Danyang Kaixin Alloy Material Co., Ltd. |

|

Verified Suppliers

|

|

KX Monel R405 Sheet Welding Wire Strip Round Bar Light Rod Process Performance On Monel Alloy

Product Description and Application

Monel R405 is also known as UNS N04405

Monel R405 is an easy-to-machine version of alloy Monel 400. Alloy Monel 405 adds a certain amount of sulfur, the sulfide produced in the machine has chip breaking effect, so it is suitable for automatic nut machine. Like alloy Monel 400, alloy 405 can withstand the corrosion of seawater, steam and alkaline solutions at high temperatures.Monel 405 is a solid solution and can only be hardened by cold working. The nickel-based alloy also shows excellent corrosion resistance, weldability and high strength. The alloy corrosion rate is very low in fast-moving brine solutions and seawater environments and it can withstand stress corrosion cracking well in fresh water environments. Excellent corrosion resistance makes it useful in Marine and non-oxidizing chloride solution environments.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Element | Composition limits, % |

| Ni | 63.0min |

| Cu | 28min~34max |

| Fe | 2.5max |

| Mn | 2.0max |

| C | 0.3max |

| Si | 0.5max |

| S | 0.025min-0.060max |

| Density | 8.80g/cm3(0.318 lb / in3) | |

| Elasticity Modulus | 26 000 ksi | |

| Heating Energy | 0.427 J/g-°C | |

| Magnetism | 200H(At 70 F) | |

Coefficient of Thermal Expansion, in./in./ F x 106 | 70-200F | 7.7 |

| 70 - 400 F | 8.6 | |

| 70 - 800 F | 8.9 | |

| 70 - 1000 F | 9.1 | |

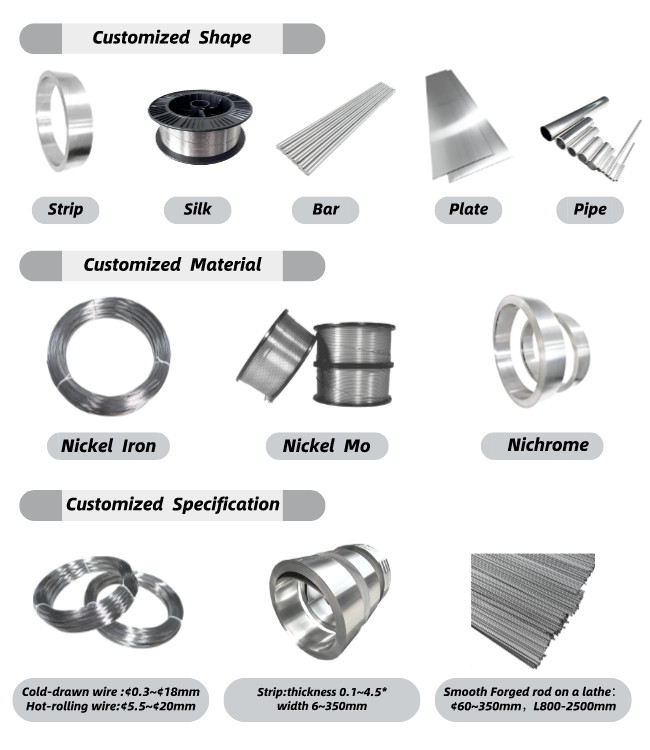

Professional Customization

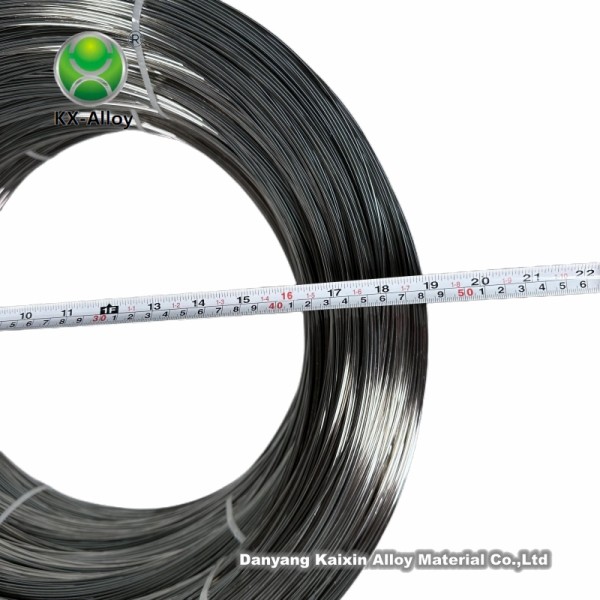

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |