Changsha Tianchuang Powder Technology Co., Ltd |

|

Verified Suppliers

|

|

0.4L-40L Soil grinding Planetary Ball Mill With Sieving Shaker for Analysis of Soil Metal

Overview

Soil grinder often needs to be equipped with 4 agate mill jars for analysis of soil heavy metal . The pressure of agate grinding tank is set through the scale scale. It revolves around its axis at the same time as the rotation of the rotating shaft, and soil samples in the jars collides with each other at high speed in planetary movement, and achieve purpose of crushing, grinding, mixing and dispersing the samples. It can be used for dry grinding, wet grinding or vacuum grinding. The grinder often works with Two or four grinding jars at the same time.

Working Principle

Soil Grinding machine and vibrating sieve machine are used for analyzing heavy metal of soil. The machine is equipped with four agate mill jars installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and soil sample inside the jars are impacted and sheared in high speed movement, and eventually achieving the purpose of crushing, grinding, mixing and dispersing.

Technical specifications

(1) Voltage: 220V AC.

(2) Feed size of soil material:≤ 10MM, Feed size of other materials: ≤3MM

Output particle granularity: The smallest particle size can be reached to 0.1μm .

(3) Rotation speed: Revolution speed: 35-335rpm, rotation speed: 70-670rpm.

(4) Three-phase motor variable frequency controller power: 0.75KW (with power display electronic monitoring device, continuous running time (MIN): forward and reverse rotating cycle (MIN).

(5) Speed regulation mode: stepless speed regulation, automatic timing forward & reverse and automatic stop.

(6) Continuous working hours (full load): 48 hours.

(7) Electric sieve shaker: up to seven layers of sieve screen, diameter 200MM. The screen hole ranges from 20 mesh to 200 mesh (smallest particle size: 20μm ), and times of shaking: 1400 RPM.

Standard configuration of Soil Grinder & Sieve Shaker

(1) Soil Grinder.

(2) 4*250ml agate mill jars and 700 agate balls.

(3) Electric sieve shaker

(4) Sieve screens in 20, 40, 60, 80, 100, 120, 140, 160, 180, 200meshes and 1 pc of base set.

Features of Tencan Soil Grinder & Sieve Shaker

1. Materials can be ground into granularity you expect in high efficiency and high energy and the superfine granule reaches 100 nm.

2. Max grinding acceleration: 100G, the soonest time of grinding: 5 minutes

3. Vertical planetary ball mill meets all kinds of requirements such as wet and dry grinding,

4. vacuum or atmosphere grinding, cryogenic grinding, high temperature grinding, and so on.

5. Available and matched grinding jars and medias made of the following materials for your options: Stainless steel, alumina, zirconia, agate, silicon carbide, nylon, PTFE, PU, tungsten carbide, and etc.

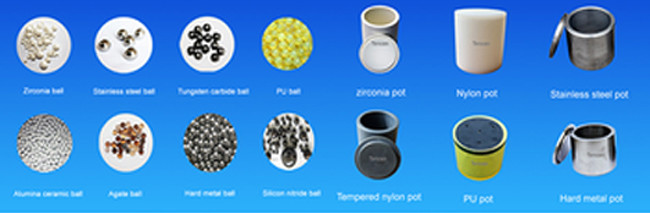

Accessories of Mill Jars & Balls

Available Mill Jars:

304 stainless steel mill jar, 316 stainless steel mill jar, tungsten carbide mill jar, agate mill jar, alumina ceramic mill jar(also called corundum mill jar), zirconia mill jar, nylon mill jar, polyurethane mill jar, Teflon mill jar (PTFE), and etc.

| Recommendation For Matching Solutions About Mill Jars & Materials | |

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. | Vacuum mill jar |

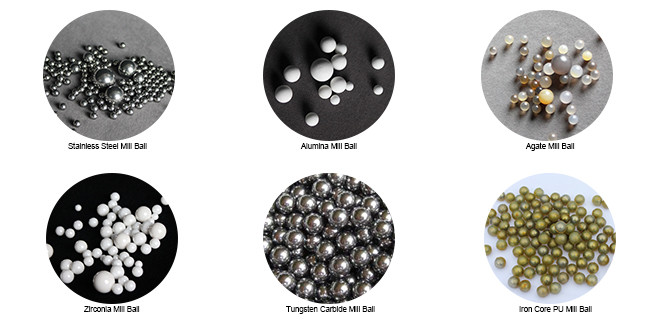

Available Mill Balls:

304 stainless steel mill balls, 316 stainless steel mill balls, tungsten carbide mill balls, agate mill balls, alumina balls, zirconia mill balls, and etc.

| References About Grinding Medias & Materials | ||

| Materials of Grinding Media | Hardness (Mohs) | Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Matching Solutions for Mill Jars & Balls | |||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||

PLANETARY BALL MILL, BALL MILL PRODUCT FOR SOIL SAMPLE, SOIL SAMPLE GRINDING