Shanghai HD M&E Tech Co., Ltd. |

|

Verified Suppliers

|

|

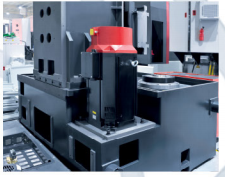

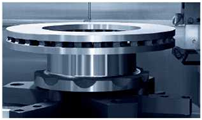

Supplier high precision V4C/V4S Vertical CNC Lathe

Product Introduction

Perfect unity of high processing performance and small floor space, suitable for processing of auto parts such as hubs, brake discs, flywheels etc. and soft and hard turning of bearings, the turning instead of grinding could be realized. The double tools for up and down surfaces of brake disks turning could be realized at the same time in the case that the auxiliary shaft is equipped, improving the processing efficiency and precision level extremely.

Main Technical parameters

| Items | Unit | V4C | V4S | ||

| Maximum swing diameter | mm | Ø600 | Ø720 | ||

| Maximun cutting height | mm | 500 | 690 | ||

| Maximum cutting diameter | mm | Ø500 | Ø600 | ||

| Spindle nose form | A2-8 | A2-11 | |||

| Spindle speed range | r/min | 50-2400 | 50-1000 | ||

| main motor output | Kw | 15/18.5 | 18.5/26 | ||

| max.output torque of spindle | Nm | 549β motor/716α motor | 1113 | ||

| chuck diameter | inch | 12'' | 15'' | ||

| X-axis rapid traverse speed | m/min | 18 | 18 | ||

| Z-axis rapid traverse speed | m/min | 18 | 18 | ||

| X-axis stroke | mm | 300 | 300 | ||

| Z-axis stroke | mm | 500 | 650 | ||

| Torret type | Horizontal 8 station | Horizontal 8 station | |||

| Tool size | mm | 25x25/Ø40 | 25x25/Ø40 | ||

| Machining Accuracy | IT6 | IT6 | |||

| workpiece surface roughness | μm | Ra1.6 | Ra1.6 | ||

| Positioning accuracy | X axis | mm | 0.008 | 0.008 | |

| Z axis | mm | 0.008 | 0.008 | ||

| Repeat position accuracy | X axis | mm | 0.005 | 0.005 | |

| Z axis | mm | 0.005 | 0.005 | ||

| Max.load Disc type(including chucks and clamps) | kg | 350 | 400 | ||

| Machine weight | main body | kg | 6000 | 7500 | |

| Overall dimensions | Length × width × height | mm | 3220x1780x2880 | 3220x1780x3060 | |

Machine Advantage

1.Large stroke and large cutting range

| V2C | V2S | V4C | V4S | V6C | V6S | |

| Max. swing diameter | Ø430 | Ø500 | Ø600 | Ø720 | Ø860 | Ø1000 |

| Max. turning diameter | Ø280 | Ø330 | Ø500 | Ø600 | Ø800 | Ø900 |

FANUC function enhancement

Spindle accuracy ↗ 55% Max. RPM of spindle ↗ 11%

Max. turning diameter ↗ 14% Max. turning diameter ↗ 10%

Rapid traverse of X axis ↗ 100% Rapid traverse of Z axis ↗ 33%

Positioning accuracy of X axis ↗ 33% Positioning accuracy of Z axis ↗ 25%

Independent waterfall-type chip flushing mechanism

Large exhaust port for centralized processing of iron chip and cutting fluid

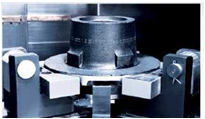

2.Optimized core structure

Provide different processability, form and layout of cutters to ensure perfect cutting effect.

Feeding system: driven by servo motor, X axis and Z axis are directly connected with the ball screw through flexible coupling. The ball screw is installed with one end for fixing and the other end for support to avoid screw elongation due to the temperature rise in operation which may cause longitudinal deformation and achieve high rigidity, high speed, high durability and long life.

Main transmission structure: the main motor can be placed directly on the lathe body, which can provide better processing rigidity.

| Various cutting conveyor belts | |||||

| Chain type | Scraper type | Magnetic scraper | Double chain type | ||

| machining materials | Steel, copper, aluminum, carbon and other metal and non meta | Aluminum, cast iron, etc. | Steel, cast iron | Steel, carbon, and other metal and nonmetal |

| Rear chip removal | Operating environment | Applicable to all kinds of chips such as rolls, lumps, and blocks | Applicable for continuous conveying of breakers and chips | Applicable for conveying of steel and cast iron with chips a length of less than 150 mm in wet processing | Applicable for conveying of lump metal or non-metal that is difficult to be discharged by ordinary chain type chip conveyor and to the situation of large amount of chips |

| Nitrogen balance system minimizes the movement impact of Z axis Compared with previous hydraulic balance system, nitrogen balance system has the following advantages: No external power equipment is needed, saving energy; Adapt to rapid smoothly lifting and lowering in high speed; without noise; improve weight balance and correct the disadvantage of hydraulic system; Dramatically promote precision and smoothness in processing, eliminate micro vibration, and extend the life of screw and motor. | |||

Application Field

|  |  | |

| Reducer housing | Hub | Knuckle | |

|  |  | |

| Flywheel | Brake disc | Bearing ring |