Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Servo Guiding Device PLC Control Solar Strut Roll Forming Machine Hydraulic Cut

1. Technical Parameter

Forming thickness: 1.5-2.5mm,galvanized coils yield strength≤G250MPa

Working speed: 5M/min(not include cutting and punching stop time)

Hydraulic punching device: 1 set

Roller stations: about 16 station main roller

Levelling device: 7 roller levelling

Material of roller: bearing steel, quenching treatment.

Material of main shaft: 45# fine steel,

Diameter of main axis: 75mm

Main motor power: 7.5kW

Motor power of hydraulic station: 4KW

Hydraulic station pressure: 12MPa

Electric control system: whole line adopted PLC control, Panasonic PLC

Cutting type: hydraulic drive, cut after forming

Material of cutting blade: Cr12 , quenching process

Roll station: 13 stations

2. Main Components

| Serial No. | Commodity & Description | Quantity |

| 1 | 5T manual uncoiler | 1 set |

| 2 | Leveing guiding | 1 set |

| 3 | Servo feeding device | 1 set |

| 4 | Main roll forming machine | 1 set |

| 5 | Punching Device | 1 set |

| 6 | Cutting device | 1 set |

| 7 | Finished products tabel | 1 set |

| 8 | PLC control system | 1sets |

| 9 | Out tables | 1 sets |

| 10 | Spare parts | 1 sets |

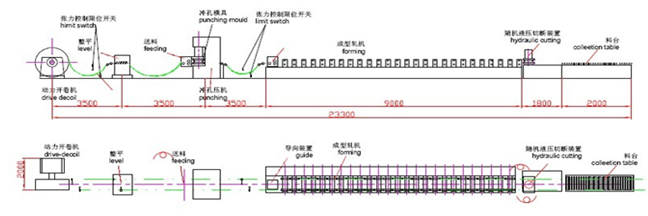

3. Working Flow of Roll Forming Machine

Uncoiling—Feeding&Leveling--Punching Device---Roll forming—Cutting—Products collecting

4. Our advantage:

(1) This production line is high performance-------It's suitable for the various size product

(2) New design----------New developed automatic for different type ceiling t grid.

(3) Roll forming machine is perfect------------Can use 10 years or longer

(4) Length control----------NC control with the sensor

(4) Price --------------it is reasonable (welcome you send mail for asking the price)

(5) Technic support------------10 years technican give you strong and timely support.

5. After-sell service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you install and debug the machines well. Buyer should pay $60 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t forced by human are excluded).

C. Training

During installation and adjustment of the equipment, our engineers shall provide the training to

buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Lifetime services

Life time services to every customer.