Changsha Mitrcn Instrument Equipment Co.,Ltd |

|

Rotary Ball Mill Low Noise All Direction Ball Mill / Full Directional Lab Ball Mill

Catalog:

| Model | Voltage | Motor power(KW) | Inverter power KW | Total timing(min) | Alternating Run Time of co-rotation & Reversal Rotation (min) | Rotation speed r/min | Noise ≤db | |

| Revolution speed | Rotation speed | |||||||

| QM-QX0.4L | 220V 50HZ | 0.55 | 0.55 | 1-9999 | 1-9999 | 5-450 | 10-900 | <50db |

| QM-QX1L | 220V 50HZ | 0.75 | 0.55 | 1-9999 | 1-9999 | 5-400 | 10-800 | <50db |

| QM-QX2L | 220V 50HZ | 1.1 | 0.75 | 1-9999 | 1-9999 | 5-400 | 10-800 | <50db |

| QM-QX4L | 220V 50HZ | 1.1 | 0.75 | 1-9999 | 1-9999 | 5-400 | 10-800 | <50db |

| QM-QX8L | 220V 50HZ | 1.5 | 1.5 | 1-9999 | 1-9999 | 5-320 | 10-640 | <50db |

| QM-QX10L | 220V 50HZ | 1.5 | 1.5 | 1-9999 | 1-9999 | 5-320 | 10-640 | <50db |

| QM-QX12L | 380V 50HZ | 1.5 | 2.2 | 1-9999 | 1-9999 | 5-320 | 10-640 | <50db |

| QM-QX16L | 380V 50HZ | 2.2 | 2.2 | 1-9999 | 1-9999 | 5-280 | 10-560 | <50db |

| QM-QX20L | 380V 50HZ | 3.0 | 4 | 1-9999 | 1-9999 | 5-230 | 10-460 | <50db |

| QM-QX40L | 380V 50HZ | 3.0 | 4 | 1-9999 | 1-9999 | 5-220 | 10-440 | <50db |

| QM-QX60L | 380V 50HZ | 4.0 | 5.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | <50db |

| QM-QX80L | 380V 50HZ | 5.5 | 5.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | <50db |

| QM-QX100L | 380V 50HZ | 7.5 | 7.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | <50db |

Application:

It is widely used in geology,mineral,metallurgy,electronic,building

material,ceramic,chemical,light

industry,medicine,beauty,environment production,tea and so

on. Our company have the laboratory with 1000 sets of

application cases and maybe could provide you some suggestion.

Soil: crushing and grinding of soil sand with different physical properties

Fiber: fibrous, crushing and grinding with a certain tensile strength:

Tea, Hay and Other Herbs: Light,Fluffy Crushing and Grinding

High Purity Metal:Granular,Hard,Oxidized High Purity Powder In

Vacuum Atmospheres

Quartzite: Crushing And Grinding Of Granular,Hard Materials

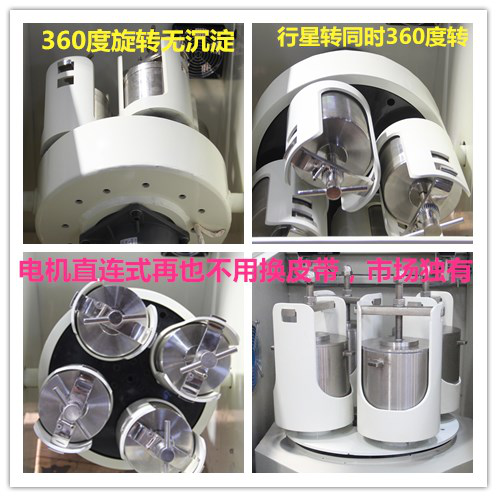

Feature of MITR 360 degree full direction planetary ball mill

1. Window: which could see clearly in the room

2..Pneumatic bar stay: Which bracing the cover on working and convenient and safety operation

3. Damping blanket: Which inlaid on the edge of the cover to prevent the noise and damage when open and close the cover.

4. Operation panel:It is convenient to operate and flexible operation

5. Grinding with four ball mill jars:We adopted the new style pressure bar,the revolution speed is stable and high efficiency and the granularity finer

6. Under high speed working,effectively enhance the air flowing speed of the body and high efficiency loss of heat, ensuring the normal working.

7. Professional design and super function which is 360 degree whole direction revolution. Grinding omnidirectional and more finer

8. Own design of gear and convenient to move.

9. Ensures the consistency and repeat-ability of the experiment.low noise,high efficiency,function comprehensive,small volume.

10. It can solute the problems for the deposition and sticking of some materials and four samples could be obtained with different sizes in one experiment.

11. MITR 360 degree omnidirectional planetary ball mill 2L is the motor direct connection

Techincal parameter:

| Brand Name | MITR  |

| Model | 360 degree rotating omnidirectional planetary ball mill- MITR-QMQX-16L |

| Single Jar Grinding and Total Volume | 10L*4=40L |

| General grinding jar material selection | Metal material selection:304 stainless steel,Tungsten carbide(YG8) |

| Nonmetal material selection:ceramic / corundum / alumina, zirconia, agate | |

| high polymer material selection:Nylon, polyurethane, polytetrafluoroethylene(PTFE) | |

| General grinding ball material selection | Stainless steel,ceramic,corundum,alumina,zirconia, agate, tungsten carbide |

| Maximum loading per jar | Raw material and grinding ball less than 1/3 of grinding jar |

| Feeding granularity | Friable material less than 10mm,others less than 3mm |

| Discharging granularity | minimum up to 0.1μm |

| Grinding Method | Dry grinding / wet grinding / high energy alloying grinding / vacuum grinding(need customized) / low temperature grinding(need customized) |

| Planetary speed (variable frequency adjustable) | Max Revolution 0-220r/min,Rotation 0-440r/miPlanetary total speed:0-660r/min |

| 360 degree speed(variable frequency adjustable) | 1-14/min |

| speed ratio(revolution:rotation) | 1:2 |

| Adjusting speed control method | PLC Frequency conversion control system,Touch screen control system |

| Driving style | Gear drive |

| Grinding ball ratio(the detail ratio contact customer service)The right sheet is just for reference.In fact that we are matching according to the customer requirement. | General grinding over 800 mesh(5mm;10mm;15mm) feeding material less than 3mm |

| Fine grinding 800-1500 mesh(3mm;5mm;10mm;)feeding material less than 1mm | |

| Super fine grinding over 1500 mesh(0.1~10μm)(1mm;3mm;5mm)feeding material less than 200 mesh | |

| Voltage | 380V 50 HZ |

| Motor Power | 5.5Kw |

| Working method | Two or four jars working at the same time |

| Maximum continue working time | 72h(Timing 0-9999h) |

| Programmed control | The ball grinding used for high-tech micro computer chip control.It can run alternately for positive turn and reverse turn(0-999min), and run alternately for positive turn and pause,reverse and pause,and than positive run. It is especially suitable for cooling or intermittent operation. |

| Weight | 500kg |

| Dimension | 130*140*160cm |

| Features (direct motor connection) | The only one which have the drive mode with speed reducer with motor direct drive in the market,have replaced of traditional belt drive mode.In the past, the ball mill was mainly driven by a belt, and all the gravity is on the belt. After running for a long time, the belt is easy to aging, skid, fracture and so on. There is the direct speed reducer with motor to installed into the planetary master disk in our company,its stability is more 5 times higher than that of belt.And also there is no belt replacement every 3 months during the later maintenance.It has applied for patent protection for planetary ball mill with motor direct drive. |

Mill jars and Mill balls

Our factory can provide 304 stainless steel jar,Tungsten carbide jar(YG8),ceramic jar,corundum/alumina jar, zirconia jar, agate jar.nylon jar, PU jar, PTFE jar.We can also provide the balls material of stainless steel,ceramic,corundum,alumina,zirconia,agate, tungsten carbide.

Grinding Media

Changsha Mitrcn Instrument Equipment Co., Ltd. specializes in designing, manufacturing and selling experimental equipment. Supported by the state key laboratory of Central South University Powder Metallurgy with Hunan University, Shanghai Jiao tong University and other well-known universities to maintain long-term close technical exchanges and product development cooperation.

The high-tech talents in our company are: doctor, master, eight senior engineer,eight senior technician, ten engineer,six technician.The main business is the R&D, production and sale of experimental equipment and related technical consultation services.