*Contact us for free samples

| Item name | Custom Zinc Alloy Perfume Caps Crown Model Free Design Provides Samples |

| specification | 25*51mm |

| Color | Color can be customized |

| Mold fee | More than 5,000 free mold fees |

| Weight (g) | 82g |

| Material | Eco-friendly Zinc Alloy,Zamac , Zamak |

| Customized design | over 5000pcs,No mould fee charge for simple design. below 5000pcs,Mould fee only $200 for simple design. |

| Free Design | If customized design,Customers only need to offer design idea,We will finish 3D design with 5-7hours |

The products shown are all designed by other customers to show what we can produce. Thank you for understanding that we do not make exactly the same products.

The price is estimated price, because we provide customized

products, please contact us to confirm your customized requirements

and get the accurate prices before placing an order.

Other products

1. Perfume bottle cap

2. Perfume bottle with flower cap

3 .Zinc Alloy Perfume Caps

We got business partners in more than 20 countries, Especially in

America, Canada, Australia, Malaysia, Europe, UK and so on. Every

step of the manufacturing process is inspected by a floor manager

and a final evaluation is completed prior to your pick, pack, and

shipment.

Why Choose Us?

We provide whole process accessories solution from design,

sampling, production to shipping.