Jiangsu Lebron Machinery Technology Co., Ltd. |

|

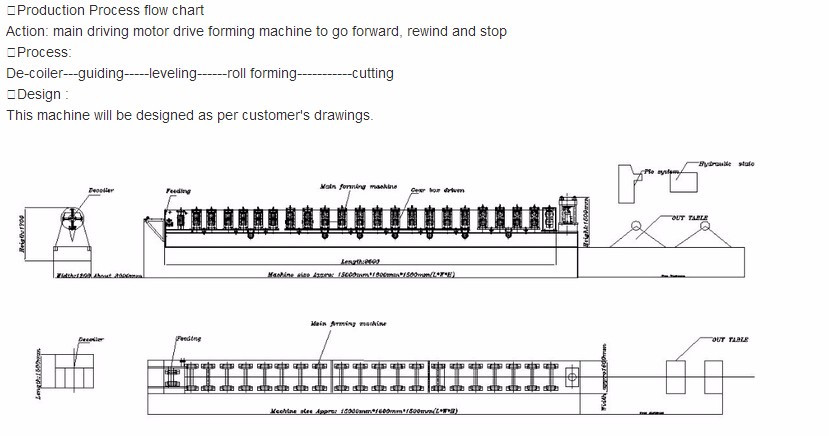

1. Description of C purlin roll forming machine:

C,Z,U shape purlin. Uses the steel strip as the raw material, by the processes such as Leveling, Rolling, Punching, standard length Cutting, etc. become the final product. It can be used for the major stress structure of the large and middle sized industrial constructions and civilian constructions. The roof load bearing and wall panel supporting of the plants, warehouses, engine houses, hangars, exhibition halls, cinemas, gymnasiums, fair flower stands, etc.

LBM factory is manufacturing high quality C shape purlin roll forming machines, and exported to the foreign countries such as Australia, India, Uzbekistan, Indonesia, Croatia, Thailand, etc.

2. Technical details of c purlin roll forming machine:

| Machine Specifications | |

| Weight | About 9000kgs |

| Size | About 10m x 1.4m x 1.8m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 1.5-3.0mm |

| Coil width | According to products size |

| Yield strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 14-16 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 10-15m/min |

| Production Speed | 4-6m/min |

| Forming rollers material | Gcr15 mould steel, with quenched treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric power requirement | Main motor power: 15kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customers requirement |

3. C purlin roll forming machine

4. C purlin roll forming machine

5. Main component of C purlin roll forming machine:

1. Decoiler

3T manual decoiler | |

| Dimensions | 1700mm*1000mm*800mm |

| Width of feeding | 300mm |

| Capability | 3 Ton |

| Bound of expand &fight | 420mm—510mm |

| Mode of expand &fight | inner expand &fight by manual |

| Way of feeding | manual |

| Quantity | 1 |

2. Feeding

Feeding | |

| Entrance table-guide | adjustable |

| Entrance width | about 80mm(according the final design) |

| Entrance and guide roller | diameter is ¢56mm, material is sae1045, surface with chrome |

| Quantity | 1 |

3. Forming

Forming Section | |||

| Profile steel thickness | 0.4-0.7mm GI sheet | ||

| Main motor power | 4kw, AC motor, side motor to save space (Brand: Guomao which made in China) | ||

| Machine Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase | ||

| Roll station | about 8stations +1 station of rectify (according the final design) | ||

| Roller material | SAE1045, hardness and chrome plated surface | ||

| Shaft diameter | ¢56mm material: SAE1045 | ||

| Machine roll forming speed | 0-15m/min (not including punching and cutting time) | ||

| Machine structure | adopt wall panel which is much stronger | ||

| Transmission | by chain, 1.0inch | ||

Post cutting system | |

| Cutting power by hydraulic | 3KW |

| Working pressure | 12Mpa adjustable |

| Cutting after forming | Cut the sheet after roll forming to required length |

| Material of blade | Cr12, 58-62 HRC hardness |

| Length measuring | Automatic encoder length measuring |

| Brand | Omron |

| Tolerance of length | +/- 1.5mm for each piece end product |

5. Out Table

out-table | |

| Size | about 2.0m long*0.3mwide*0.9mhigh |

| Supporter roller | ASTM 1045 with chrome |

| Diameter of rollers | 55mm |

| One out table with support roller | |

| Quantity | 2 units |

6. Hydraulic Station

Hydraulic station | |

| Hydraulic power | 3kw |

| Working pressure | 12Mpa adjustable |

| Solenoid valve | 1 group |

| Hydraulic oil | 46# hydraulic oil |

| Quantity | 1 |

7. Control Desk

Control desk | |

| Operating system language | English and Chinese |

| Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

| Control panel | Button-type switch and touch screen |

| Unit of length | millimeter (switched on the control panel) |

| PLC brand | Panasonic |

| Frequency converter brand | Yaskawa |

| Touch screen | Taiwan Weinview |

6. Our service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you install and debug the machines well. Buyer should pay $60 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t forced by human are excluded).

C. Training

During installation and adjustment of the equipment, our engineers shall provide the training to

buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Lifetime services

Life time services to every customer.

7. Delivery